Seite 44

Alterations reserved

Stand 05/2008

Operating manual T700/T800.1 - en

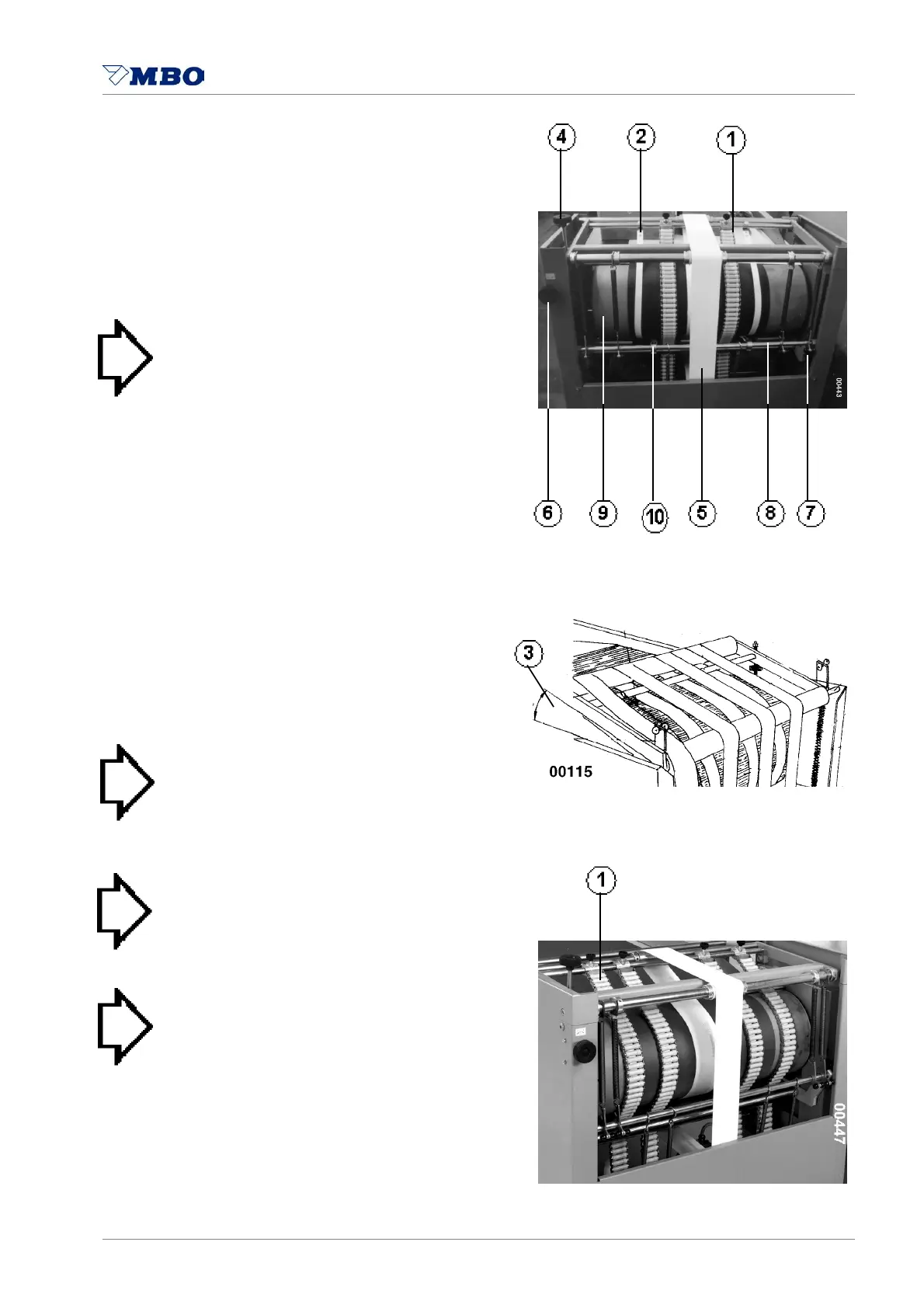

5.3.2 Drum

Set the roller chains 1 and

long Teflon tapes 2 in accordance

with the sheet size:

Distance of Teflon tapes 2 to the

paper edge should be approx. 2 cm;

mediate the roller chains 1.

Set the infeed angle between upper

table and roller chains 1 and

Teflon tapes 2 through the grip 4.

> NOTICE < The paper edges

may bend if the angle is too flat.

How to change the pressure of

tape 5 through knurled screw 6:

Clockwise turn, i.e. tape become loose,

counter-clockwise turn, i.e.tape become

stretched.

Pretension of springs 7

for the lower table 8.

Use one or two springs depending

on the sheet size and height of pile.

Please note that springs have different

sizes and latches.

Guide the sheet with medium pressure

around drum 9. Reduce the

pressure when you process very

smooth sheets and the shingle

at lower table 8 is increasing.

This will avoid backdraft of pile.

> NOTICE < Set the pretension

rather more light than too strong,

because the sheets may get sagged.

Use short Teflon tapes 10 at

the transition to the lower table 8.

> NOTICE < Never use Teflon tapes 2,

it will cause a braking effect!

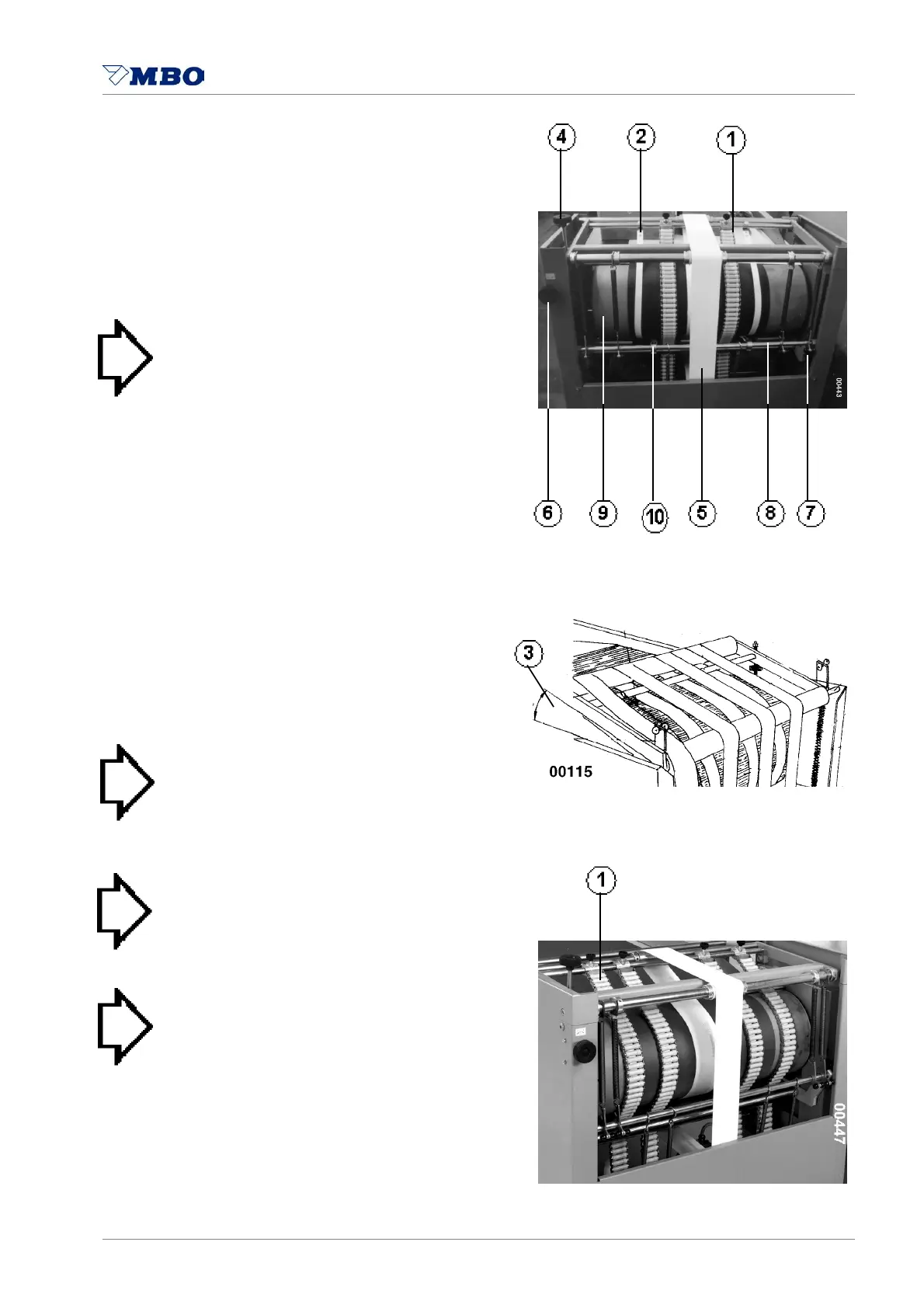

> NOTICE < The T 800 continuous

feeder is equipped with four

roller chains 1 around the rear drum.

Use only two roller chains if you

process a sheet width below 70 cm,

but four roller chains must be used

when you process a sheet width

above 70 cm. Therefore mediate

accordingly.

Loading...

Loading...