Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 2-5 P/N 196515 (Revision A)

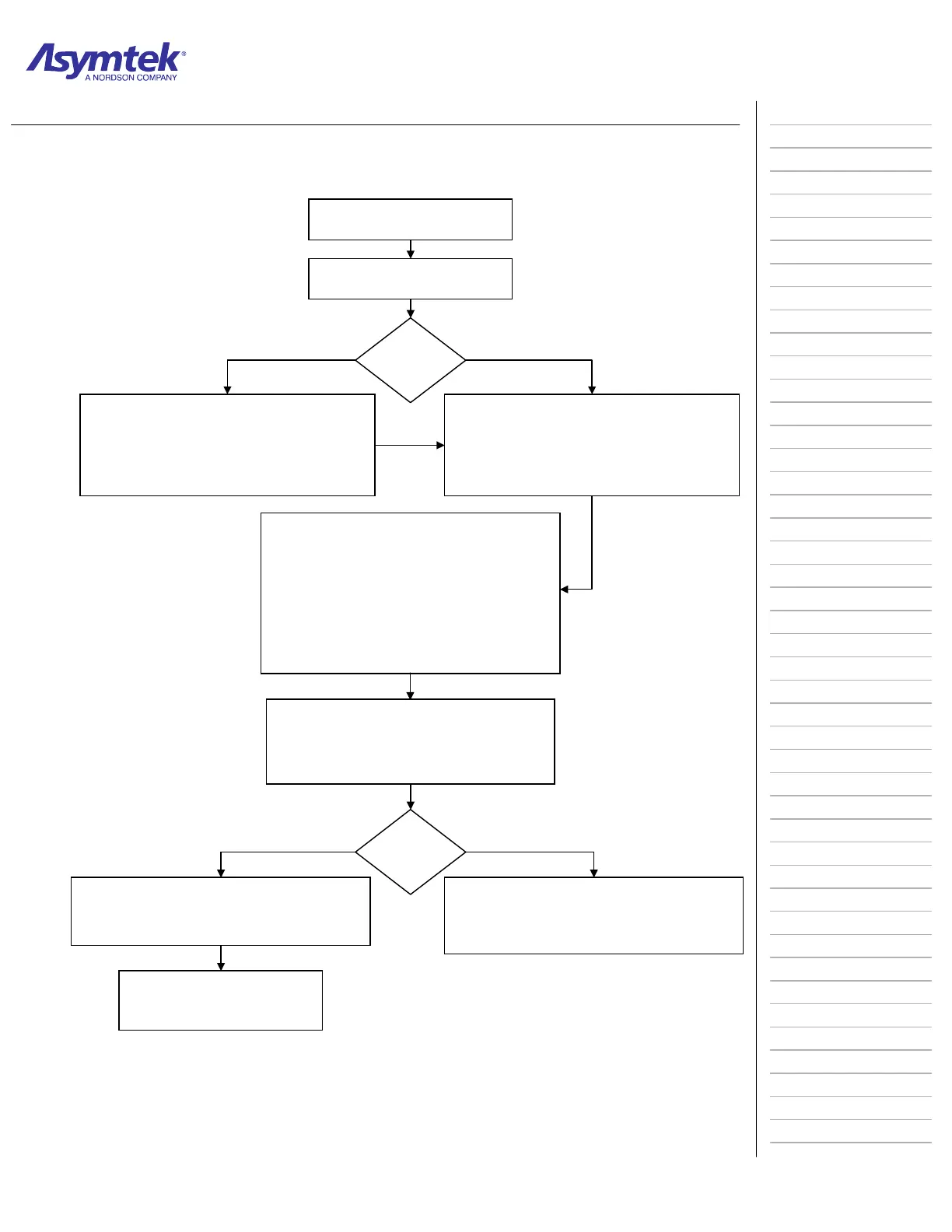

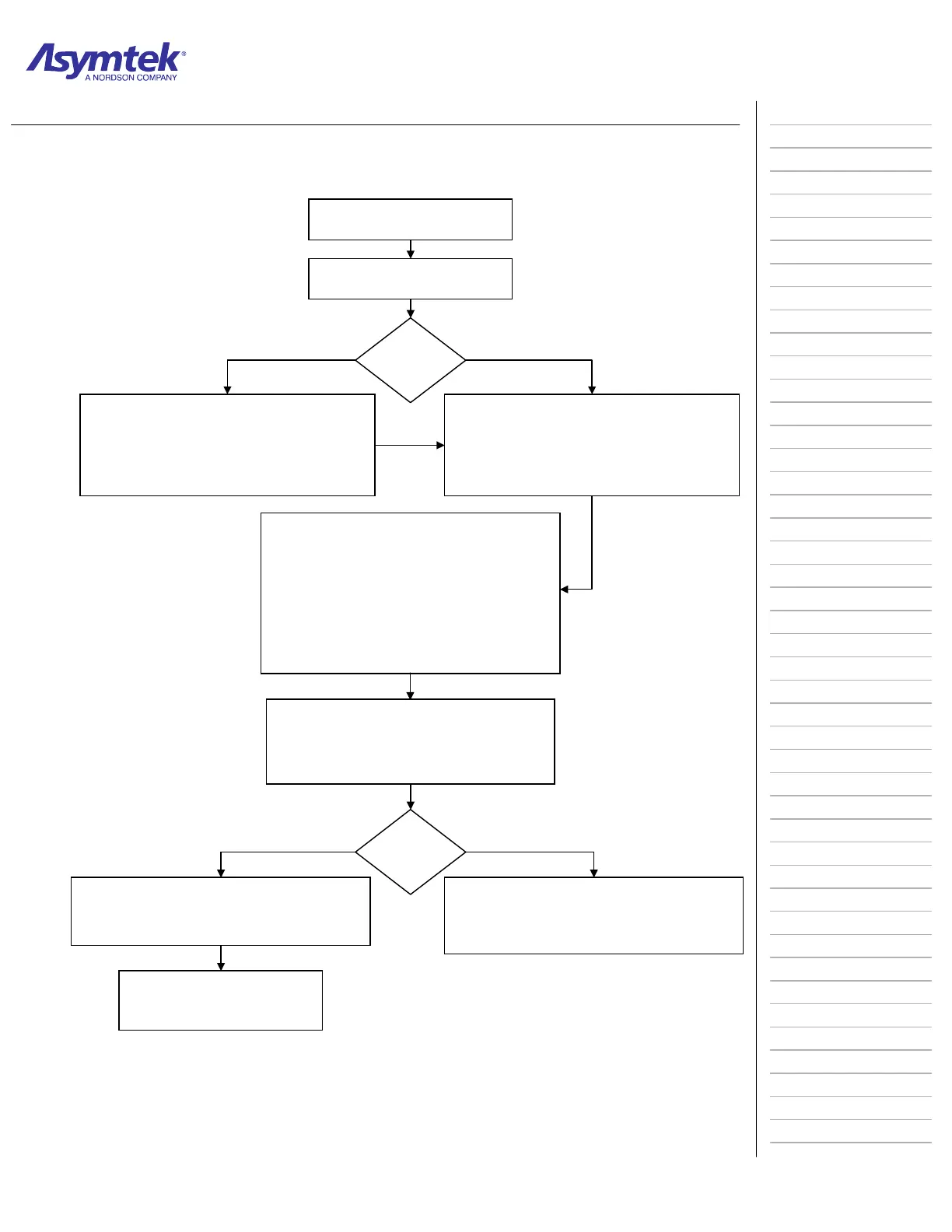

Diagram Sheet 2-1-1

Operations Flow Chart

A part enters the system from an upstream

location

Part is Conveyed to Pre-Dispense Zone

Stop Pins are lowered to stop part transport.

Clamp Bars or Lift Tables raise to hold the part in place.

The underboard heaters turn on and the part is heated to a pre-

programmed temperature. The part remains at the pre-dispense

station for a pre-programmed period of time.

Part is Conveyed to Dispense Zone

Stop Pins are lowered to stop part transport.

Lift Tables/Clamp Bars are raised to hold the part in place during

the dispensing process.

Another part is loaded into the Pre-dispense Station (optional).

A part sensor detects part and the part is

indexed

Dispensing Preparations are Performed

If required, the part is heated to a pre-programmed temperature

by Dispense Station underboard heaters.

The Dispense Head moves to the Purge Station and the

Dispense Valve purges.

If required, fluid may be heated by a Needle Heater (DV-7000 and

DP-3000 Valves) or a heater built into the Valve (DJ-2000).

The Vision System locates master fiducials on the part. Fiducials

are located as reference points for the dispensing patterns.

The Height Sensor probe is lowered to establish a Z-axis datum.

This

rovides information for settin

the dis

ense

a

in FmNT.

The pa

t is Conveyed into the Post-dispense Zone

Stop Pins are lowered to stop part transport.

Lift Tables/Clamp Bars are raised to hold the part in place.

Fluid is Dispensed

Fluid is dispensed onto the part according to a pre-

programmed dispensing pattern

When dispensing is complete, Stop Pins are raised, Lift

Tables/Clamp Bars are lowered.

Part is Conveyed to Downstream Machine or Unloade

The dispensing system can be programmed to move the part

directly to a downstream machine or onto an unloader.

Stop Pins and Clamp Bars or Lift Tables release the part and it is

conve

ed out of the s

stem

Part Exits System

• When dispensing is complete, Stop Pins

and Clamp Bars or Lift Tables release the

part and it is conveyed out of the system.

Pre-

Dispense

Zone?

Ye

No

Post-

Dispense

Zone?

Ye

No

Loading...

Loading...