HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-22

Published 07-19-16, Control # 249-01

3. At the main relief valve (6) on the auxiliary system

control valve (5), loosen the lock nut and turn the

adjusting screw in one full turn. Securely tighten the lock

nut.

4. Start and run the engine at 1,500 rpm.

5. Fully retract both gantry cylinders until they bottom out

(stall the hydraulic system). Gauge pressure should be

241 to 248 bar (3,500 to 3,600 psi).

6. If the specified pressure is not indicated, proceed as

follows.

a. Loosen the lock nut on the adjusting screw for the

auxiliary system relief valve.

b. Turn the adjusting screw in to increase or out to

decrease the pressure.

c. Repeat step 5

through step 6b until the specified

pressure is obtained, and securely tighten the lock

nut.

7. Stop the engine and remove the gauge from the coupler

on the auxiliary system relief valve. Install a protective

cap over the coupler.

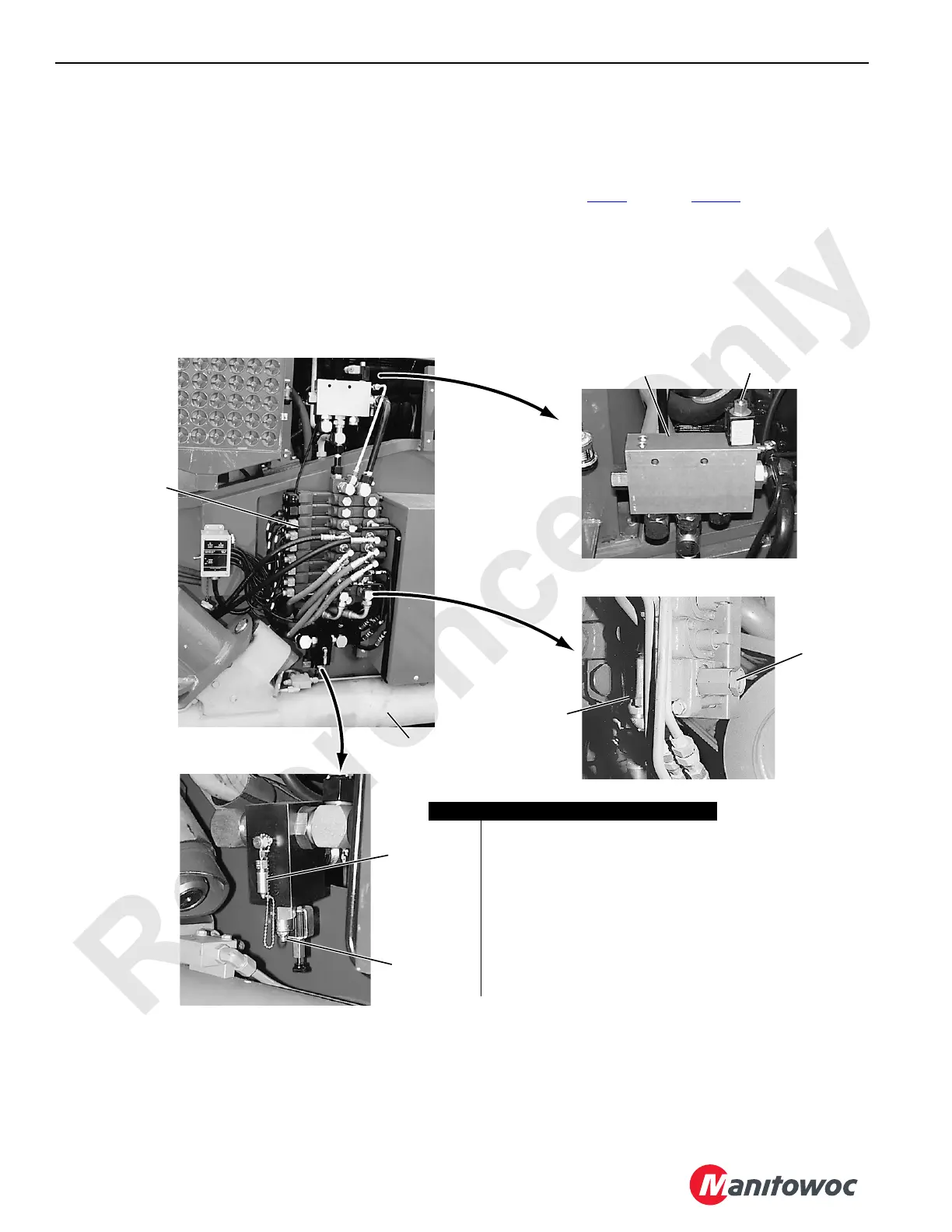

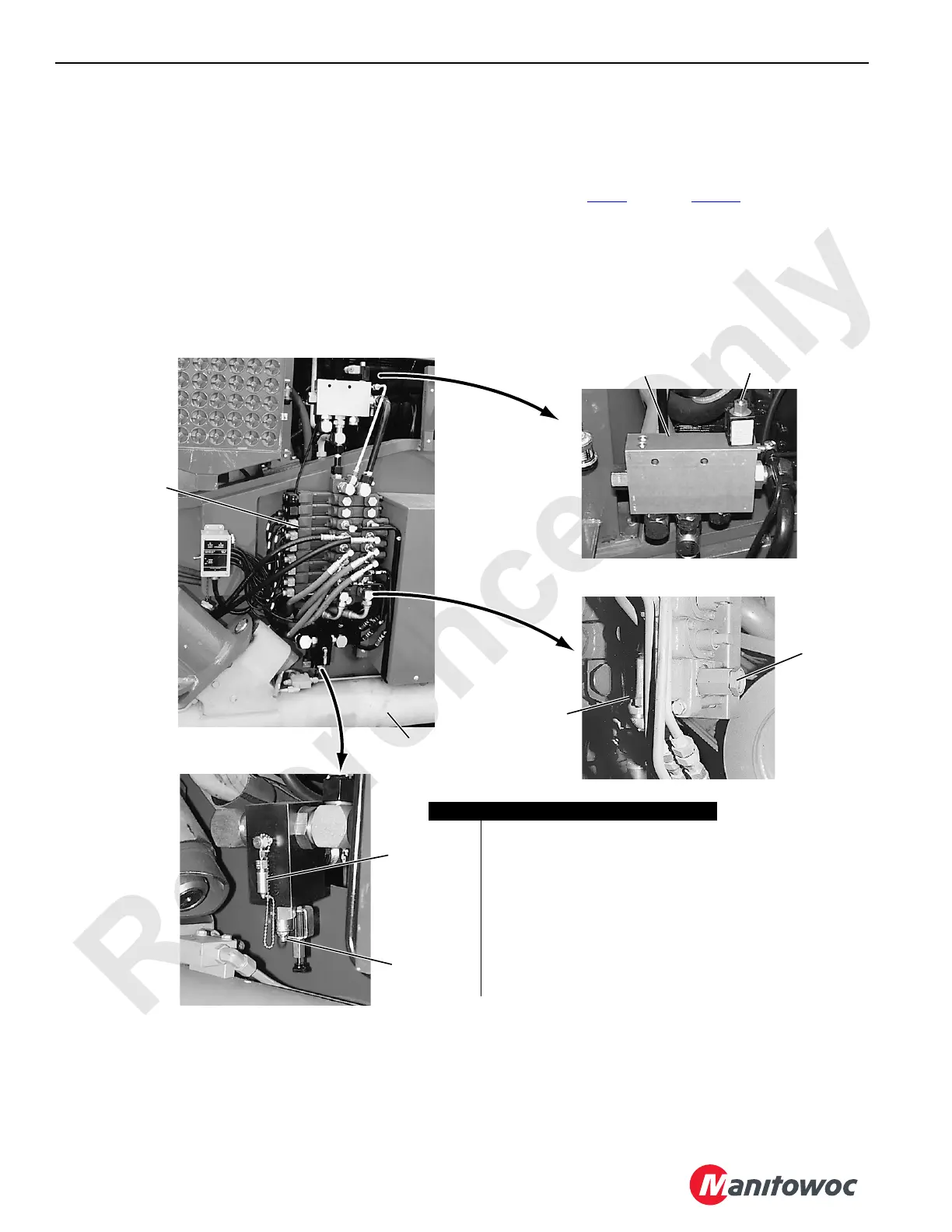

FIGURE 2-26

P923

P975

P922

P974

View C

View B

View A

Access at Right Rear

Corner of Rotating Bed

Item Description

1 Auxiliary System Valve Assembly

2 Jacking Cylinder (qty 4)

3 Proportional Flow Control Valve

4 Bleed Screw

5 Auxiliary System Control Valve

6 Main Relief Valve

(with lock nut and adjusting screw)

7 Gauge Coupler

8 Auxiliary System Relief Valve

(with lock nut and adjusting screw)

1

2

3

4

5

6

7

8

Loading...

Loading...