Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 45

Plan the Kinetix 5500 Drive System Installation Chapter 2

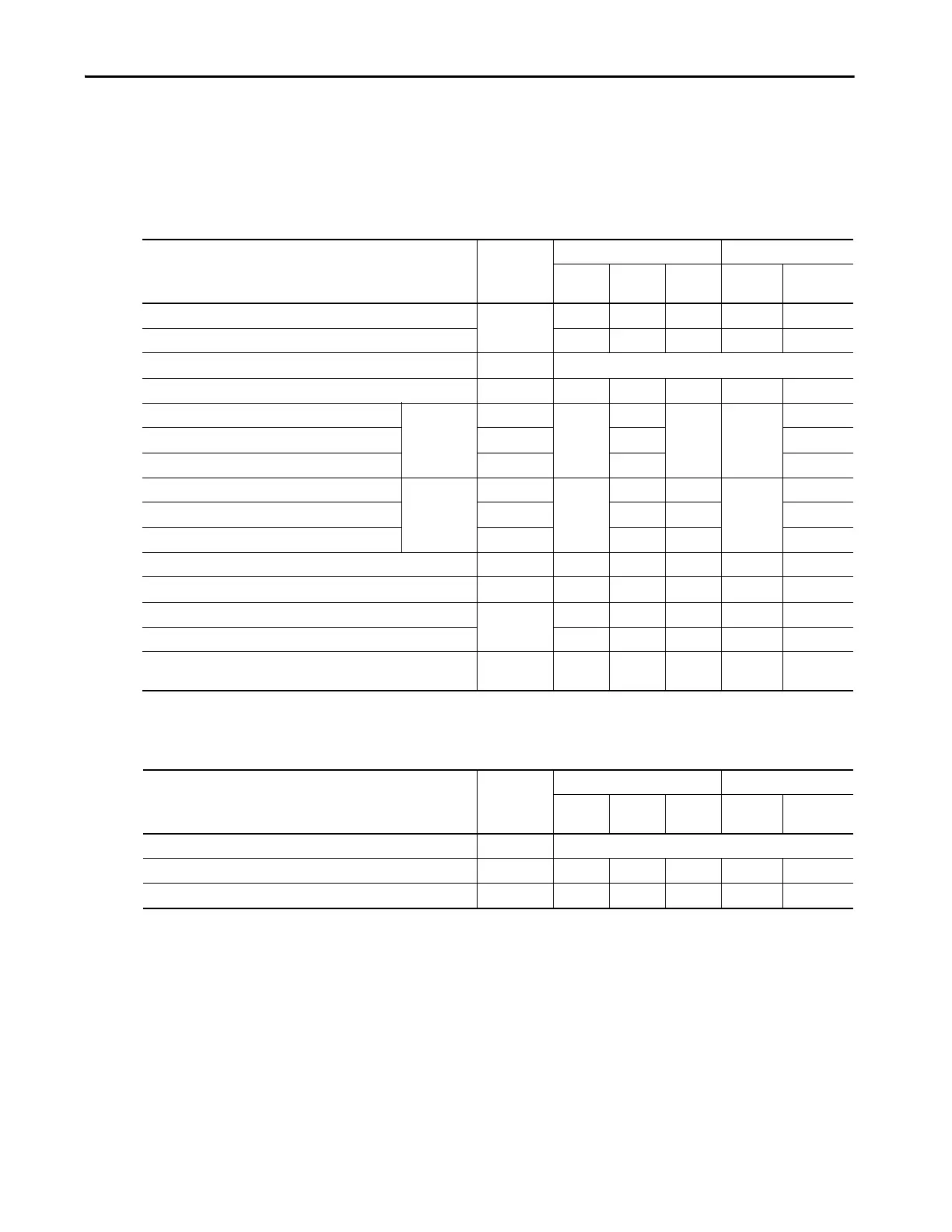

Cable Categories for Kinetix 5500 Systems

These tables indicate the zoning requirements of cables connecting to the

Kinetix 5500 drive components.

Table 15 - Kinetix 5500 Drive

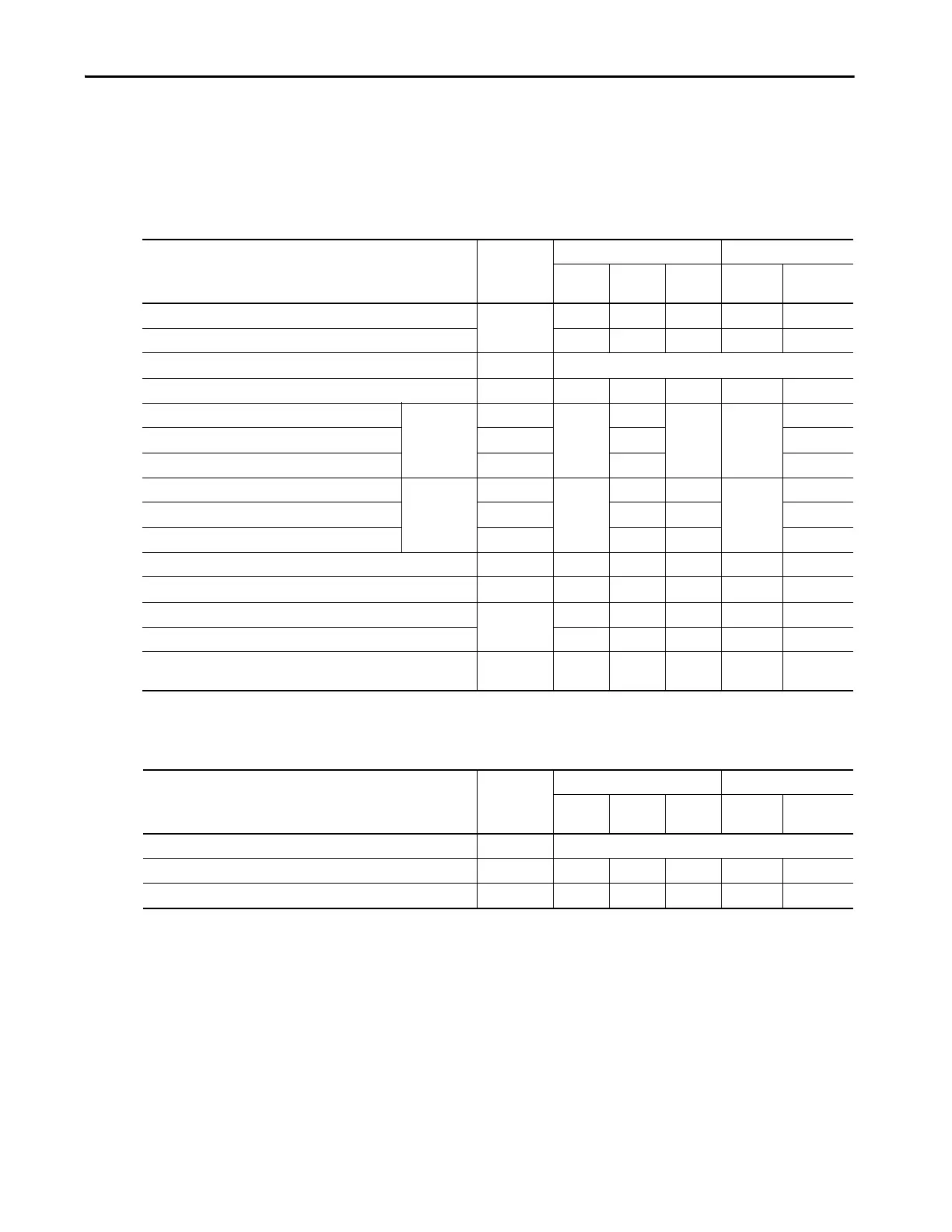

Table 16 - Capacitor Module

Wire/Cable Connector

Zone Method

Very

Dirty

Dirty Clean

Ferrite

Sleeve

Shielded

Cable

L1, L2, L3 (shielded cable)

IPD

–X–– X

L1, L2, L3 (unshielded cable) X – – – –

DC-/DC+ (DC bus) DC Bus-bar only, no wiring connector.

DC+/SH (shunt) RC – X – – –

U, V, W (motor power)

Kinetix VP

motors/

actuators

MP

–

X

––

X

Motor feedback MF X X

Motor brake BC X X

U, V, W (motor power)

MP-Series™

motors/

actuators

MP

–

X–

–

X

Motor feedback

(1)

MF – X X

Motor brake BC X – X

24V DC CP – X – – –

Safety enable for safe torque-off (hardwired)

(2)

STO – X – – –

Registration input

IOD

––X– X

Dedicated digital inputs (other than registration inputs) – X – – –

Ethernet

PORT1

PORT2

––X– X

(1) When the 2198-H2DCK converter kit is used, the feedback cable routes in the clean wireway.

(2) STO connector applies to only 2198-Hxxx-ERS (hardwired) servo drives.

Wire/Cable Connector

Zone Method

Very

Dirty

Dirty Clean

Ferrite

Sleeve

Shielded

Cable

DC-/DC+ (DC bus) DC Bus-bar only, no wiring connector.

24V DC CP – X – – –

Module status MS – X – – –

Loading...

Loading...