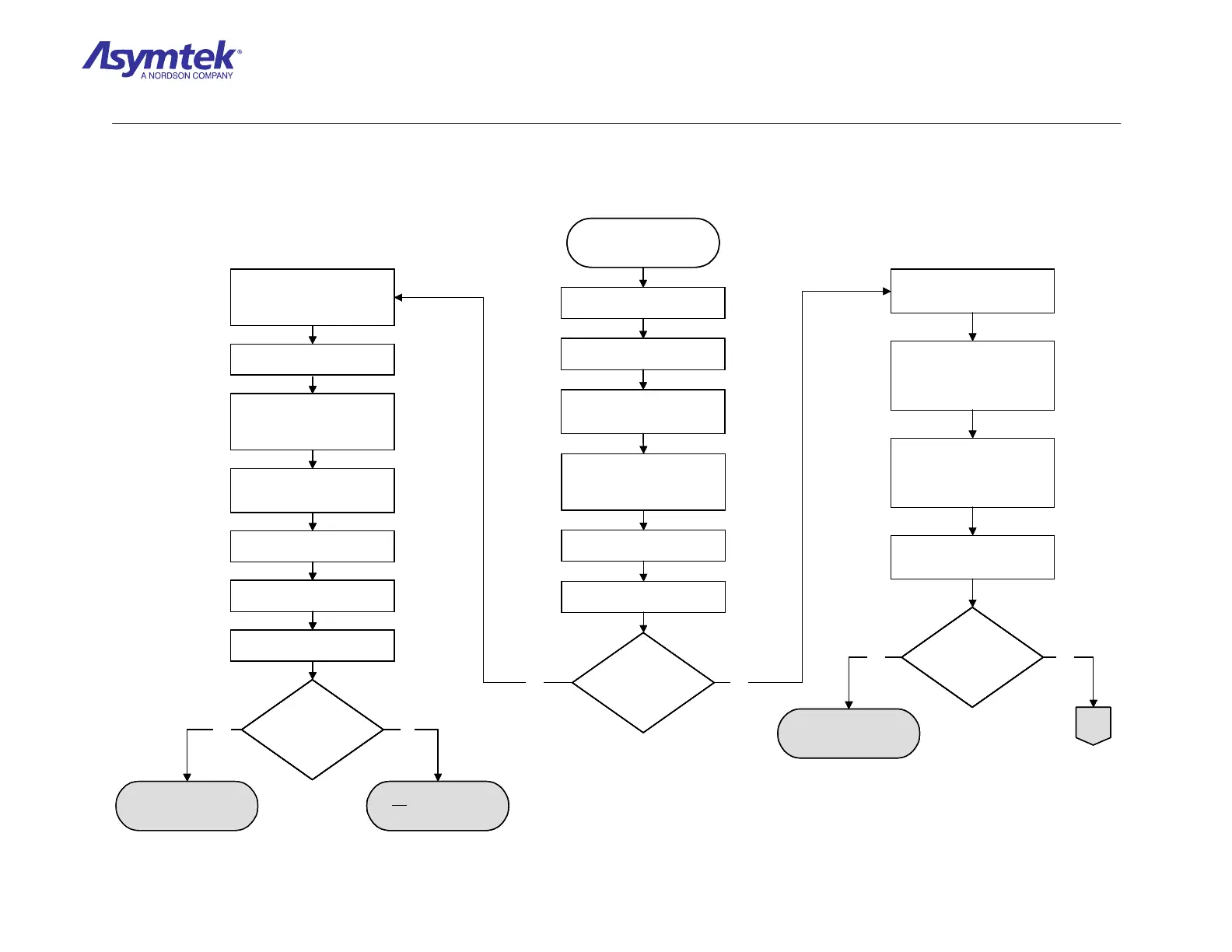

Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-73 PN 1965155 (Revision A)

Stop! Rotary Encoder is

root cause of following

error fault.

Manually move the Dispensing

Head to the mechanical hard

stops in the front left corner of

the dispensing chamber.

Type M101 and press [Enter] on

Keyboard. Note value returned.

Manually move the Dispensing

Head in random directions at

different speeds trying to cover

the whole dispensing chamber.

Return Dispensing Head to the

mechanical hard stops in front

left corner of the chamber.

Again, type M101 and press

[Enter]. Note the value returned.

Repeat the above steps three

times.

Is difference of

any set of values

greater than 200

counts?

Record the difference between

the numeric values noted.

X-axis Rotary Encoder

is not

root cause of fault.

Go to Y-axis Rotary

Encoder Verification

Yes No

A

Remove Servo Motor Cover

located at the rear of dispensing

system below the Servo Shelf.

Rotary Encoder Cable (P/N 06-

4535-00) should be connected to

the X-axis Servo Motor Amplifier

at J3 labeled Rotary Encoder and

the X-axis Servo Motor.

At the X-axis Servo Motor, the

black wire on Rotary Encoder

Cable should be orientated to

Pin 1 labeled GND with the

copper lead facing you.

Carefully remove the Servo

Motor Connector (leads are

fragile) and check for damage.

Are any of the

Servo Motor

Connector leads

damaged?

Servo Motor (P/N 62-

1650-01) has failed.

Yes No

Manually move the Dispensing

Head in the X-axis.

Again, type M101 and press

[Enter]. Note the value returned.

Are the two

numerical values

different?

In the Tools Menu, click on

the Terminal icon.

From the FmNT Main Menu,

click on the Tools icon.

Under the Terminal icon, click

on the Dispenser icon.

Press the black OFF (0)

button on the Operator’s

Console.

In Dispenser Terminal

Window, type M101 and

press [Enter]. Note value

returned.

Yes No

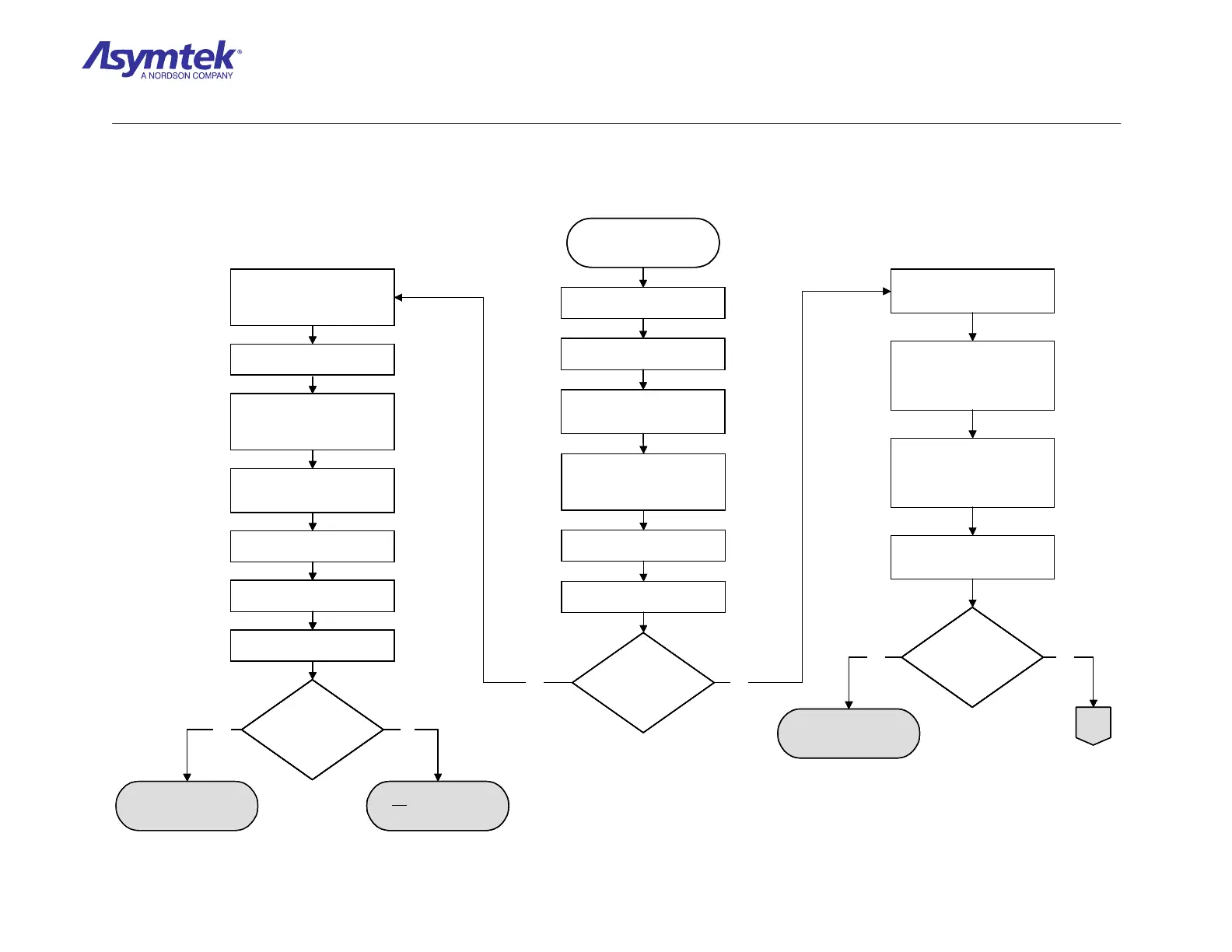

Stop! Rotary Encoder is

root cause of following

error fault.

Manually move the Dispensing

Head to the mechanical hard

stops in the front left corner of

the dispensing chamber.

Type M101 and press [Enter] on

Keyboard. Note value returned.

Manually move the Dispensing

Head in random directions at

different speeds trying to cover

the whole dispensing chamber.

Return Dispensing Head to the

mechanical hard stops in front

left corner of the chamber.

Again, type M101 and press

[Enter]. Note the value returned.

Repeat the above steps three

times.

Is difference of

any set of values

greater than 200

counts?

Record the difference between

the numeric values noted.

X-axis Rotary Encoder

is not

root cause of fault.

Go to Y-axis Rotary

Encoder Verification

Yes No

Manually move the Dispensing

Head to the mechanical hard

stops in the front left corner of

the dispensing chamber.

Type M101 and press [Enter] on

Keyboard. Note value returned.

Manually move the Dispensing

Head in random directions at

different speeds trying to cover

the whole dispensing chamber.

Return Dispensing Head to the

mechanical hard stops in front

left corner of the chamber.

Again, type M101 and press

[Enter]. Note the value returned.

Repeat the above steps three

times.

Is difference of

any set of values

greater than 200

counts?

Is difference of

any set of values

greater than 200

counts?

Record the difference between

the numeric values noted.

X-axis Rotary Encoder

is not

root cause of fault.

Go to Y-axis Rotary

Encoder Verification

Yes No

A

Remove Servo Motor Cover

located at the rear of dispensing

system below the Servo Shelf.

Rotary Encoder Cable (P/N 06-

4535-00) should be connected to

the X-axis Servo Motor Amplifier

at J3 labeled Rotary Encoder and

the X-axis Servo Motor.

At the X-axis Servo Motor, the

black wire on Rotary Encoder

Cable should be orientated to

Pin 1 labeled GND with the

copper lead facing you.

Carefully remove the Servo

Motor Connector (leads are

fragile) and check for damage.

Are any of the

Servo Motor

Connector leads

damaged?

Servo Motor (P/N 62-

1650-01) has failed.

Yes No

A

Remove Servo Motor Cover

located at the rear of dispensing

system below the Servo Shelf.

Rotary Encoder Cable (P/N 06-

4535-00) should be connected to

the X-axis Servo Motor Amplifier

at J3 labeled Rotary Encoder and

the X-axis Servo Motor.

At the X-axis Servo Motor, the

black wire on Rotary Encoder

Cable should be orientated to

Pin 1 labeled GND with the

copper lead facing you.

Carefully remove the Servo

Motor Connector (leads are

fragile) and check for damage.

Are any of the

Servo Motor

Connector leads

damaged?

Are any of the

Servo Motor

Connector leads

damaged?

Servo Motor (P/N 62-

1650-01) has failed.

Yes No

Manually move the Dispensing

Head in the X-axis.

Again, type M101 and press

[Enter]. Note the value returned.

Are the two

numerical values

different?

Are the two

numerical values

different?

In the Tools Menu, click on

the Terminal icon.

From the FmNT Main Menu,

click on the Tools icon.

Under the Terminal icon, click

on the Dispenser icon.

Press the black OFF (0)

button on the Operator’s

Console.

In Dispenser Terminal

Window, type M101 and

press [Enter]. Note value

returned.

Yes No

Diagram Sheet 4-6-4

PMAC Rotary Encoders Fault Isolation Procedure – X-Axis Rotary Encoder Verification

Loading...

Loading...