System manual CECX / EC directives and standards

12.1 Why EMC-compatible wiring?

The interference immunity of an electrical system is crucially dependent on

EMC-compatible wiring and shielding. Experience in service shows that in-

adequate wiring and shielding of plant components are the most frequent

causes of faults and plant failures.

Faults caused by EMC are much more difficult to deal with than "conven-

tional" malfunctions:

Due to the type of symptom that occurs, they are often not recognized

as such and often resemble a fault in a module that is actually working

correctly.

They typically occur intermittently and are difficult to reproduce.

Troubleshooting is correspondingly complex and expensive.

Thus, from the very beginning, make sure you pay attention to careful

wiring and shielding in accordance with the guidelines described be-

low.

12.1.1 Basic structure of EMC measures

The EMC concept for the entire CECX modular control system is designed

in such a way that each module can independently withstand the influences

that occur in an electro-magnetically affected industrial environment.

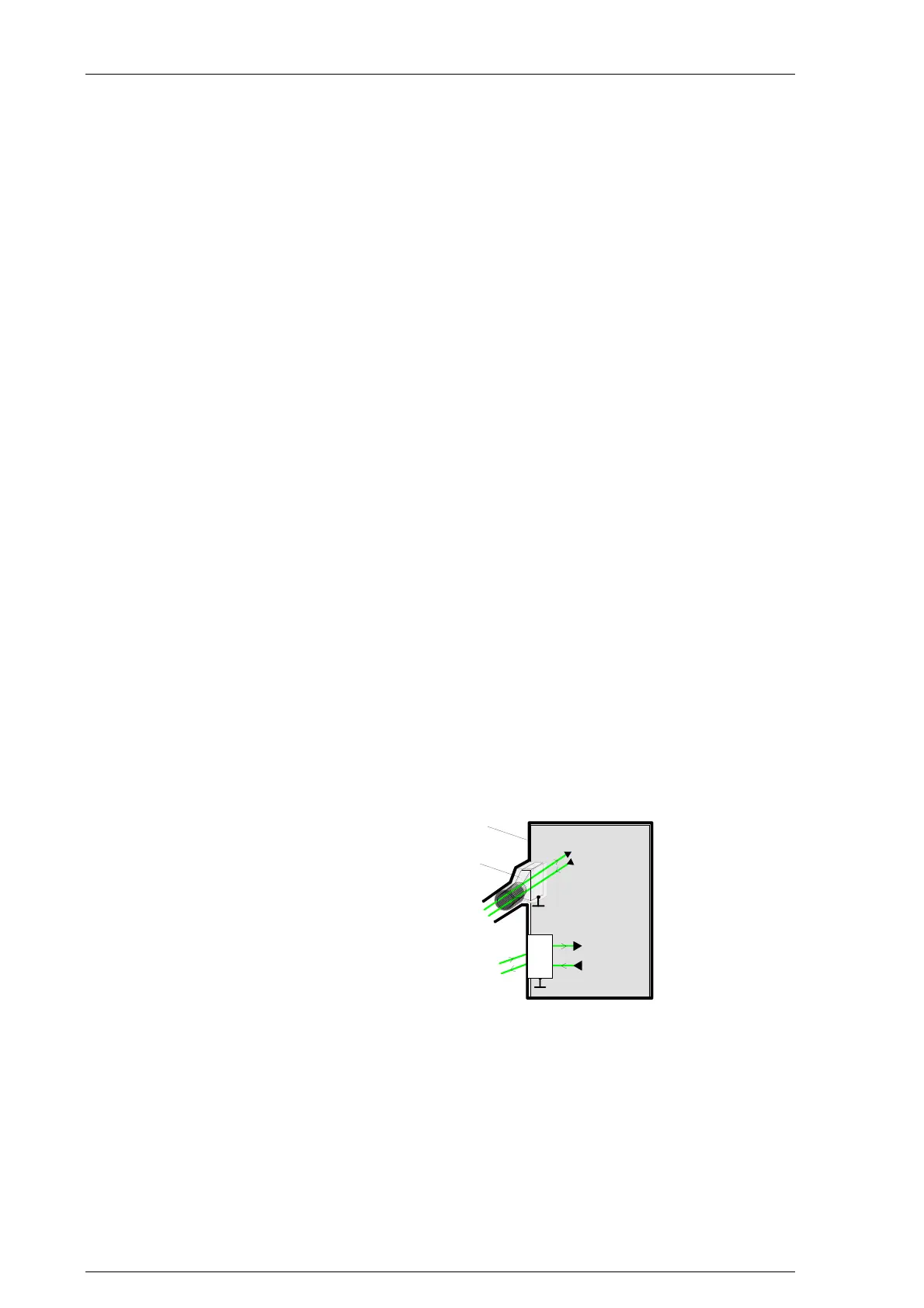

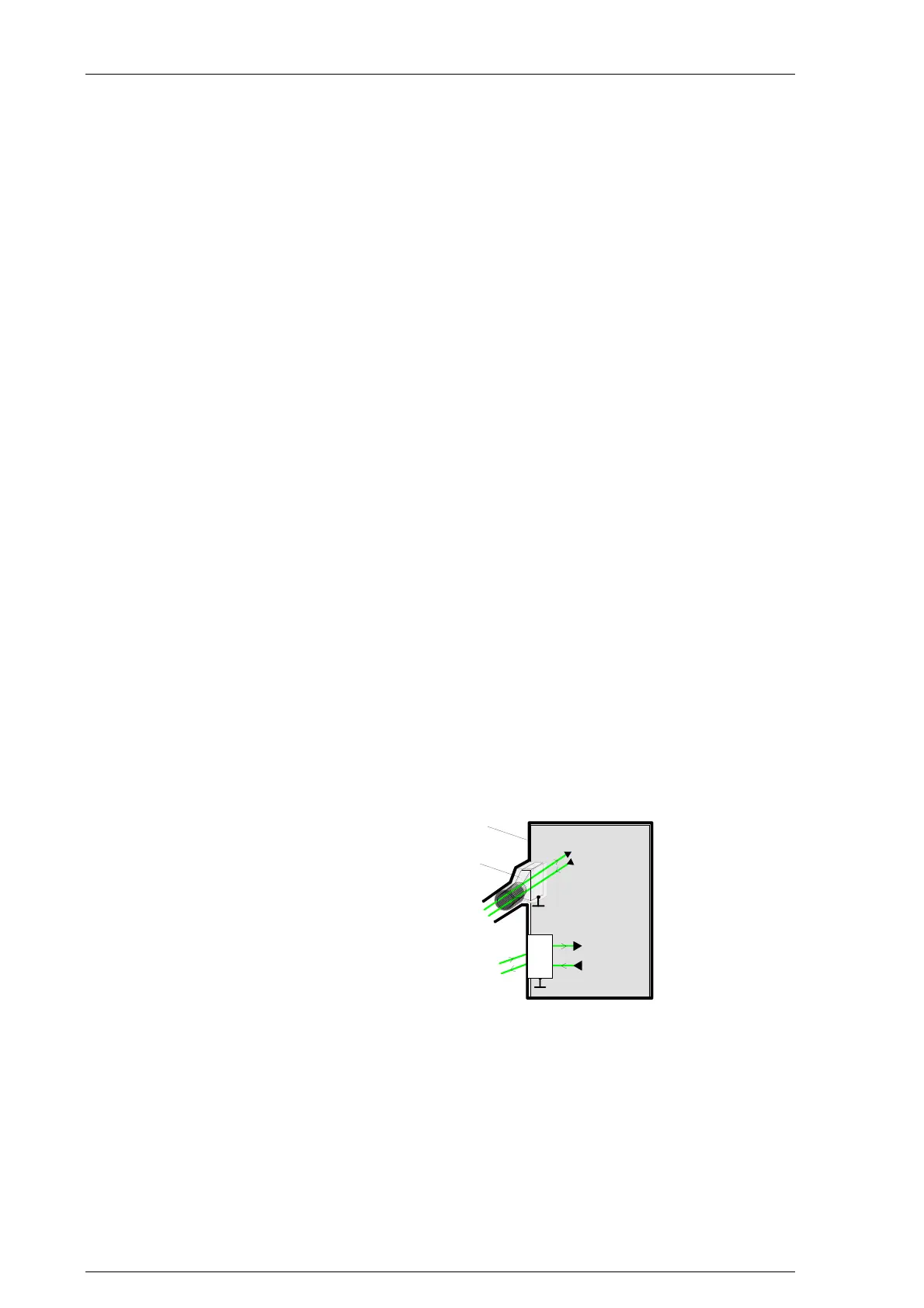

A closed shield casing is assumed. This shield cover is correspondingly

expanded by shielded interfaces or, if unshielded interfaces are used, the

open shield cover is “closed” again via a filter (see figure).

GND

Shield connected to

GND via connector

shielded

interface

unshielded

interface

"Closed"

shield casing

print

filter

Corresponding connections on the modules are provided for shielded inter-

faces. It is therefore not necessary to connect this cable shield with the sys-

tem via additional shield clamps.

Unshielded interfaces are filtered at their connection points according to

their useful signal. Thus, it is not necessary to additionally filter these lines.

CECX-II 12-2

Loading...

Loading...