Manitowoc Published 07-19-16, Control # 249-01 1-25

2250 SERVICE/MAINTENANCE MANUAL INTRODUCTION

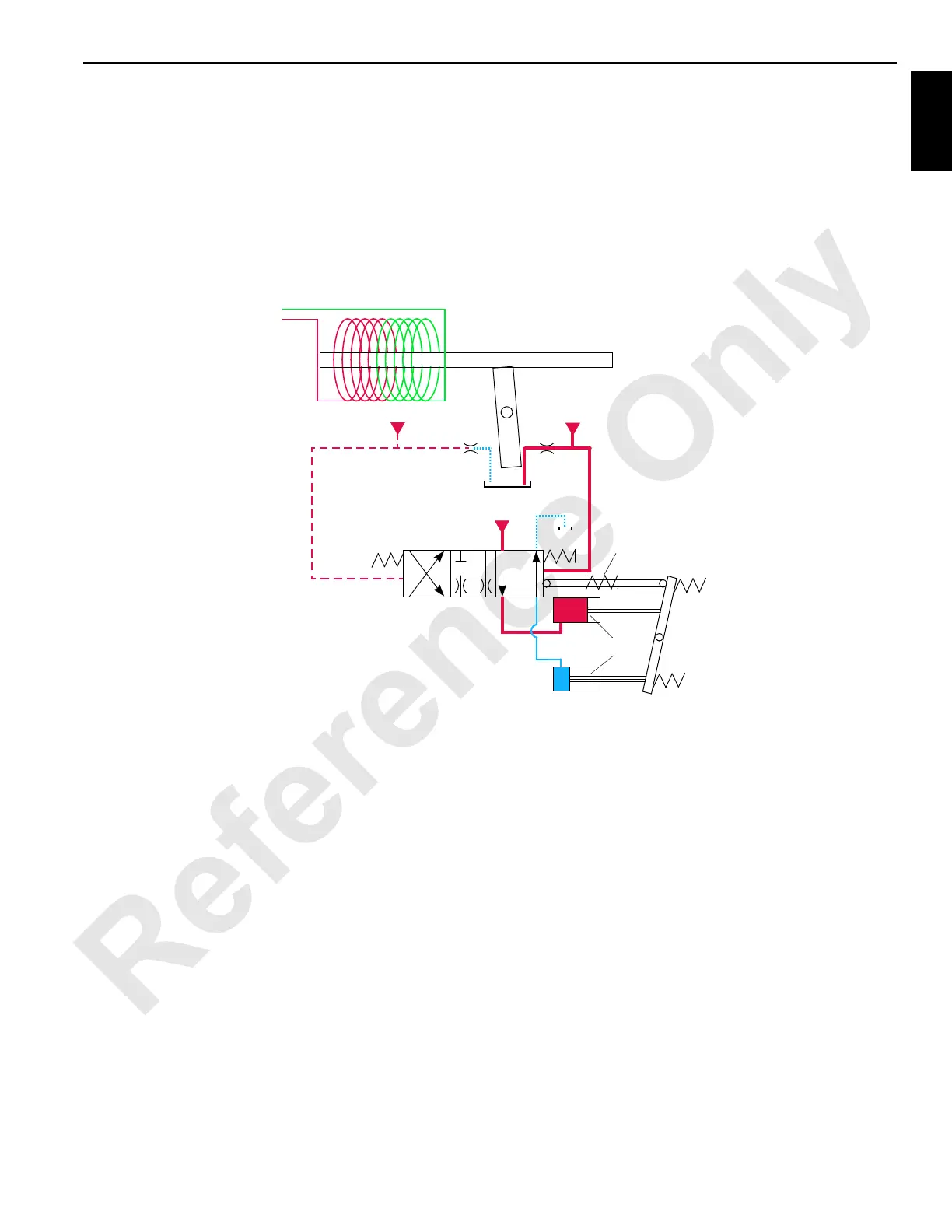

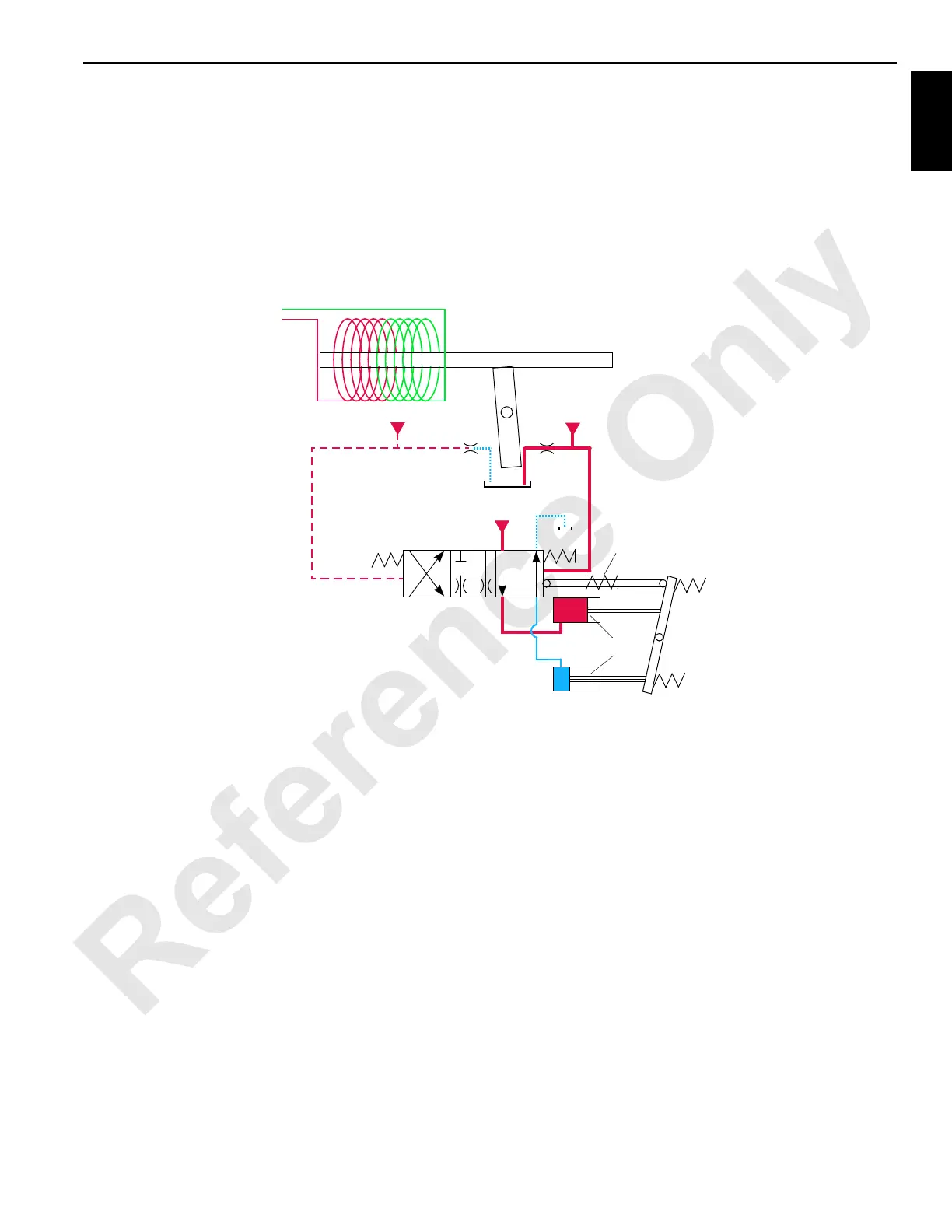

supplied pressure to perform the shifting operation. Servo

control fluid is supplied from the high-pressure line of motor

port A or B and shifts the shuttle valve and the servo control

valve before entering the servo cylinder.

Continuous changing of the closed-loop fluid occurs through

leakage in the pumps, motors, and loop-flushing valves.

Motor case fluid drainage lubricates the motor and provides

a recirculation of hydraulic fluid to control the heat in the

closed-loop system.

The loop-flushing (purge) system consists of a control valve

(17) and a relief valve (18). If the system pressure is above

14 bar (200 psi), the loop-flushing system removes 15 L/min

(4 gpm) of hot fluid from the system for added cooling. If

system pressure is under 14 bar (200 psi), the loop-flushing

system is disabled.

Swashplate

Servo Pistons

Pilot Pressure

Orifice

RF-02

Port

Modulation

Orifice

Port

Spring

Control Voltage

Armature

Spool

Pilot Pressure

Pilot Pressure

Spool

Spring

from Controller

FIGURE 1-10

Loading...

Loading...