Introduction Parameter x.00

Parameter

description format

Keypad and

display

CT Modbus

RTU

User

programming

CT Soft Menu 0

Advanced parameter

descriptions

Menu 12

Commander SK Advanced User Guide 137

Issue Number: 2 www.controltechniques.com

The current magnitude is compared to an upper and lower threshold by a comparator with hysteresis to give torque present and drive output open

detection functions respectively. The upper and lower threshold currents are given as a percentage of motor current defined by Pr 5.07 (or Pr 21.07 if

motor map 2 is selected). The upper threshold should be set to the current level that indicates that there is magnetising current and sufficient torque

producing current in the motor to deliver the required amount of torque when the brake is released. The output of the comparator remains active after

this level has been reached unless the current subsequently falls below the lower threshold which should be set to the required level to detect the

condition where the motor has been disconnected from the drive. If the lower threshold is set greater or equal to the upper threshold, the upper

threshold applies with a hysteresis band of zero. If Pr 12.42 and Pr 12.43 are both set to zero then the output of the comparator is always one.

The frequency comparator can be used to detect when the motor frequency has reached a level where the motor can produce the required amount of

torque to ensure that the motor rotates in the demanded direction when the brake is released. This parameter should be set to a level slightly above

the motor slip frequency that is likely to occur under the highest expected load that is applied to the motor when the brake is released.

The brake apply frequency threshold is used to ensure that the brake is applied before the motor frequency reaches zero and to prevent the motor

rotating (in the reverse direction due to an overhauling load for example) during the brake apply time. If the frequency falls below this threshold, but

the motor is not required to stop (i.e. reversing direction without stopping), provided the reference on Pr 1.11 remains at one, the brake is not applied.

This prevents the brake from activating and de-activating as the motor passes through zero speed.

The pre-brake release delay is used to allow time for the motor torque to reach the required level before the brake is released. This time should allow

for the motor flux to reach a significant proportion of the rated level (2 or 3 times the rotor time constant of the motor), and the time for slip

compensation to become fully active (at least 0.5s). During the Pre-brake delay period the frequency reference is held constant (Pr 2.03 = 1).

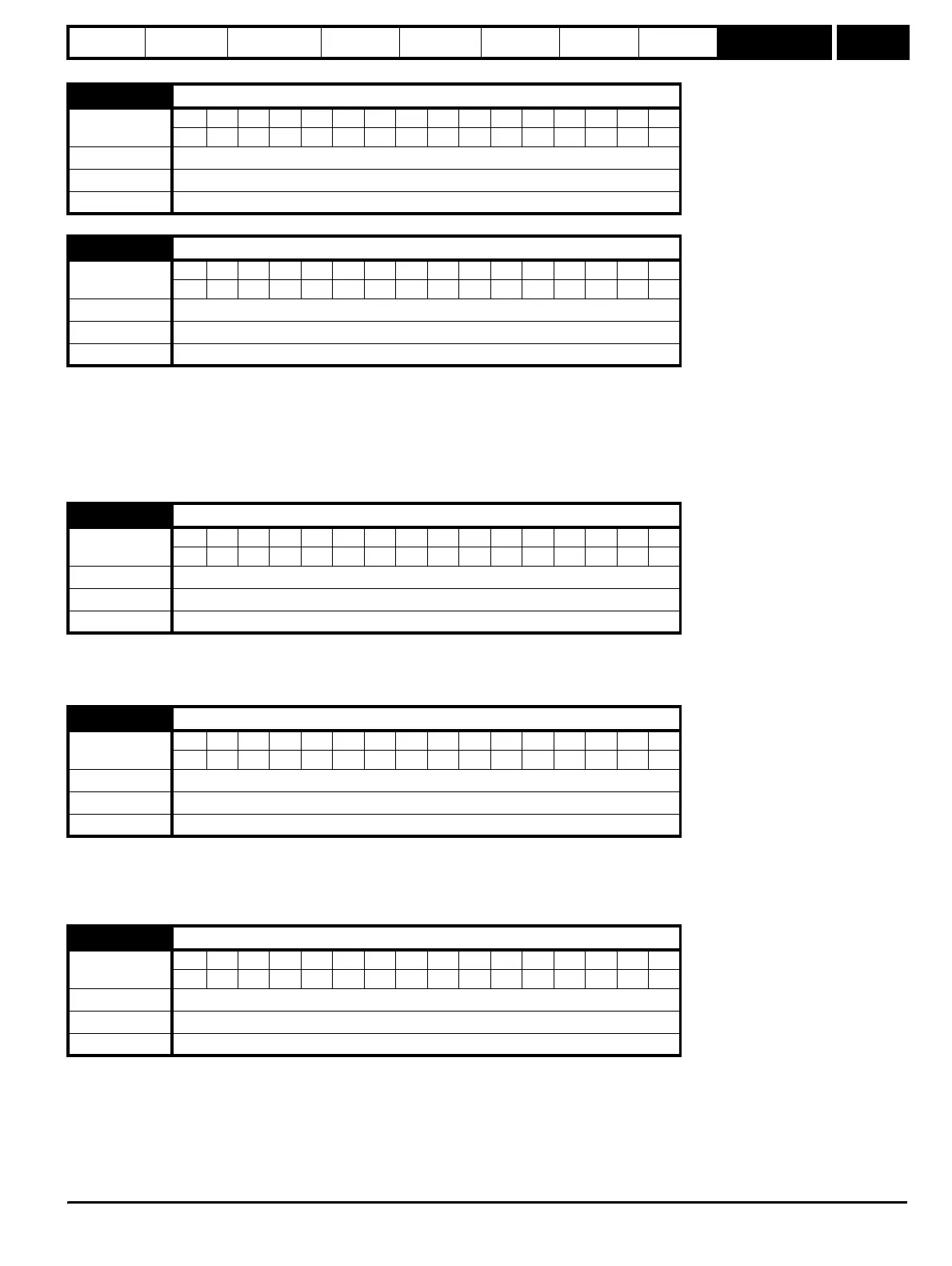

12.42 Brake release current threshold

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Range 0 to 200 %

Default 50

Update rate 21 ms

12.43 Brake apply current threshold

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Range 0 to 200 %

Default 10

Update rate 21 ms

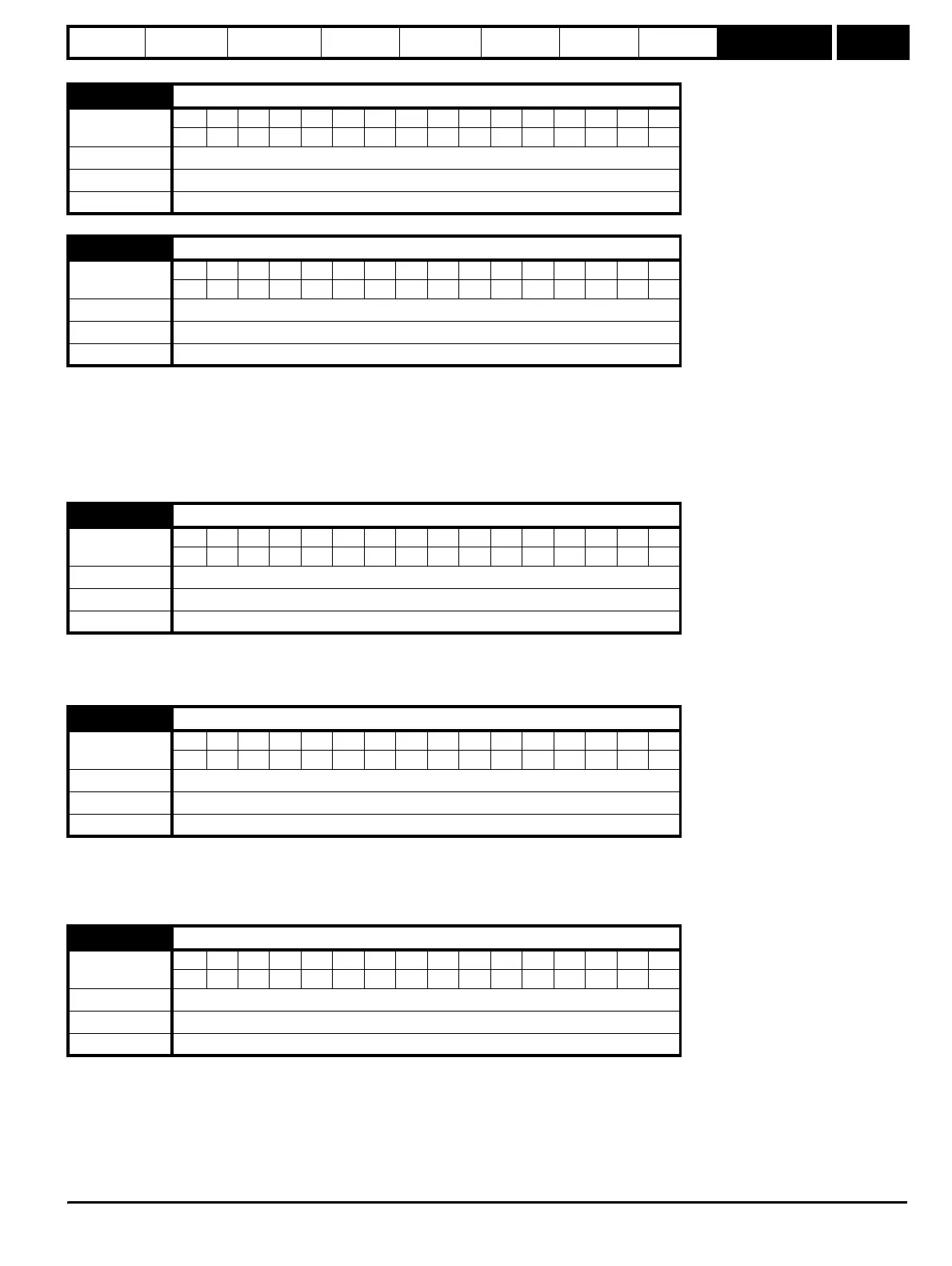

12.44 Brake release frequency

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1 111

Range 0 to 20.0 Hz

Default 1.0

Update rate 21 ms

12.45 Brake apply frequency

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1 111

Range 0 to 20.0 Hz

Default 2.0

Update rate 21 ms

12.46 Pre-brake release delay

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1 111

Range 0.0 to 25.0 s

Default 1.0

Update rate 21 ms

Loading...

Loading...