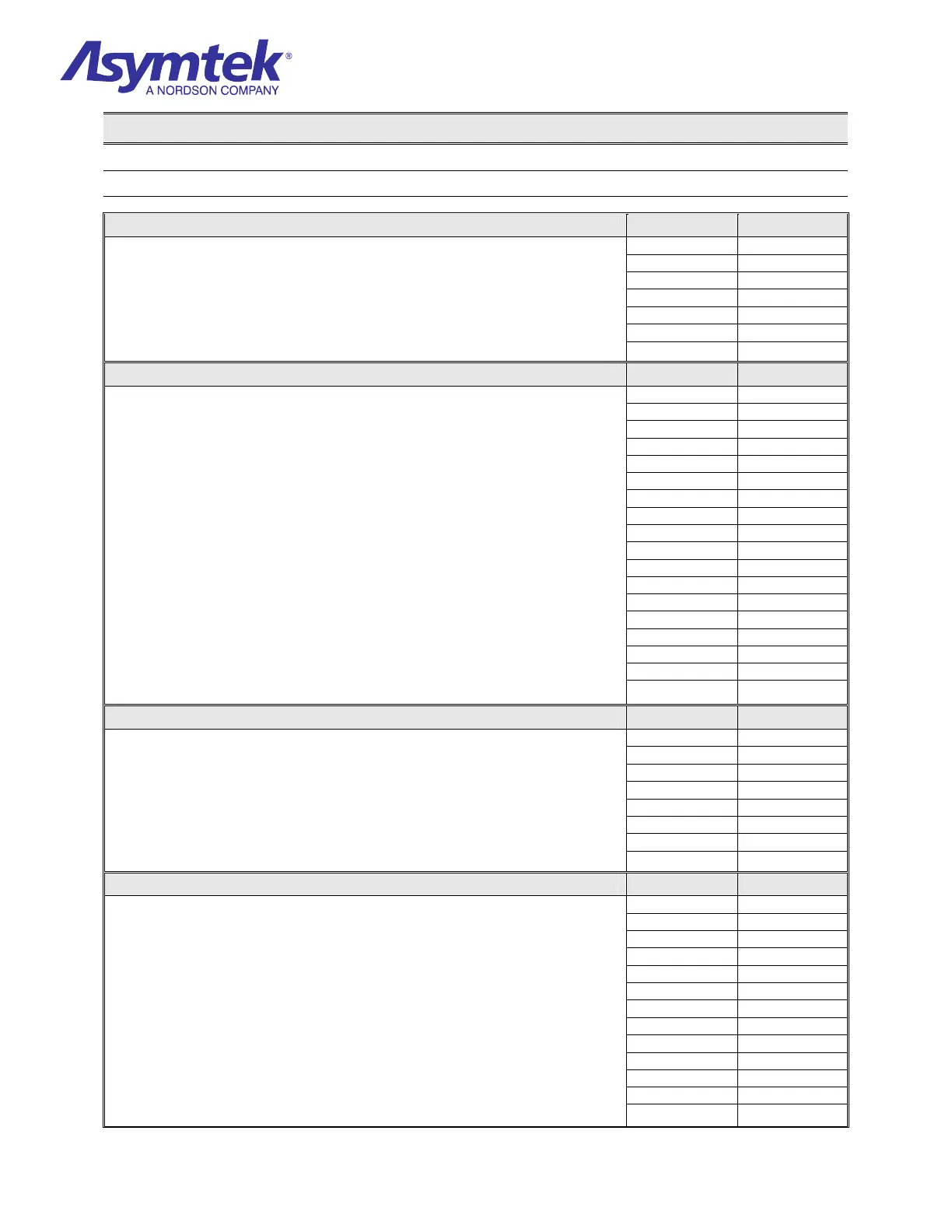

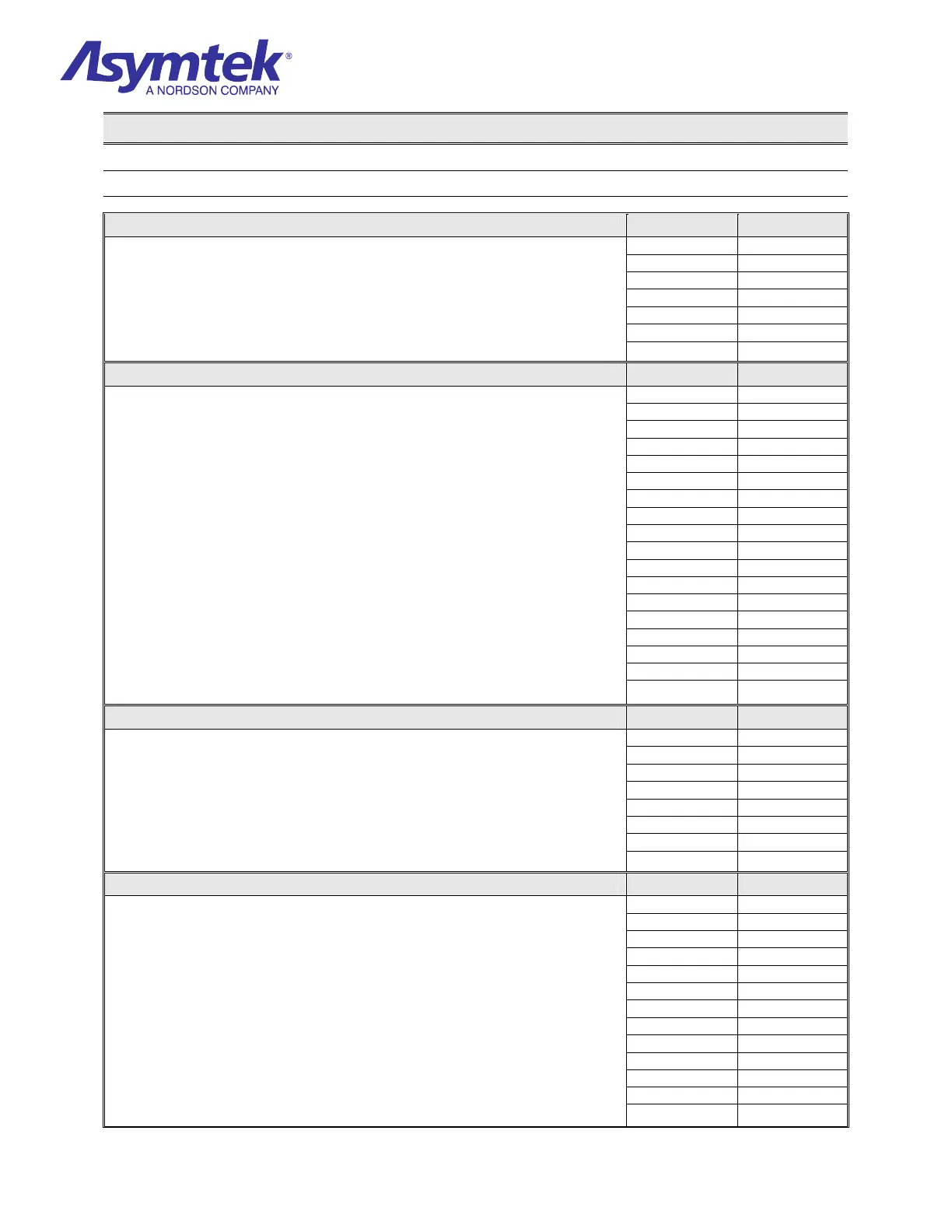

Level 2 Maintenance, X-1000 Series Dispensing Systems Course No. 196514

FINAL CERTIFICATION

STUDENT NAME: ID# INSTRUCTOR NAME:

FACTORY: DATE(S): TRAINING SITE:

MODULE 1 EQUIPMENT SAFETY INSTRUCTOR STUDENT

1.1 System Features

1.2 Safety Warning Labels

1.3 Startup/Shutdown Procedures

1.4 Emergency Shutdown Procedure

1.5 Safety Interlock and Light Pole/Beacon

1.6 Facility Requirements

1.7 Safety Precautions

MODULE 2 EQUIPMENT OPERATION INSTRUCTOR STUDENT

2.1 Theory of Operation

2.2 Dispensing System Components

2.3 Power Distribution

2.4 Pneumatic Distribution

2.5 Electrical and Pneumatic Paths

2.6 Vision System

2.7 Dispense Valves

2.8 Conveyor Operations

2.9 Dispensing Calibration Module

2.10 Linear Encoders

2.11 Height Sensor

2.12 Needle Sensor

2.13 Needle Heater

2.14 Part Heaters

2.15 Board Sensors

2.16 Stop Pins/Lift Tables/Bar Clamps

2.17 PMAC

2.18 PMAC Plot

MODULE 3 ROUTINE MAINTENANCE INSTRUCTOR STUDENT

3.1 Routine Maintenance Procedures

3.2 Purge Boot and Weigh Station Maintenance

3.3 Scale Leveling and Calibration

3.4 Draining the Water Trap

3.5 Lubricating the X-Beam and Y-Rail Linear Bearings

3.6 Lubricating and Tensioning the Positioner Cables

3.7 Cleaning and Replacing Conveyor Belts

3.8 Dispense Pump/Valve Maintenance

MODULE 4 TROUBLESHOOTING INSTRUCTOR STUDENT

4.1 Obtaining Asymtek Technical Support

4.2 Power Failure

4.3 Testing the I/O Functions of the Dispense and Conveyor

4.4 Troubleshooting XY-Axis Motion

4.5 Troubleshooting Z-Axis Motion

4.6 Troubleshooting the Servo Controller

4.7 Troubleshooting Pneumatics

4.8 Troubleshooting the Conveyor

4.9 Troubleshooting the Scale

4.10 Troubleshooting the Height Sensor

4.11 Troubleshooting the Tactile and Needle Sensors

4.12 Troubleshooting the Vision System

4.13 Troubleshooting Dispense Valves

-1000 SERIES

EVEL 2 MAINTENANCE TRAINING

Loading...

Loading...