Introduction Parameter x.00

Parameter

description format

Keypad and

display

CT Modbus

RTU

User

programming

CT Soft Menu 0

Advanced parameter

descriptions

Menu 4

Commander SK Advanced User Guide 49

Issue Number: 2 www.controltechniques.com

The current demand is derived from the torque demand. Provided the motor is not field weakened the torque and current demands are the same. In

field weakening the current demand is increased with reduced flux:

The current demand is subject to the current limits.

This parameter defines the current limit as a percentage of the rated active current. When the motor rated current is set lower than the drive rated

current, the maximum value of this parameter increases to allow larger overloads.

Therefore, by setting the motor rated current to a lower value than the drive rated current, it is possible to have a current limit greater then 165%. An

absolute maximum current limit of 999.9% is applied.

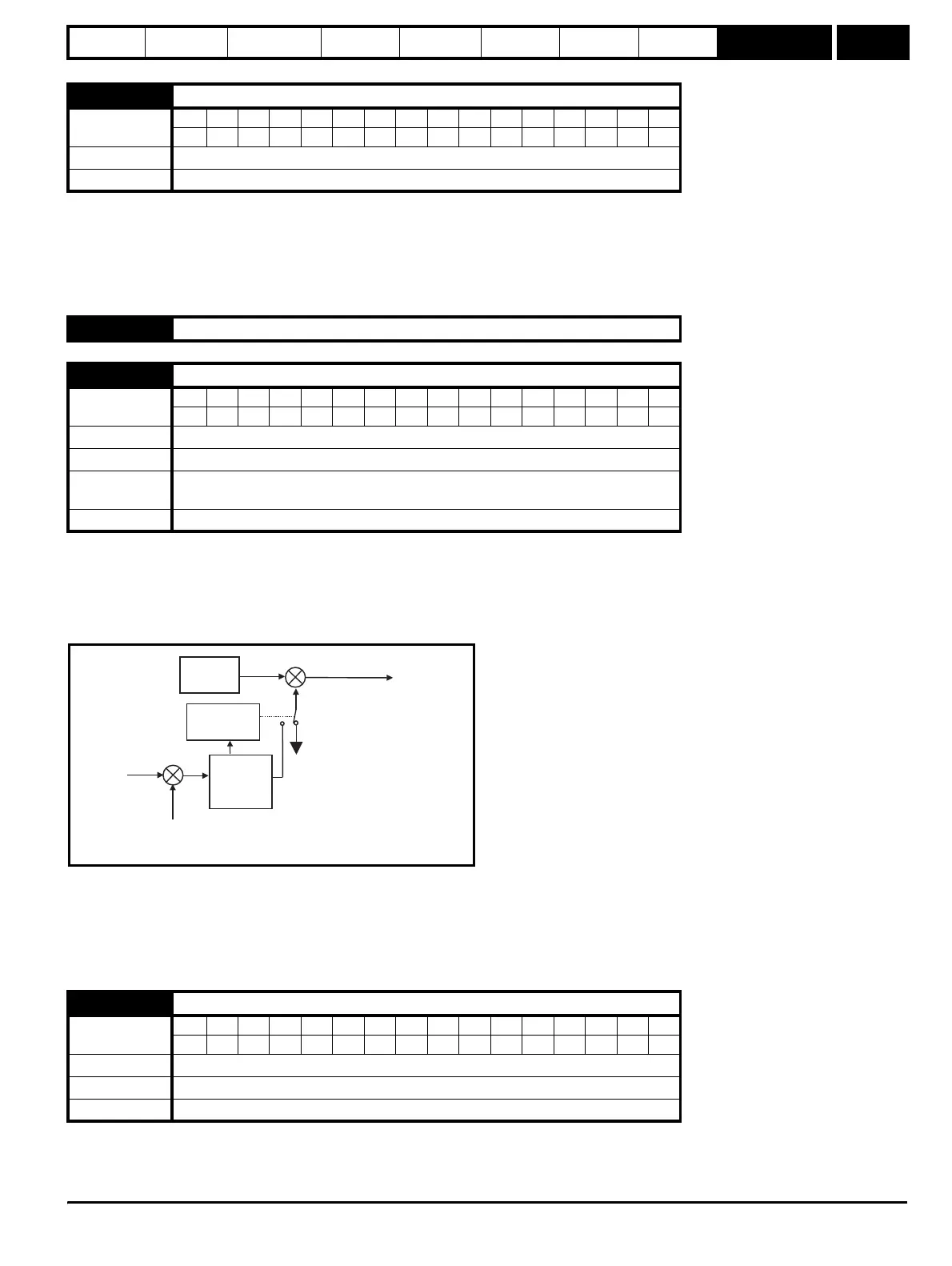

In frequency control mode (Pr 4.11 = 0), the drive output frequency is modified if necessary to keep the active current within the current limits as

shown below:

The active current limit is compared with the active current and if the current exceeds the limit the error value passes through the PI controller to give

a frequency component which is used to modify the ramp output. The direction of the modification is always to reduce the frequency to zero if the

active current is motoring, or to increase the frequency towards the maximum if the current is regenerating. Even when the current limit is active the

ramp still operates, therefore the proportional and integral gains (Pr 4.13 and Pr 4.14) must be high enough to counter the effects of the ramp. For

method of setting the gains see Pr 4.13 and Pr 4.14 on page 50.

In torque control mode the current demand is limited by the active current limit. For operation of this mode see Pr 4.11 on page 50.

This is the main torque reference parameter. A positive value is required for torque to be applied in the forward direction, and a negative value is

required for torque to be applied in the reverse direction.

For a negative value, program a digital input to the analog input invert bit. This will give a negative value on the analog input destination parameter.

4.04 Current demand

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1 11111

Range ±TORQUE_PROD_CURRENT_MAX %

Update rate Background

4.05 to 4.06 Unused parameters

4.07 Symmetrical current limit

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

11 1 111

Range 0 to MOTOR1_CURRENT_LIMIT_MAX %

Default 165.0

Second motor

parameter

Pr 21.29

Update rate Background

4.08 Torque reference

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

11 11

Range ±USER_CURRENT_MAX %

Default 0.0

Update rate Background

Current demand

Output frequency (Pr 5.01)

Rated frequency (Pr 5.06)

---------------------------------------------------------------------------=

PPr4.13

IPr4.14

Current limit

active

1

0

Active

current

limit

Post ramp

reference

Ramp

Active

current

-

+

Loading...

Loading...