6-2 Printer Service Manual

5057-XXX

Lubrication specifications

Lubricate only when parts are replaced or as needed, not on a scheduled basis. Use of lubricants other than

those specified can cause premature failure. Some unauthorized lubricants may chemically attack

polycarbonate parts. Use IBM no. 10 oil, P/N 1280443 (Approved equivalents: Mobil DTE27, Shell Tellus 100,

Fuchs Renolin MR30), IBM no. 23 grease (Approved equivalent Shell Darina 1), and grease, P/N 99A0394 to

lubricate appropriate areas.

Scheduled maintenance

The LCD displays 80 scheduled maintenance at each 100K and 600K page count interval. It is necessary to

replace the appropriate maintenance kit at this interval to maintain the print quality and reliability of the printer.

The parts are available as a maintenance kit with the following part numbers:

40X4031—100K Maintenance Kit, 110 V

40X4093—100K Maintenance Kit, 220 V

40X4032—600K Maintenance Kit, 110 & 220 V

The ADF requires scheduled maintenance at each 150K page count interval. It is necessary to replace the feed/

pick roll assembly and the separation guide assembly at this interval to maintain ADF media feed reliability. The

parts are available as a maintenance kit with the following part number:

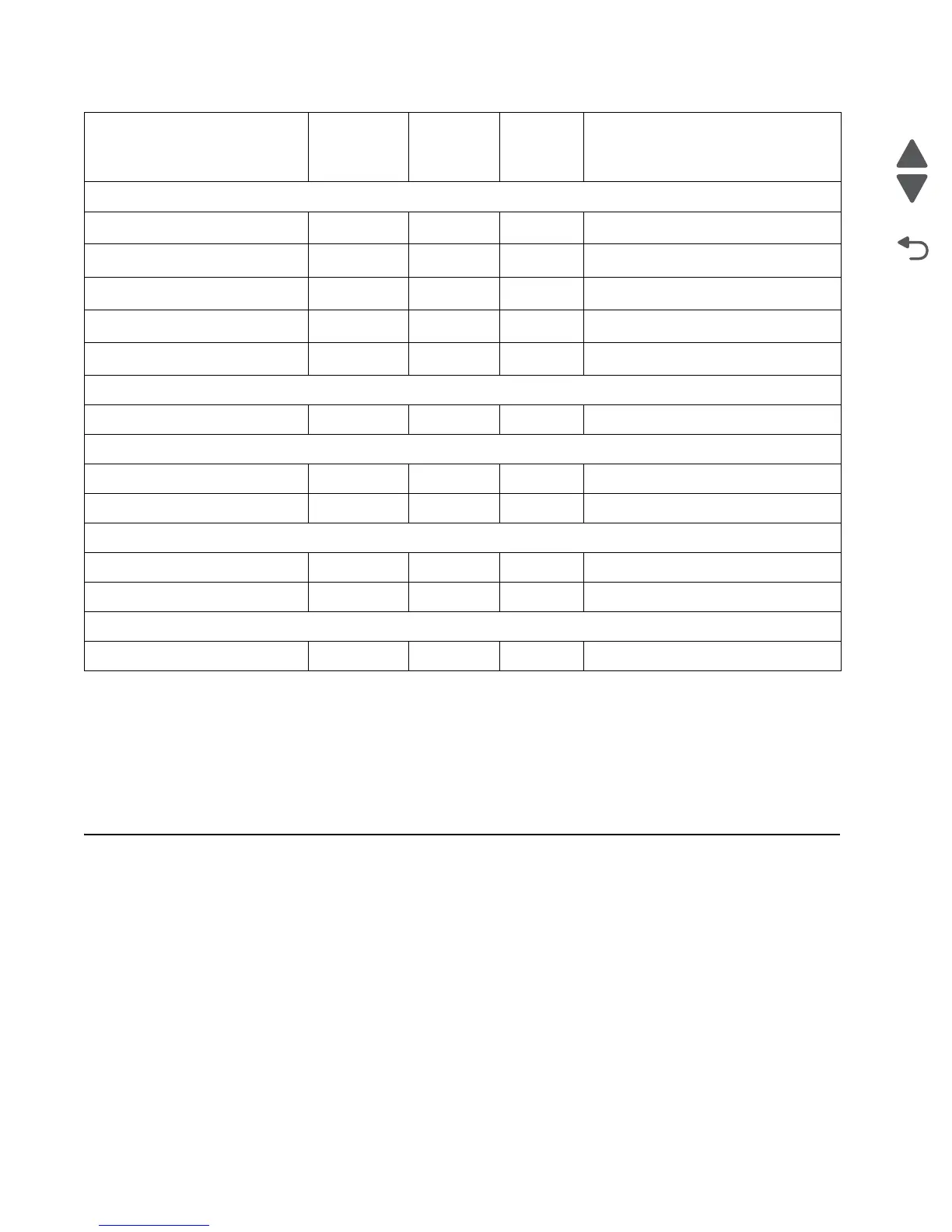

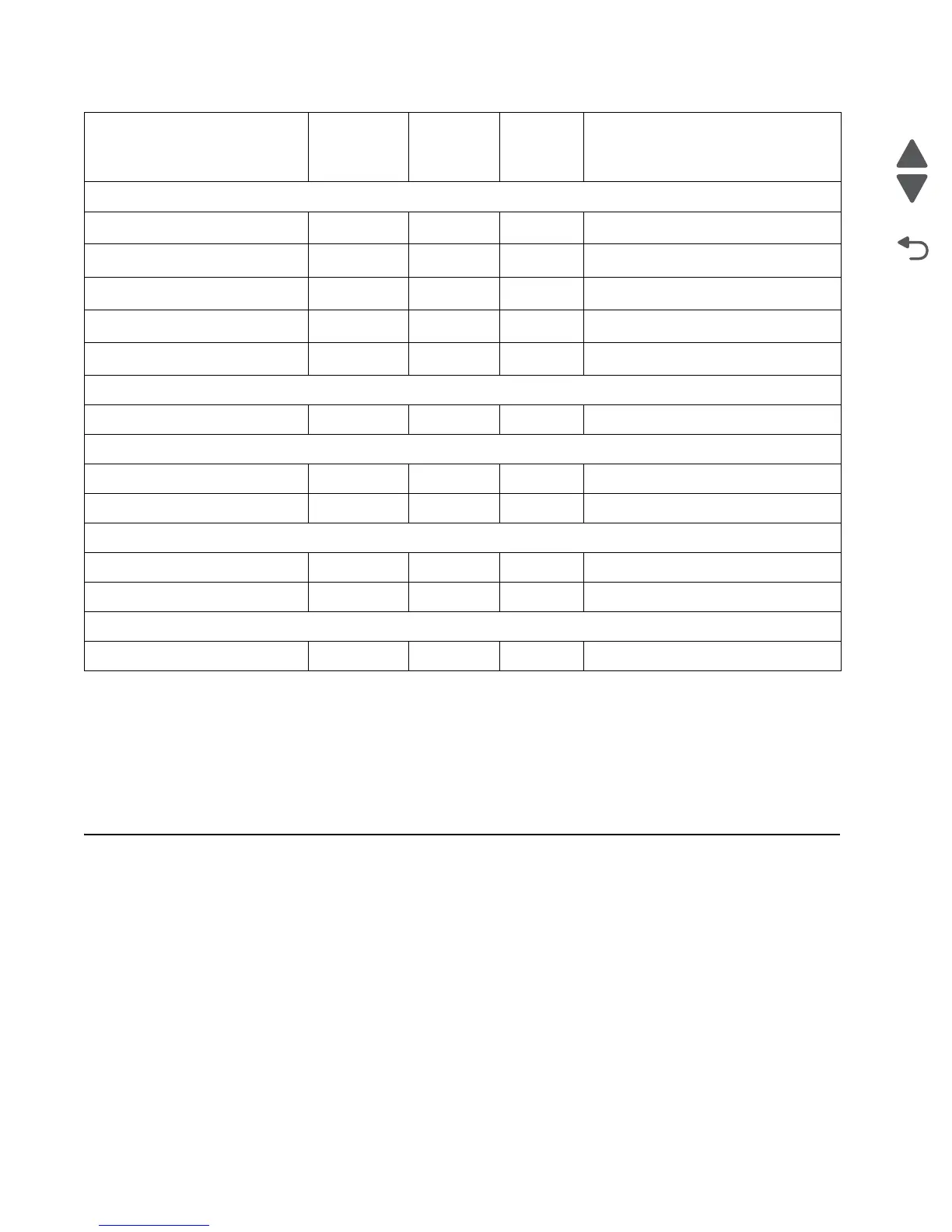

DEVELOPER UNITS Transfer

Developer unit (4) Replace

C developer carrier Replace

M developer carrier Replace

Y developer carrier Replace

K developer carrier Replace

TRANSFER ROLL

2nd Transfer Roll assembly Inspect Replace

TRANSFER BELT UNIT

Transfer belt unit assembly Inspect Replace Damp cloth

Transfer belt cleaning assembly Replace

FUSER UNIT

Fuser Unit Inspect Replace

Sensor (fuser exit) Clean Blower brush

DUPLEX

Duplex Media Transport Roll (2) Clean Water or alcohol

LEXMARK C935

EVERY

SERVICE

CALL

EVERY

100K

EVERY

600K

NOTE:

Loading...

Loading...