10) Dismantle the air discharging bolt of the rear disc brake gear.

11) Dismantle the piston of the rear brake slave cylinder.

Place a cloth or equivalent betw① een the slave cylinder and piston.

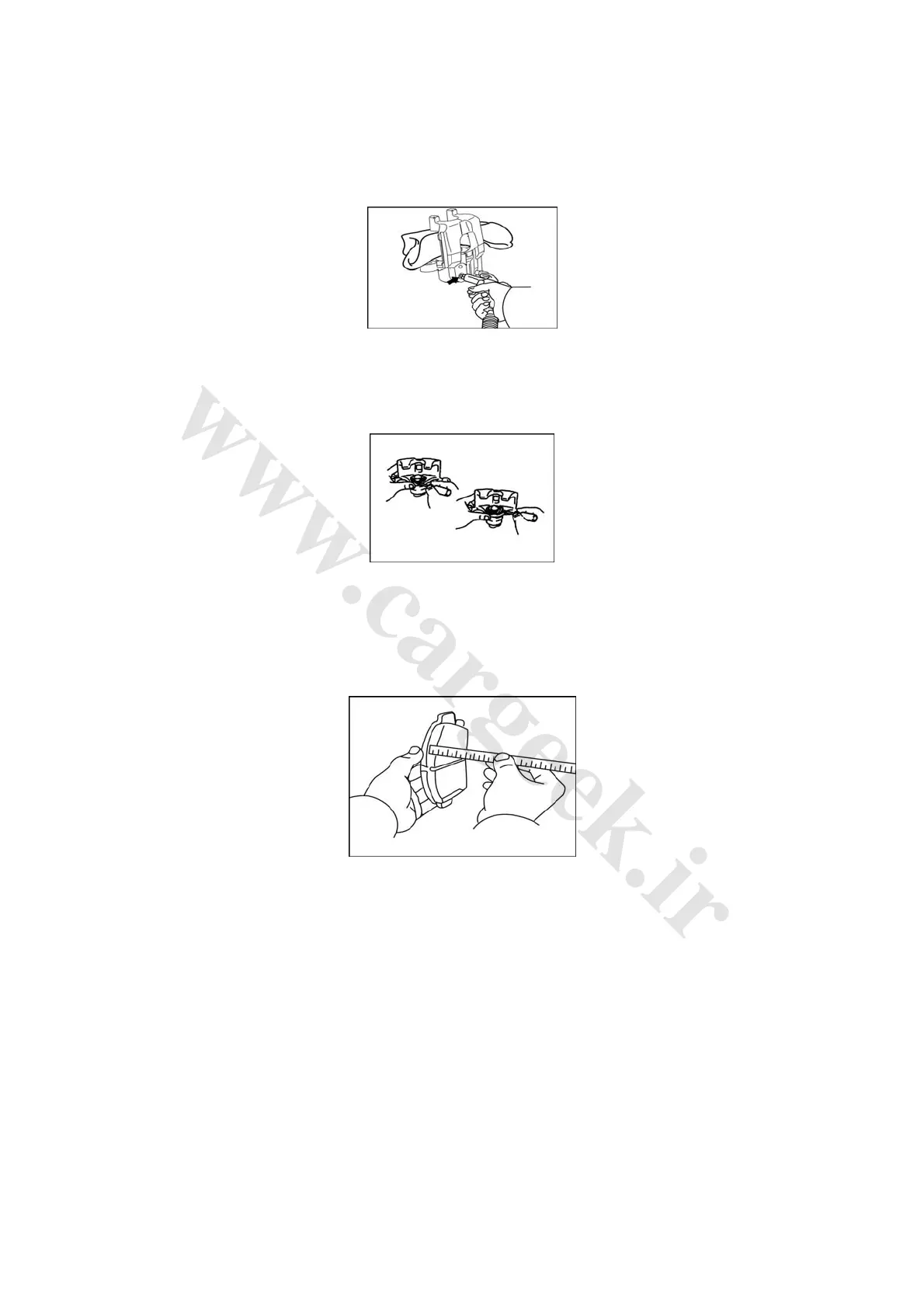

Blow out the piston from the brake slave cylinder by compressed air. See Fig. 2② -65.

Fig. 2-65

Note: Do not put your hand before the piston when blowing the compressed air. Do not splash the

brake fluid.

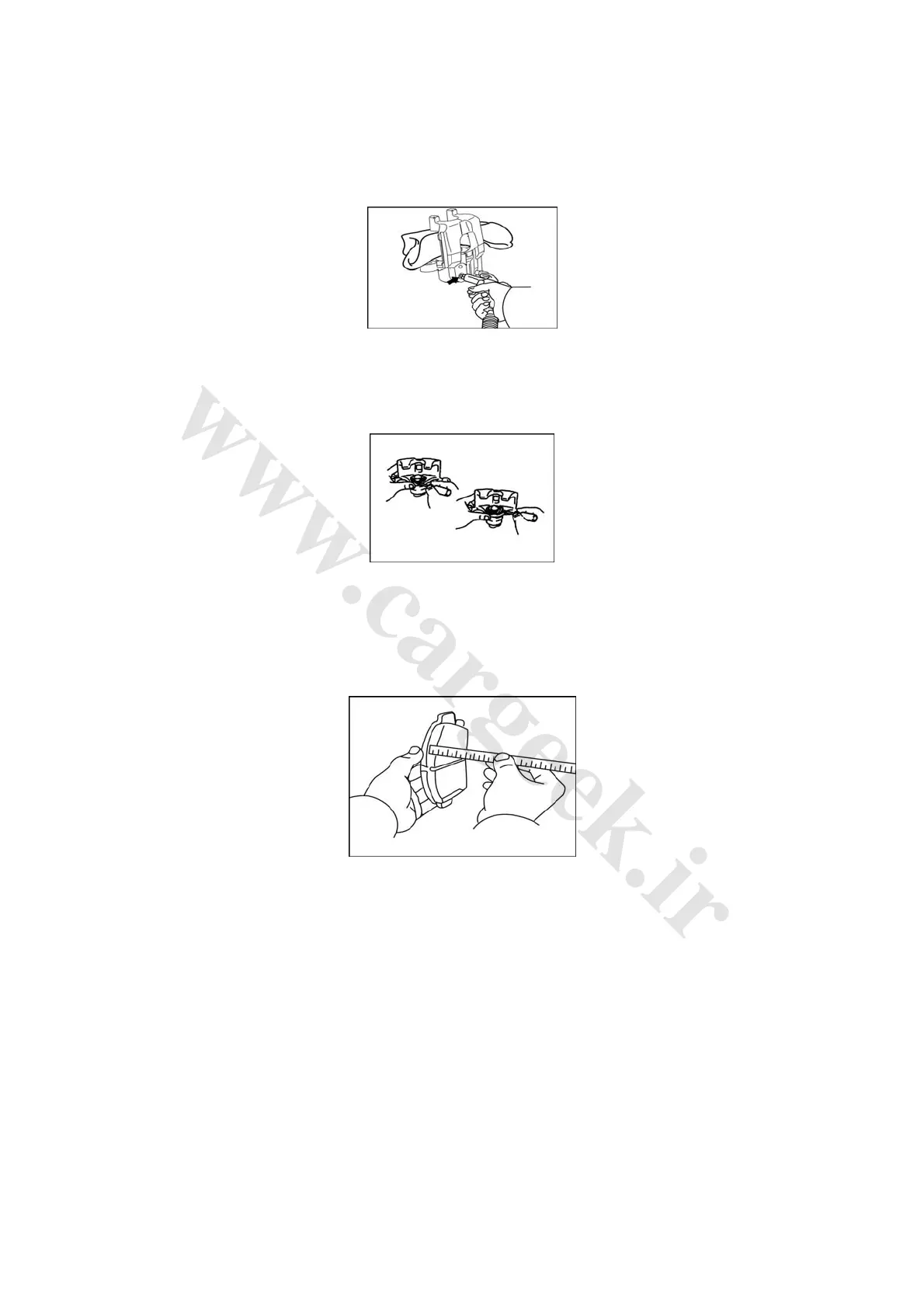

12) Remove the oil seal of piston. Take out the oil seal from the slave cylinder. See Fig. 2-66.

Fig. 2-66

(2) Inspection

1) Check the slave cylinder and piston. Check if the piston is rusty or scratched.

2) Check the thickness of the lining of brake pad. Measure the thickness by a ruler. See Fig. 2-67.

Standard: 10.0mm; min: 1.0mm.

Fig. 2-67

3) Check the sheet steel of the front brake wear indicator. Make sure that the sheet steel is enough

flexible and free of rust, dirt and other foreign material, and has no crack or wear.

4) Check the thickness of the brake disc. Measure the thickness of the brake disc by a micrometer

screw. Standard: 9.0mm; min: 8.0mm.

5) Take off the rear brake disc.

Mark on the brake disc and wheel hub.①

Take off the brake disc.②

6) Install brake disc. Note: Install it through the part with min thickness.

7) Check the brake disc swaying.

Temporarily tighten the brake disc. Tightening torque: 103N·m.①

Measure the swaying of brake disc at 10mm away from the outer edge of brake disc by a dia② l

indicator. See Fig. 2-68. Max: 0.05mm.

Loading...

Loading...