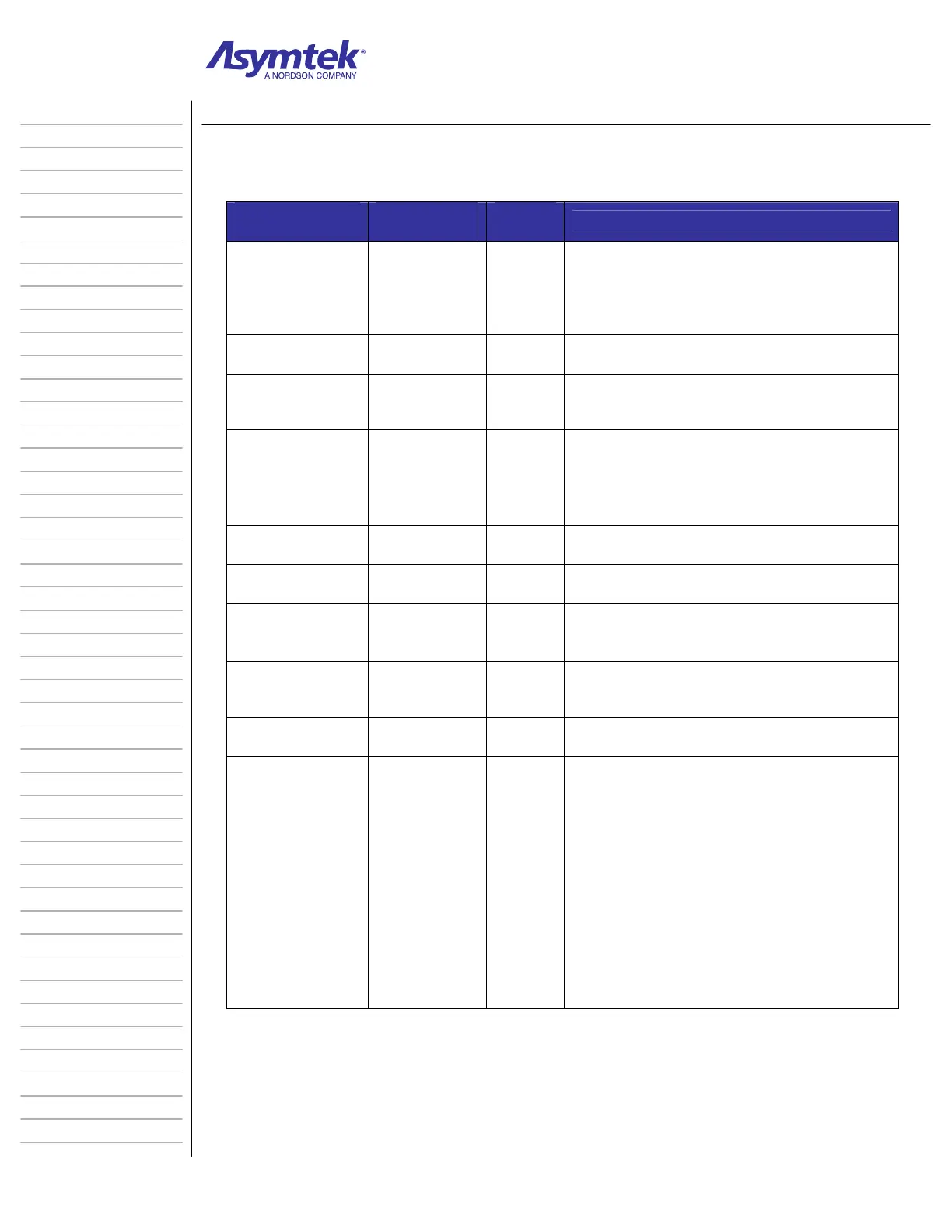

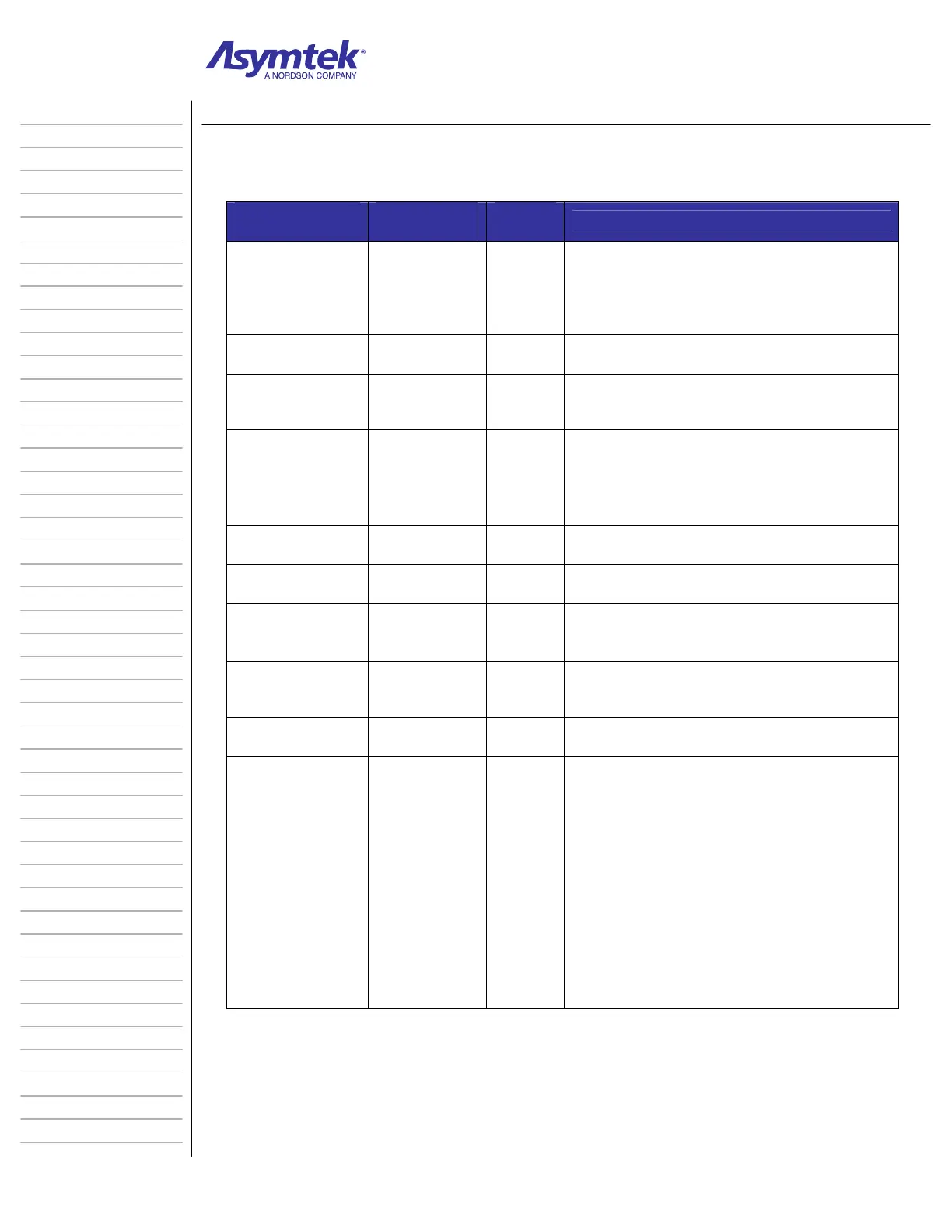

Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 3-2 P/N 196515 (Revision A)

Information Sheet 3-1-1

Routine Maintenance Procedure Schedule

Maintenance

Procedure

Recommended

Frequency

Est.

Time

Instructions

Clean Purge

Station boot.

Daily 3 minutes

1. Remove the Purge Station cover.

2. Clean the boot and cover with a small

bottlebrush and the solvent recommended by

the fluid manufacturer (see MSDS).

3. Replace Purge Station cover.

Replace Purge

Station cup.

Daily 3 minutes

See Exercise Sheet 3-2-1 on page 3-6.

Replace Weigh

Station cup and

banjo wiper.

Daily 3 minutes

See Exercise Sheet 3-2-1 on page 3-6.

Clean fluid on

miscellaneous

surfaces.

Daily 5 minutes

• For damp spills, wipe with a clean, dry, soft

cloth.

• For dried spills, clean with the manufacturer

MSDS recommended solvent and a clean, soft

cloth.

Clean Dispensing

Valve.

Daily

30

minutes

See Lesson 3-8 on page 3-39.

Drain Water Trap. Weekly

20

minutes

See Exercise Sheet 3-4-1 on page 3-20.

Tension the

Positioner Cables.

Weekly

90

minutes

Average frequency. It will vary with your

application.

See Exercise Sheet 3-6-2 on page 3-30.

Clean Hatch

window and Monitor

Screen

Weekly 3 minutes

Use ammonia-based window cleaner or isopropyl

alcohol (IPA) and a clean, soft cloth.

Replace Purge

Station boot.

Every 2 weeks 5 minutes

See Exercise Sheet 3-2-2 on page 3-8.

Clean dispensing

system chassis.

Every 2 weeks 5 minutes

Use isopropyl alcohol (IPA) and a clean, soft cloth

to wipe down the top, sides and front of the

dispensing system. Make sure that you remove all

residual fluid and dirt.

Clean Conveyor

belts and rails.

Every 2 weeks

30

minutes

1. Clear the Conveyor of all boards or carriers.

2. Open the Hatch and manually move the

Dispensing Head to the back of the dispensing

area.

3. Using isopropyl alcohol and a soft cloth, wipe

the length of each Conveyor belt.

4. Using MSDS-recommended solvent and a soft

cloth, clean any wet or dry fluid that may have

spilled on the Conveyor rails.

5. Close the Hatch.

Loading...

Loading...