6 - 12

PN 074-550-P1D

SQC-310 Operating Manual

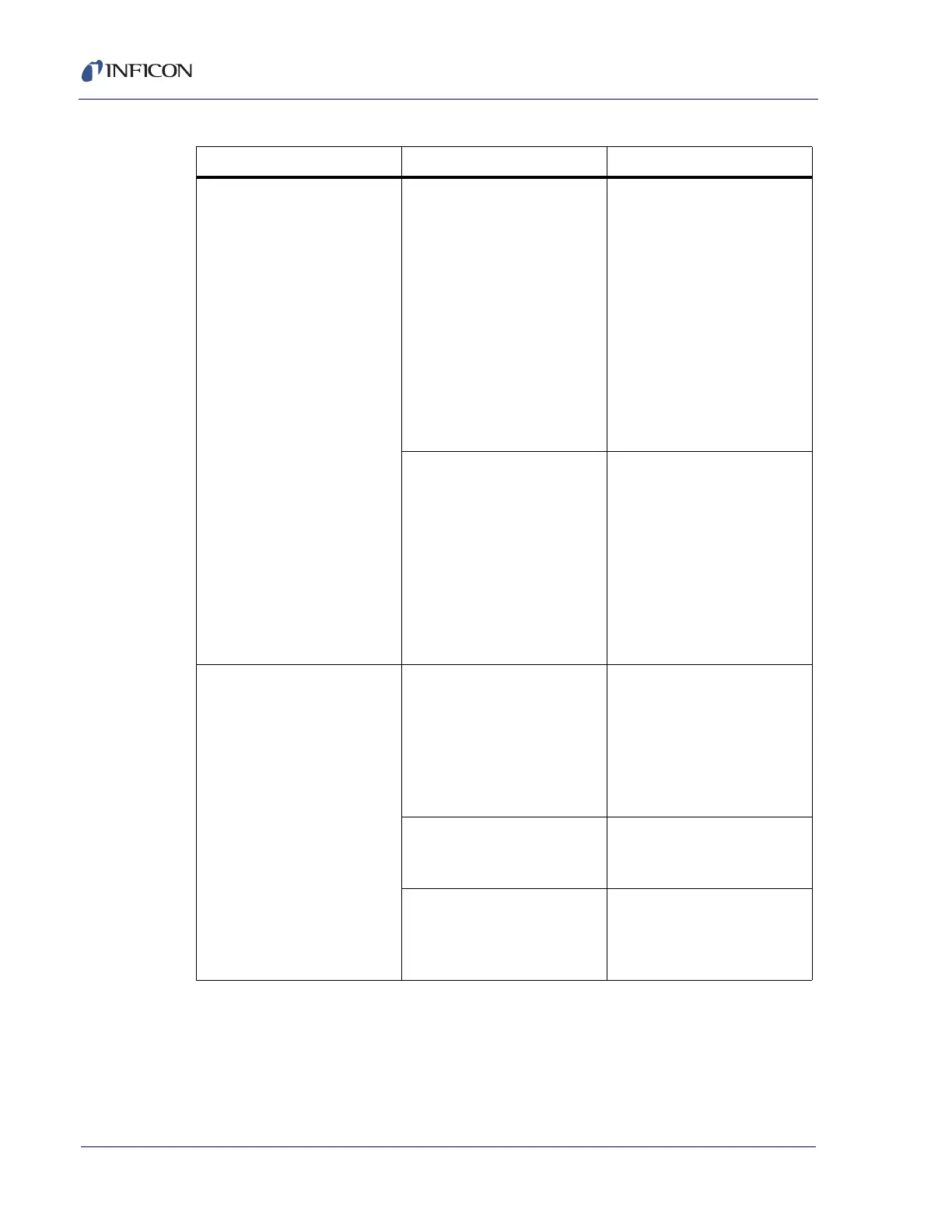

Thickness reproducibility

is poor.

Erratic evaporation flux

characteristics.

Move sensor to a different

location.

Check the evaporation

source for proper operating

conditions.

Ensure relatively constant

pool height and avoid

tunneling into the melt.

Assign multiple sensors to

the source.

Material does not adhere well

to the crystal.

Check for contamination on

the crystal surface.

Evaporate an intermediate

layer of appropriate material

onto the crystal to improve

adhesion.

Use gold, silver, or alloy

crystals, as appropriate.

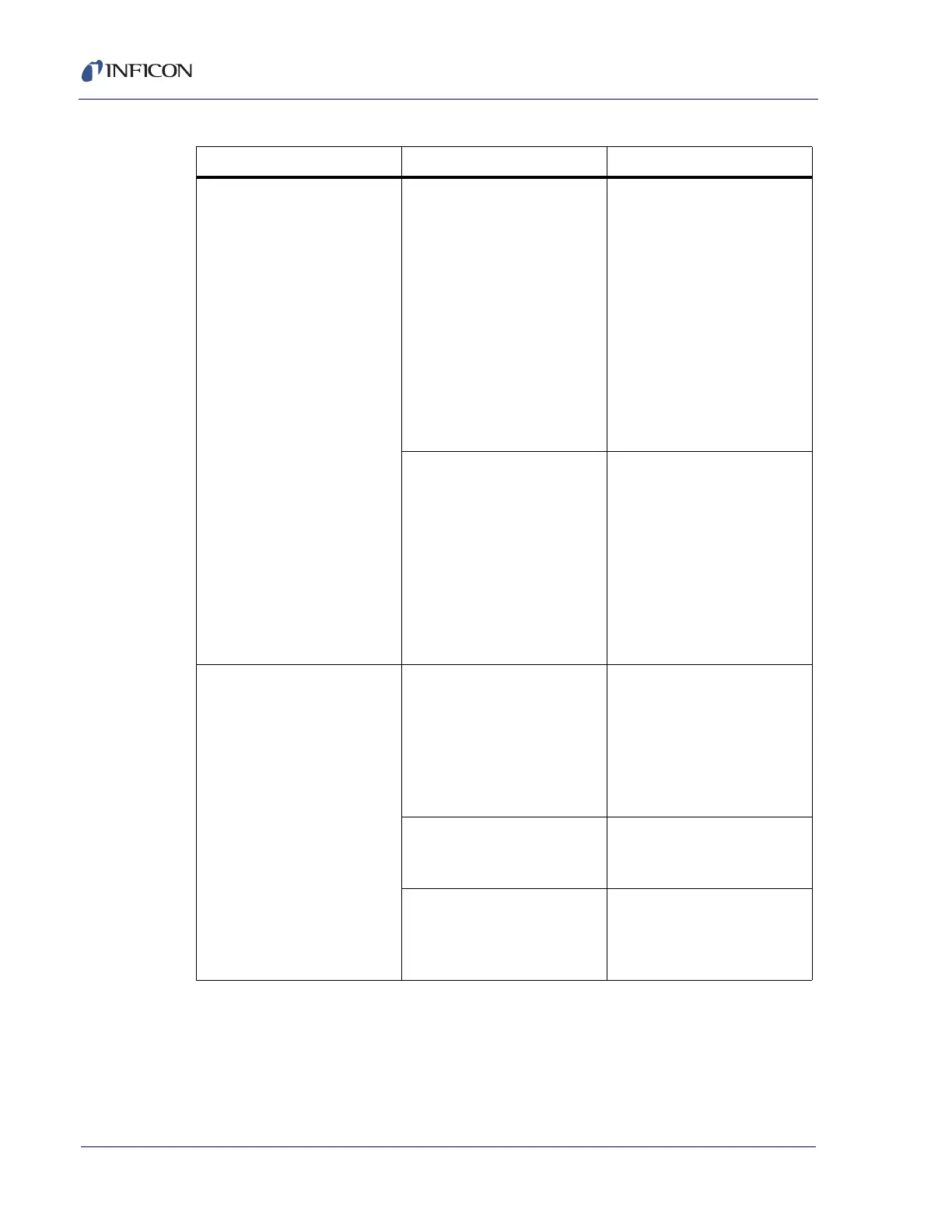

Rate control is poor. PID control loop parameters

are not optimized.

Test in Manual mode to

ensure a stable rate is

possible.

Change PID control loop

parameters (see section 7.5

on page 7-5).

Period and/or Rate Filter

Alpha parameters are not

optimized.

Change Period and/or Rate

Filter Alpha values (refer to

section 3.12 on page 3-25).

Electron beam sweep

frequency “beating” with the

SQC-310 measurement

frequency.

Adjust the sweep frequency

so it is not in phase with the

SQC-310 measurement

frequency.

Table 6-1 Symptom/Cause/Remedy Chart (continued)

SYMPTOM CAUSE REMEDY

Loading...

Loading...