Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-69 P/N 196515 (Revision A)

Information Sheet 4-6-2

Troubleshooting the Servo Controller (Continued)

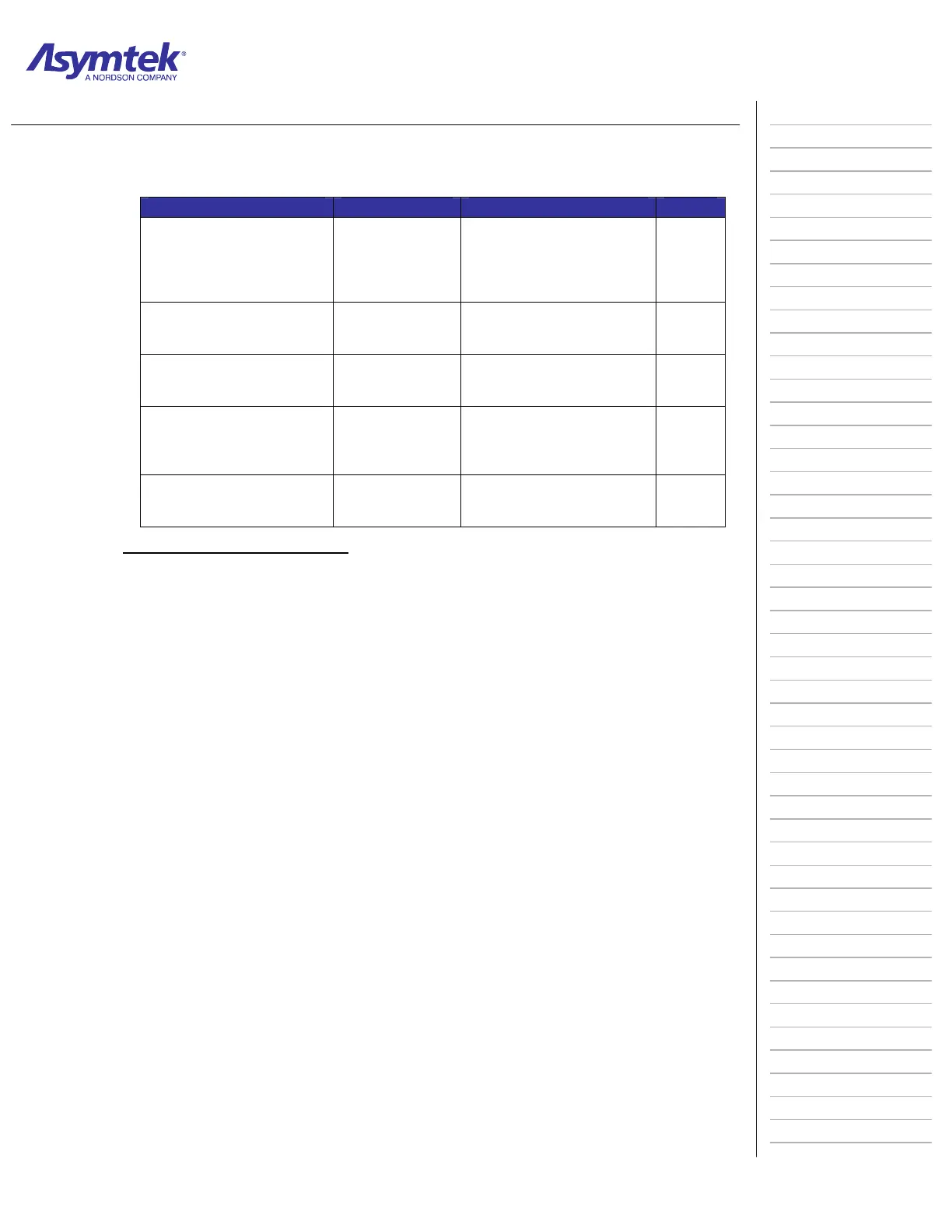

Symptom Probable Cause Fault Isolation Procedure Page

High vibration during X or Y-

axis movement

X or Y-axis

Rotary Encoder

“X-Axis Rotary Encoder

Verification” or “Y-Axis

Rotary Encoder Verification”

in PMAC Rotary Encoder

Fault Isolation

4-73

4-75

High vibration during Z-axis

movement

Z-axis Rotary

Encoder

“Z-Axis Rotary Encoder

Verification” in PMAC Rotary

Encoder Fault Isolation

4-77

Fast movement in X or Y-

axis with no vibration before

Dispensing Head stop

Linear Encoder

PMAC Linear Encoder Fault

Isolation

4-79

With power OFF, binding

and unusual noise when

manually moving the

Dispensing Head

Mechanical

System

PMAC Mechanical Fault

Isolation

4-84

Dispensing Head hits

mechanical hard stop during

homing process

Home Sensor

PMAC Home Sensor Fault

Isolation

4-86

C. Troubleshooting Guidelines

1. A dispensing system in need of troubleshooting may have High Voltage

present in both designated and unsuspected places that can result in injury

or death. It is imperative to adhere to Safety Precautions outlined in the

Safety Section of this training guide.

2. Disconnect and lockout power to systems connected to the dispensing

system (such as loaders and ovens) before troubleshooting. Failure to do so

may result in serious injury or death.

3. Troubleshooting should only be performed by an Asymtek Field Service

Engineer or an Asymtek-trained service technician.

4. Problems resulting from environmental and applications abnormalities, spills,

obstructions, and workpiece irregularities that are not system related should

be eliminated prior to undertaking more advanced troubleshooting.

5. To quickly identify problems, look for obvious signs such as burnt, discolored,

missing, damaged, or loose parts, obstructions, and foreign objects. Obvious

uncharacteristic odor, heat, noise, vibration, or movement can also be used

to quickly isolate problems. If a problem reoccurs frequently, there may be

other root causes to the problem.

6. Use proper Electrostatic Discharge precautions when handling the ESD

sensitive PMAC Card. Failure to do so, can result in irreversible damage to

the PMAC Card.

7. When Dispensing Head travel limits are not correct, the Dispensing Head can

hit hard stops causing potential hardware damage.

8. Use caution when reaching your hand into the dispensing chamber while

system is under power. Failure to take appropriate precautions could result in

injury or property damage

Loading...

Loading...