• A characteristic feature of the main axis system is that, among other

things, the maximum possible inertia occurs about one of the 3 coordi-

nate axes.

More information is contained in the KUKA.Load documentation.

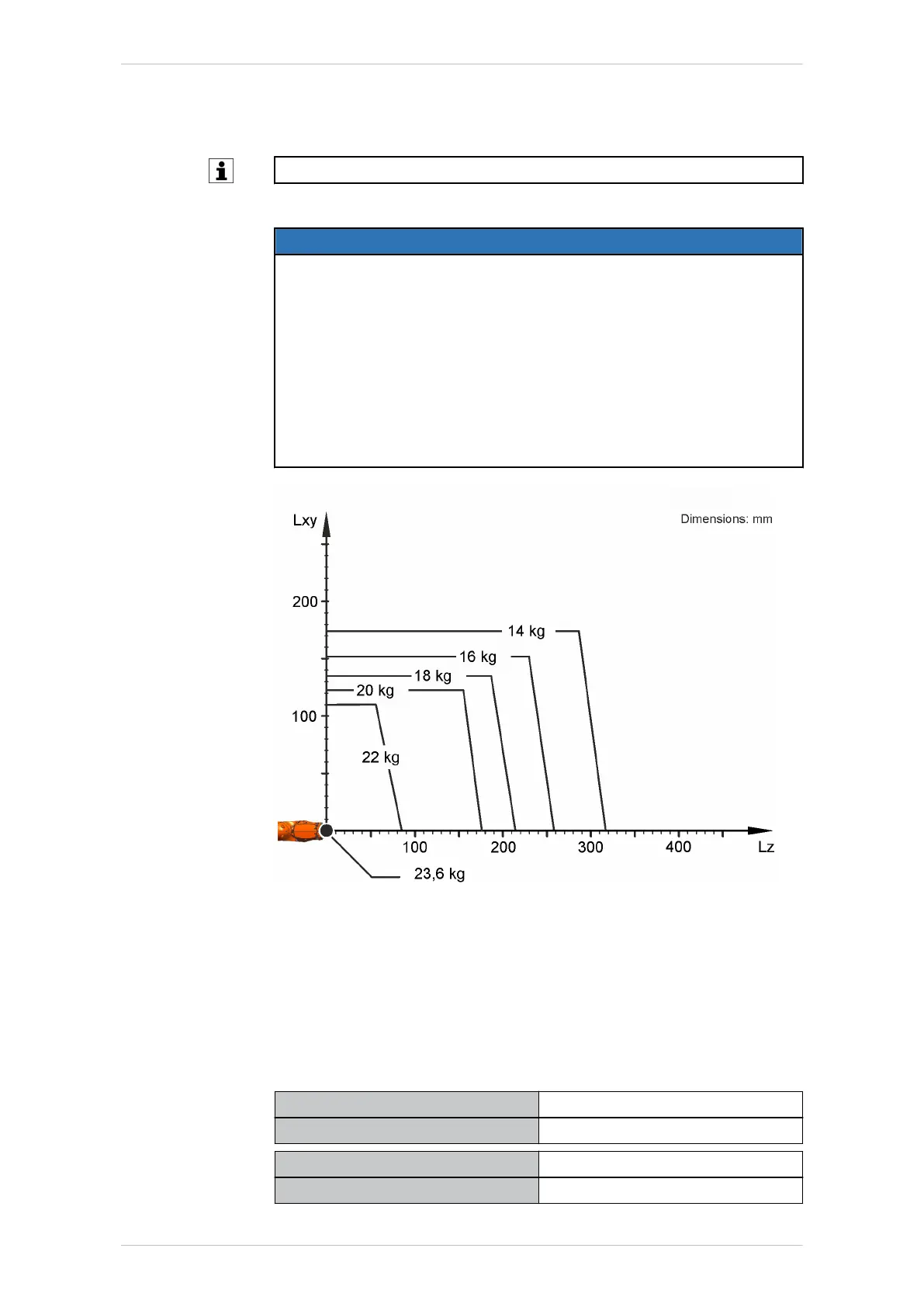

Payload diagram

NOTICE

This loading curve corresponds to the maximum load capacity. Both val-

ues (payload and mass moment of inertia) must be checked in all ca-

ses. Exceeding this capacity will reduce the service life of the robot and

overload the motors and the gears; in any such case KUKA Deutsch-

land GmbH must be consulted beforehand.

The values determined here are necessary for planning the robot appli-

cation. For commissioning the robot, additional input data are required

in accordance with the operating and programming instructions of the

KUKA System Software.

The mass inertia must be verified using KUKA.Load or KUKA Compose.

It is imperative for the load data to be entered in the robot controller!

Fig. 4-6: KR 20 R3100, payload diagram

The KR 20 R3100 is designed for a rated payload of 20 kg in order to op-

timize the dynamic performance of the robot. The maximum payload of

23.6 kg applies only if the position of the center of mass is 0 mm and a

supplementary load optimized for the load case is mounted. The specific

load case must be verified using KUKA.Load or KUKA Compose. For fur-

ther consultation, please contact KUKA Support.

Mounting flange D=50

Robot wrist type ZH16/22

Mounting flange see drawing

Mounting flange (hole circle) 50 mm

Screw grade 12.9

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021 www.kuka.com | 41/344

Technical data

Loading...

Loading...