Manitowoc Published 07-19-16, Control # 249-01 5-29

2250 SERVICE/MAINTENANCE MANUAL HOISTS

Broken Wires

Thoroughly clean the wire rope so breaks can be seen.

Relax the rope, move it off pick-up points, and flex it as much

as possible. Use a sharp awl to pick and probe between

wires and strands, lifting any wire that appears loose or

moves excessively.

See Figure 5-26

for an explanation of lay length.

Wire rope must be taken out of service when it has the

following number of broken wires:

• Running ropes (working lines)—Six randomly distributed

broken wires in one lay length, or three broken wires in

one strand of one lay length

• Rotation resistant rope—Two randomly distributed

broken wires in a length equal to six rope diameters or

four randomly distributed broken wires in a length equal

to thirty rope diameters

• Standing ropes (pendants)—More than two broken

wires in one lay length in sections beyond the end

attachment, or more than one broken wire at the end

attachment (Figure 5-27

)

• All ropes—One broken wire at the point of contact with

the core that protrudes or loops out of the rope structure

United States Steel states, “Replacement criteria for

galvanized strand boom suspension pendants are 25

percent of the outer wires fractured, or 10 percent of the total

numbers, whichever comes first.”

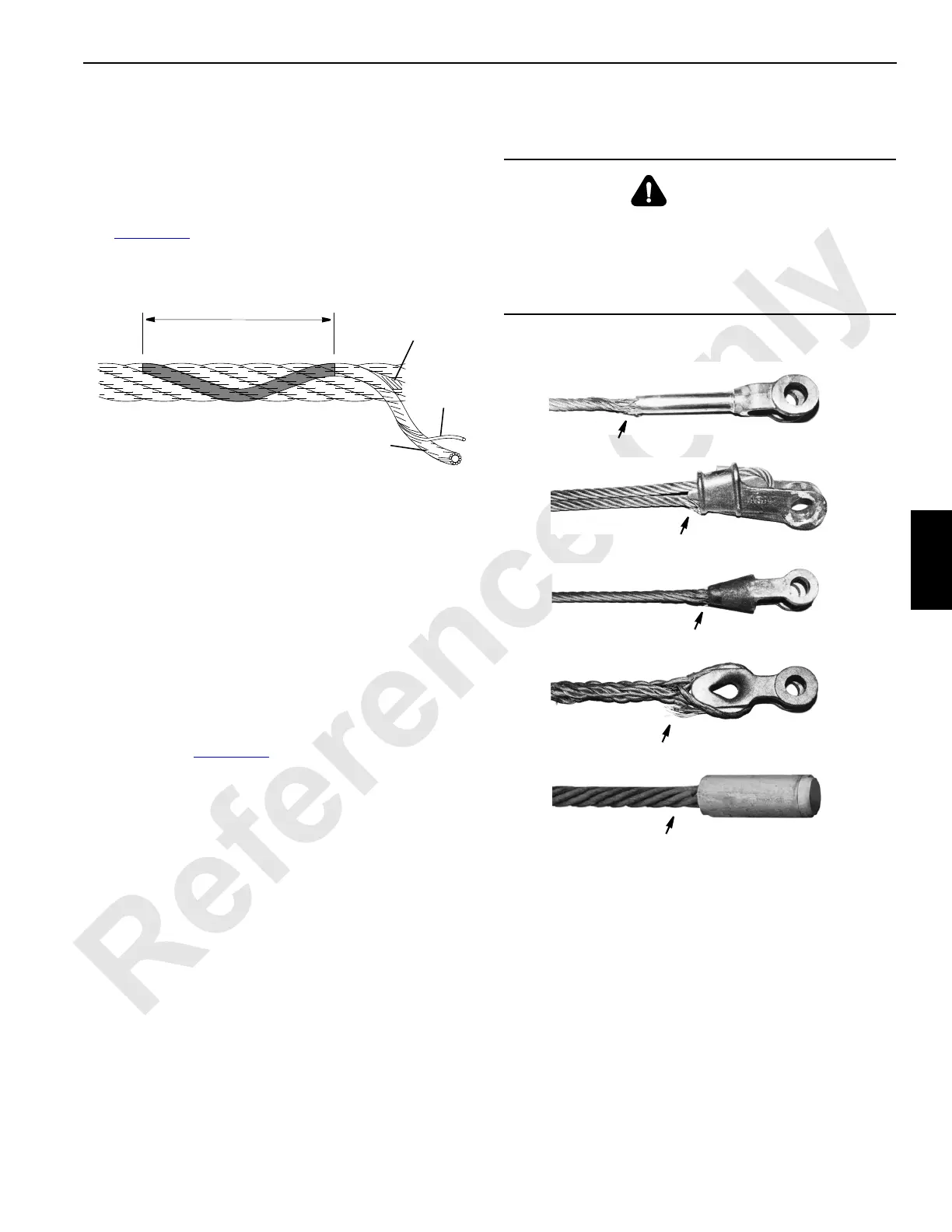

FIGURE 5-26

A925

Lay length is the distance measured along the rope in which

one strand makes one complete revolution around the core.

Core

One

Wire

One Strand

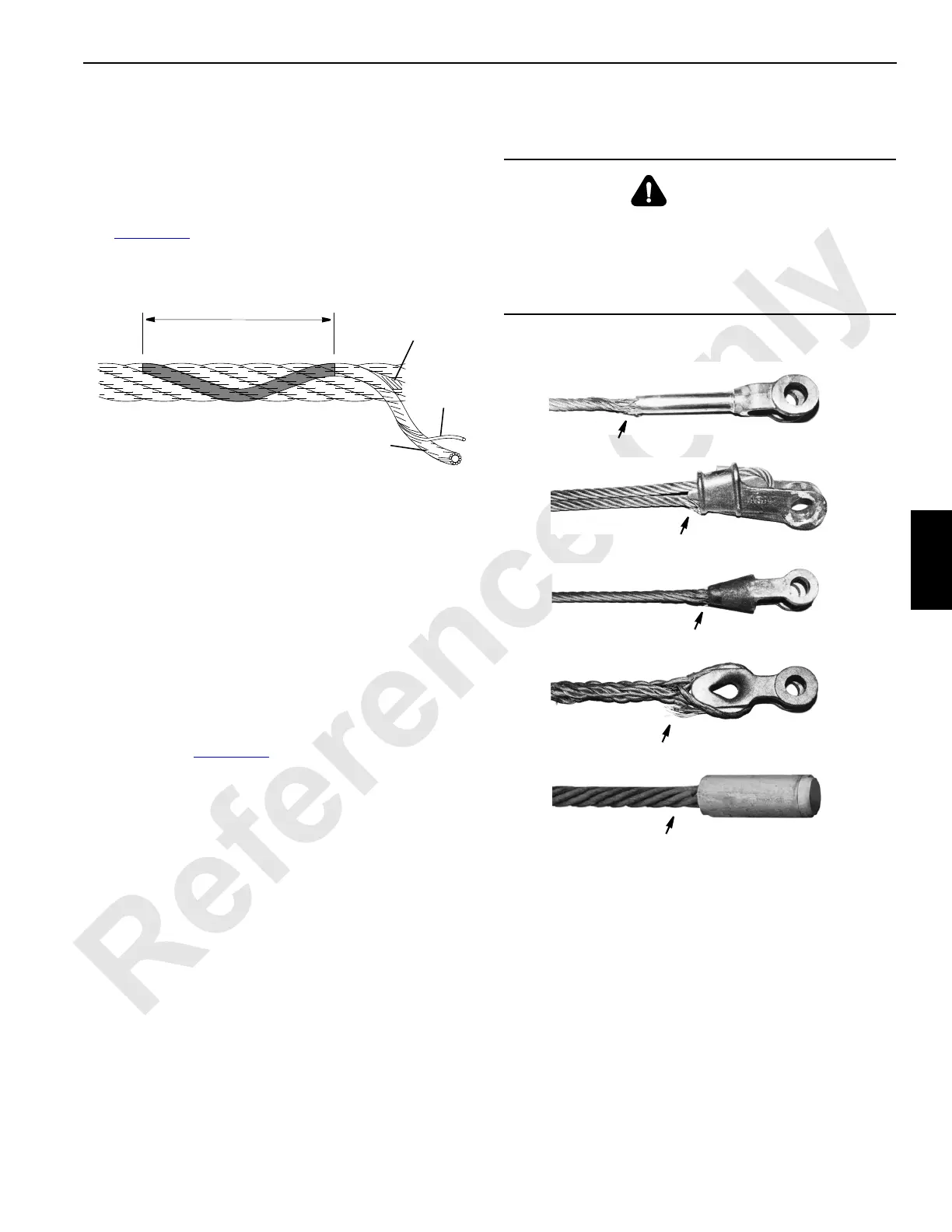

WARNING

Falling Load Hazard!

If wire rope is damaged, it can break, causing the load to

drop, thereby resulting in death or serious injury.

Replace the wire rope when more than one broken wire

appears at the points marked by the arrows.

FIGURE 5-27

S140

S142

S141

S143

S4412-144

Swage Socket

Wedge Socket

Poured Zinc Socket

Hand Splice

Button Socket

Loading...

Loading...