The Festo_PartDetector.lib library

10

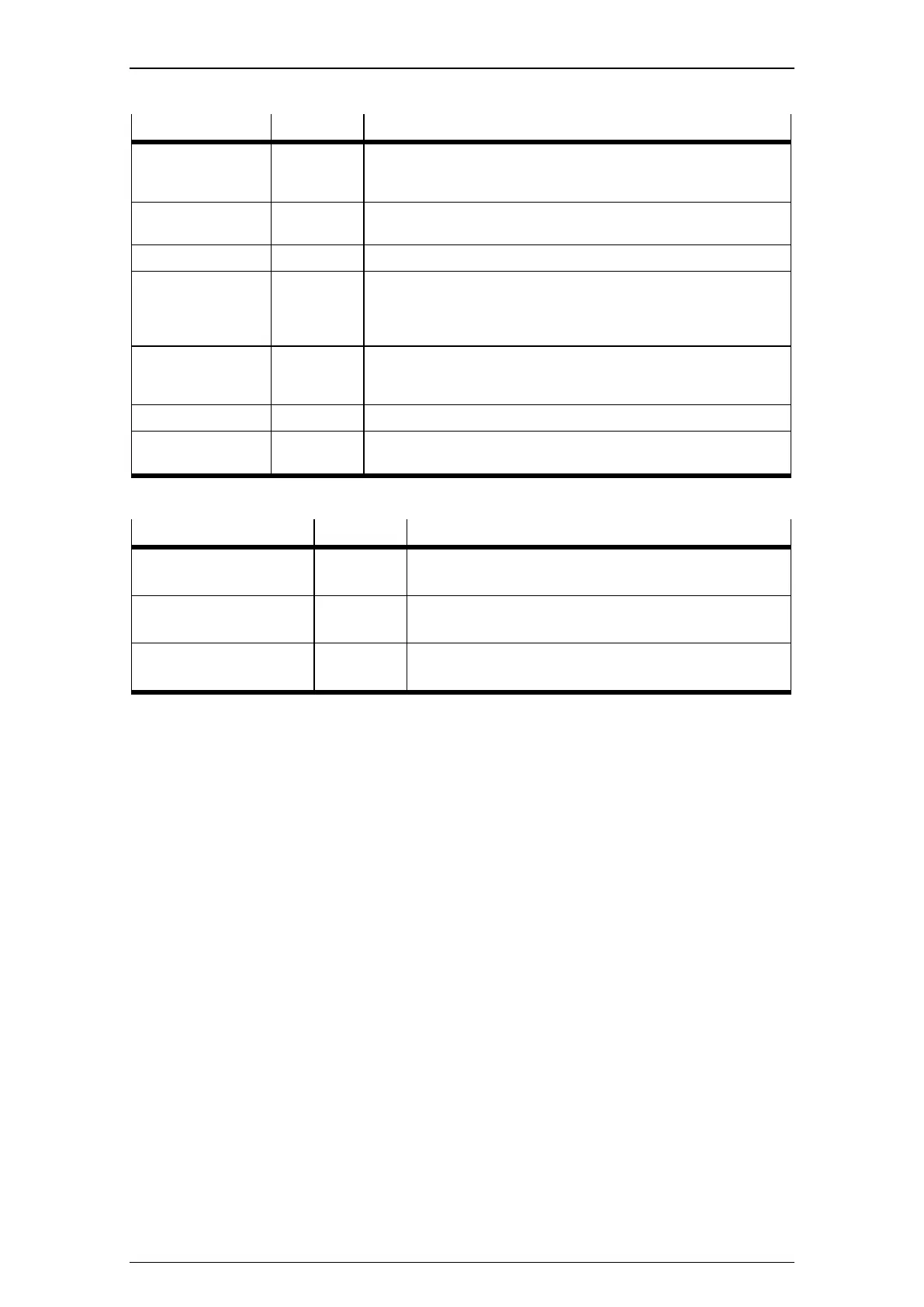

1.6 Interfaces – Inputs

Input Type Description

Connect BOOL If there is a rising edge, the module takes the created access data

and attempts to log in. If there is a falling edge, the module

attempts to log out.

StartDetection BOOL The taking of pictures and processing runs continuously as long as

this input is TRUE.

SinglePicture BOOL If there is a rising edge, a single picture is taken.

MinPictureDistance LREAL Specifies the minimum distance between two successive pictures.

The frequency of the pictures is thus also specified indirectly. If the

distance between two pictures is significantly greater than

MinPictureDistance, the maximum frame rate could be used.

ResetIDCounter BOOL If there is a rising edge, the counter for the part ID is set to the

value IDResetValue+1. The part ID is an identification number,

which is assigned to each newly detected part.

IDResetValue DINT ResetIDCounter.

ClearInternalBuffer BOOL A rising edge causes clearing of the internal buffer for duplicate

part detection.

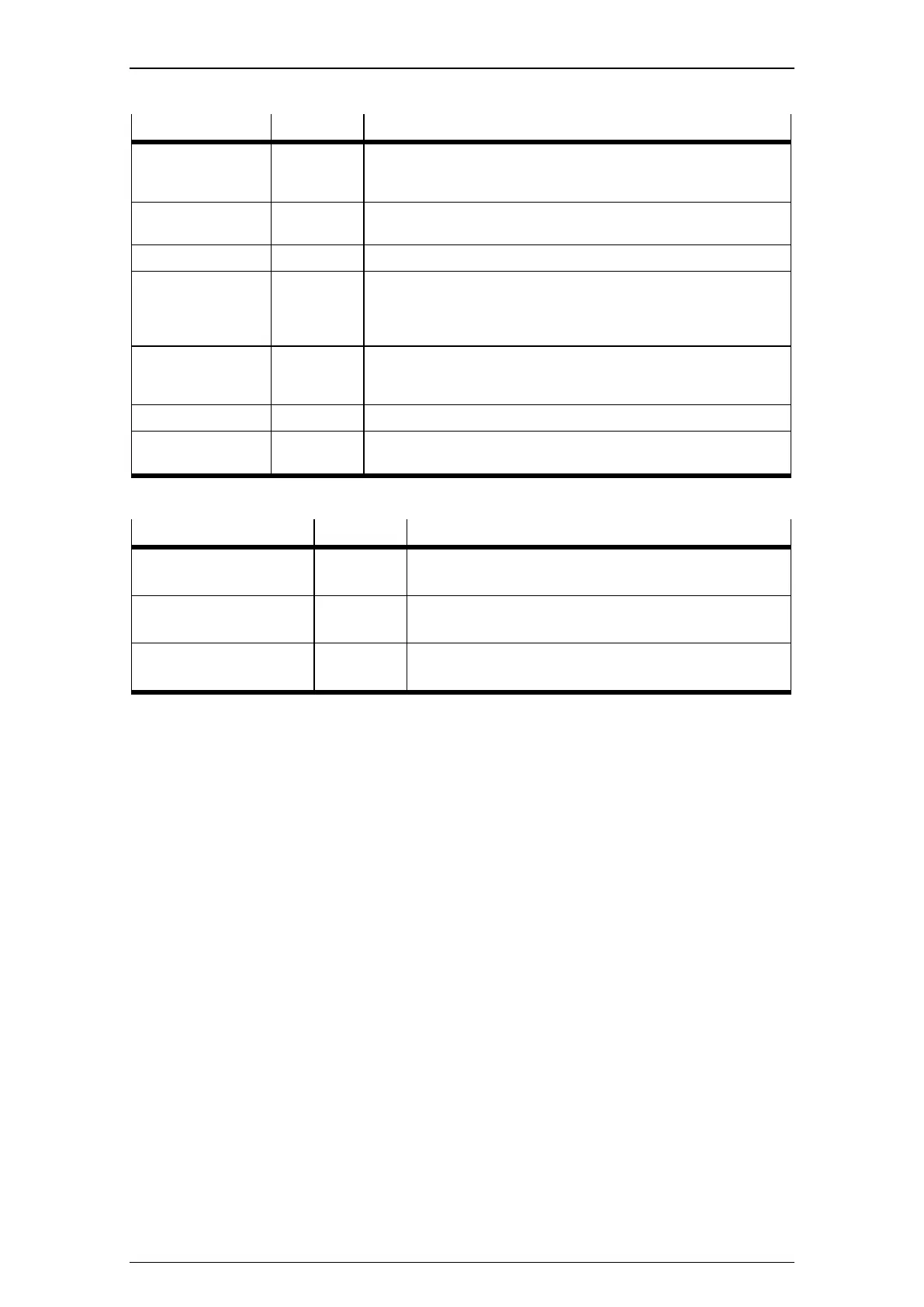

1.6.1 Settings for the detection of parts detected multiple times

Input Type Brief description

DuplicateDetectionEnabled

Default: TRUE

BOOL Default for the recognition of parts on the conveyor.

PositionTolerance

Default: 1

LREAL Tolerance range for the recognition of parts on the

conveyor.

ConveyorLimit

Default: 1000

LREAL Maximum distance for saved parts on the conveyor in the

allPartsList array.

DuplicateDetectionEnabled

If the DuplicateDetectionEnabled parameter is TRUE, parts are only output as "new parts" if they were not

already detected at the same position on the conveyor. Previously detected parts are saved in the

allPartsList array.

If the DuplicateDetectionEnabled is FALSE, all detected parts are output as "new parts" for each picture.

Furthermore, they are not saved in the allPartsList array.

PositionTolerance

Given the fact that the part position when detected by the Compact Vision System can vary slightly

(particularly if the conveyor position is changed), a tolerance range must be specified. The tolerance range

specifies the maximum value (e.g. in mm) by which the part position can deviate from the assumed part

position without the part being interpreted as a new part. The tolerance range is set in global coordinate

units.

Example

A part is detected at the position (X= 40 mm / Y= 50 mm). The conveyor moves 100 mm in the X direction.

(X= 140 mm / Y= 50 mm) is expected as the new position for the part. However, due to visual effects and

inaccuracies in the calculation, the part is detected at the position (X= 142 mm / Y= 49 mm).

– If the PositionTolerance parameter = 1 (mm) or less, the part is detected as a new part, as the

tolerance range for X extends from 139 mm to 141 mm (40 mm + 100 mm +/– 1 mm). The part is thus

incorrectly detected as a second (new) part and output.

– If the PositionTolerance parameter = 2 (mm) or more, the tolerance range extends from 138 mm to

142 mm (40 mm + 100 mm +/– 2 mm). The part position is thus within the tolerance range, whereby it

assumed that only the part has moved. Only one part is then correctly output.

Loading...

Loading...