Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-84 P/N 196515 (Revision A)

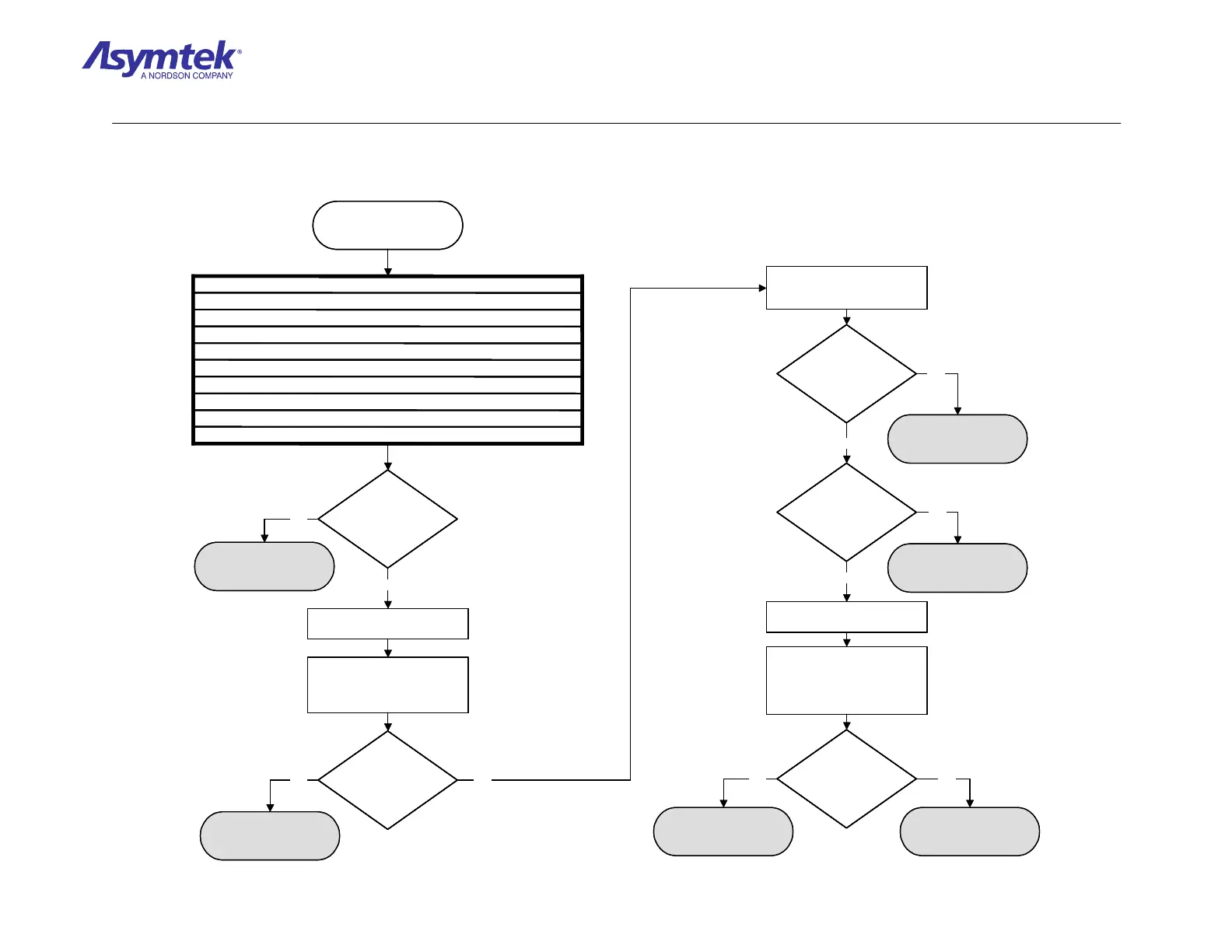

Inspect the Positioner

System for the following:

Is mechanical

correction required

as a result of

inspections?

Go to Servo Motor

Verification

Go to PMAC Linear

Encoder Fault Isolation

Procedure

• No play in the X and Y-axis Linear Bearings.

• Damaged, dirty, or ungreased Linear Bearing Guides and Bearings.

• Damage such as cracking or cuts to plastic sleeves on Cables.

• Dirty or ungreased X and Y-axis Motor Cables.

• Binding of X or Y Servo Motor Drum Cables.

• Loose X or Y Servo Motor Drum Cables.

• Cables that have slipped off the pulleys.

• Cables not properly routed.

• Disconnected segments, binding, or loose mounting brackets in the Cat Track.

• Obstructions that might contact the Dispensing Head in the suspected area.

Press the black OFF (0) button

on the Operator’s Console.

Open the Front Hatch and

manually move the Dispensing

Head throughout the dispensing

chamber in X or Y, and Z-axis.

Are movements

smooth and linear with

no binding or unusual

noise?

Yes

Press the green ON (I) button on

the Operator’s Console and

open FmNT.

Does Dispensing

Head complete the

homing process with no

FmNT messages.

Can Dispensing

Head be moved in X and

Y axes with Jog keys

[Ctrl+Shift+Arrow keys]

on keyboard?

From the FmNT Main Menu,

click on the Jog icon.

In the Jog Window, point and

click at several locations in the

blue square to move the

Dispensing Head throughout the

dispensing chamber.

Did

FmNT message

“30735 Motor has gone

open loop? Press OK to

continue and reinitialize

motion controller”

appear?

Go to PMAC Initialization

Fault Isolation Procedure

Stop! A mechanical issue

is the root cause of the

fatal following error.

Yes No

Yes

Go to PMAC Fatal Following

Error Verification in PMAC

Initialization Fault Isolation

Procedure

Go to PMAC Initialization

Fault Isolation Procedure

No

No Yes

Yes

No

No

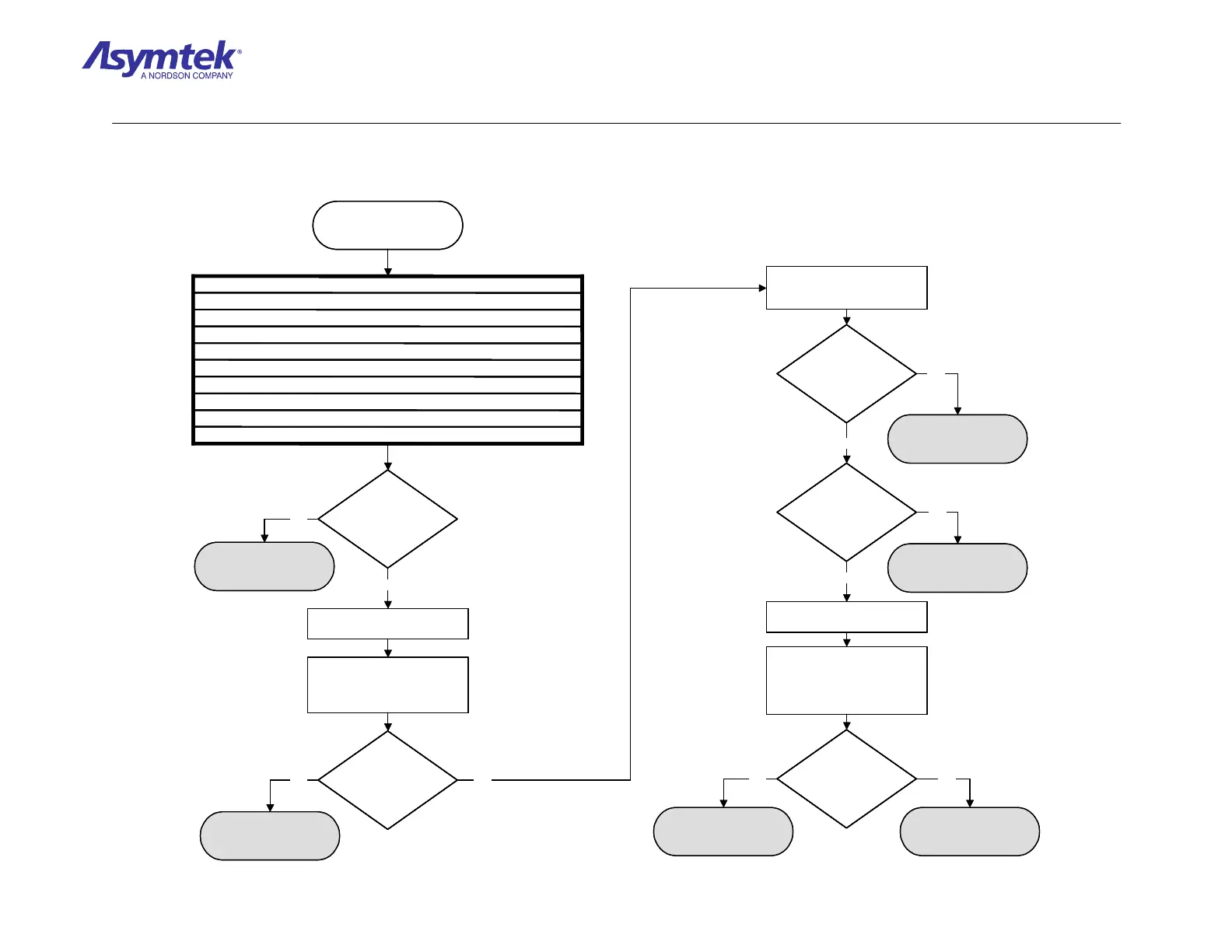

Inspect the Positioner

System for the following:

Is mechanical

correction required

as a result of

inspections?

Is mechanical

correction required

as a result of

inspections?

Go to Servo Motor

Verification

Go to PMAC Linear

Encoder Fault Isolation

Procedure

• No play in the X and Y-axis Linear Bearings.

• Damaged, dirty, or ungreased Linear Bearing Guides and Bearings.

• Damage such as cracking or cuts to plastic sleeves on Cables.

• Dirty or ungreased X and Y-axis Motor Cables.

• Binding of X or Y Servo Motor Drum Cables.

• Loose X or Y Servo Motor Drum Cables.

• Cables that have slipped off the pulleys.

• Cables not properly routed.

• Disconnected segments, binding, or loose mounting brackets in the Cat Track.

• Obstructions that might contact the Dispensing Head in the suspected area.

• No play in the X and Y-axis Linear Bearings.

• Damaged, dirty, or ungreased Linear Bearing Guides and Bearings.

• Damage such as cracking or cuts to plastic sleeves on Cables.

• Dirty or ungreased X and Y-axis Motor Cables.

• Binding of X or Y Servo Motor Drum Cables.

• Loose X or Y Servo Motor Drum Cables.

• Cables that have slipped off the pulleys.

• Cables not properly routed.

• Disconnected segments, binding, or loose mounting brackets in the Cat Track.

• Obstructions that might contact the Dispensing Head in the suspected area.

Press the black OFF (0) button

on the Operator’s Console.

Open the Front Hatch and

manually move the Dispensing

Head throughout the dispensing

chamber in X or Y, and Z-axis.

Are movements

smooth and linear with

no binding or unusual

noise?

Are movements

smooth and linear with

no binding or unusual

noise?

Yes

Press the green ON (I) button on

the Operator’s Console and

open FmNT.

Does Dispensing

Head complete the

homing process with no

FmNT messages.

Does Dispensing

Head complete the

homing process with no

FmNT messages.

Can Dispensing

Head be moved in X and

Y axes with Jog keys

[Ctrl+Shift+Arrow keys]

on keyboard?

Can Dispensing

Head be moved in X and

Y axes with Jog keys

[Ctrl+Shift+Arrow keys]

on keyboard?

From the FmNT Main Menu,

click on the Jog icon.

In the Jog Window, point and

click at several locations in the

blue square to move the

Dispensing Head throughout the

dispensing chamber.

Did

FmNT message

“30735 Motor has gone

open loop? Press OK to

continue and reinitialize

motion controller”

appear?

Did

FmNT message

“30735 Motor has gone

open loop? Press OK to

continue and reinitialize

motion controller”

appear?

Go to PMAC Initialization

Fault Isolation Procedure

Stop! A mechanical issue

is the root cause of the

fatal following error.

Yes No

Yes

Go to PMAC Fatal Following

Error Verification in PMAC

Initialization Fault Isolation

Procedure

Go to PMAC Initialization

Fault Isolation Procedure

No

No Yes

Yes

No

No

Diagram Sheet 4-6-15

PMAC Mechanical Fault Isolation Procedure – X and Y-Axis Mechanical Verification

Loading...

Loading...