13 - 5

13 Maintenance and Inspection

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

13-4 Method for Broken Ring Maintenance and Inspection

13

13-4 Method for Broken Ring Maintenance

and Inspection

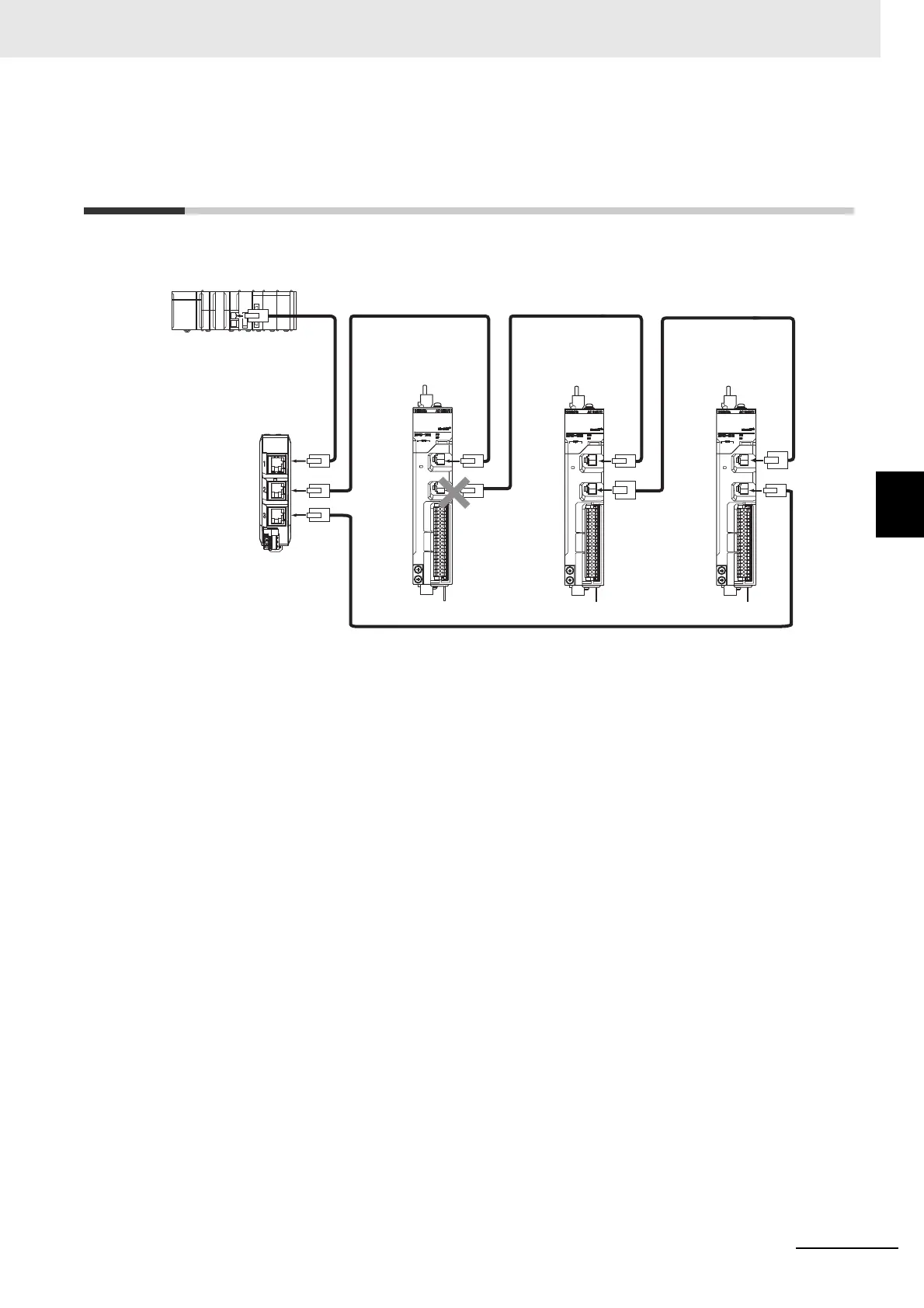

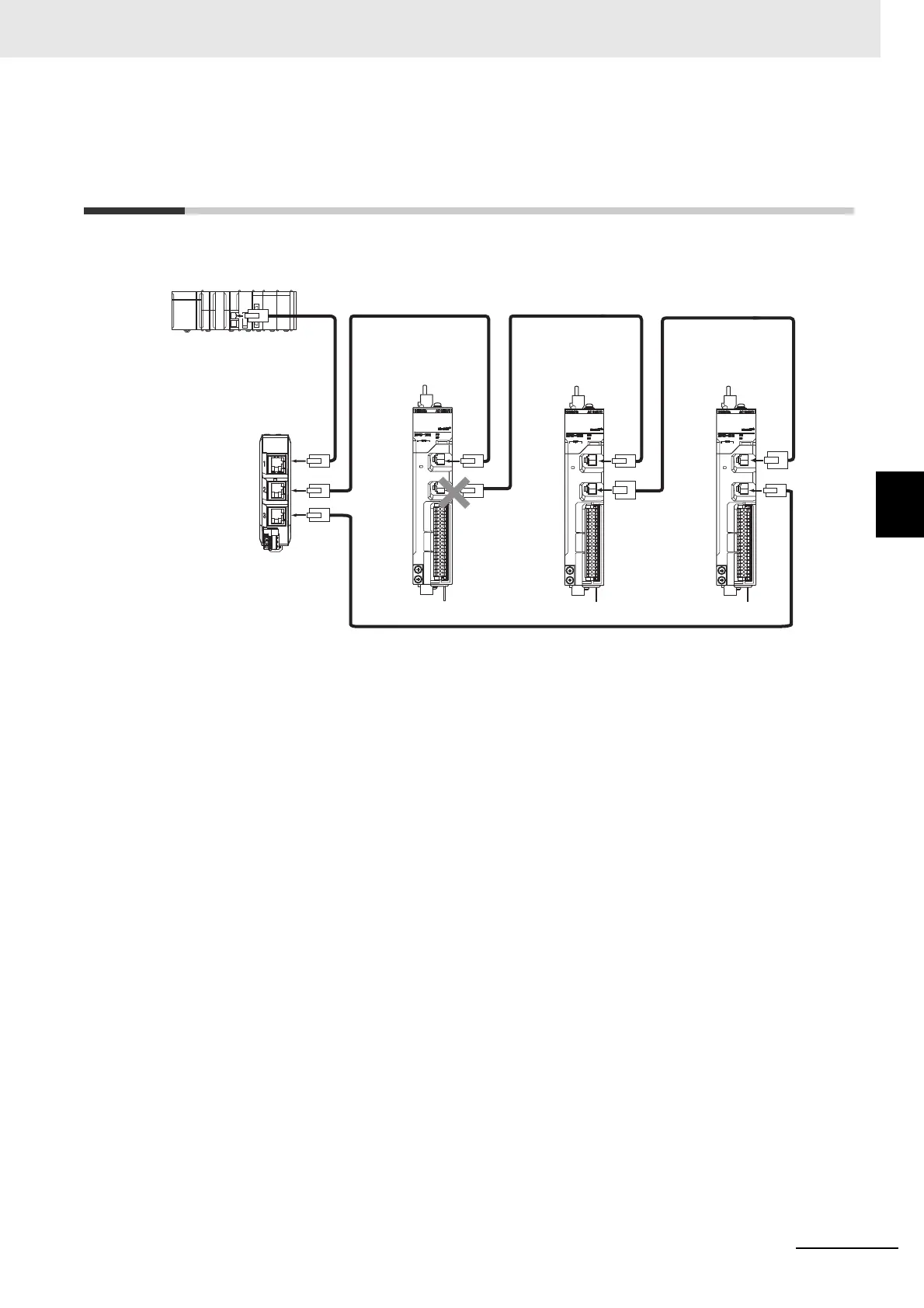

This section takes the following example of a configuration in which the ring is broken between Servo

Drive A and B, and describes how to perform inspection and how to replace the Servo Drive.

1 Identify where the ring is broken.

• With a tool such as support software, find the node address of the Servo Drive breaking the

ring. For the NJ/NX-series Controller, check the _EC_RingBreakNodeAdr system-defined

variable that will provide you with the node address of Servo Drive A. Check that the L/A OUT

indicator of Servo Drive A and the L/A IN indicator of Servo Drive B are OFF.

2 Reconnect the EtherCAT communications cable between Servo Drive A and B.

• Stop operation and turn OFF the power supply to the EtherCAT master and to the slaves.

• After the charge lamps of Servo Drive A and B turn OFF, reconnect the EtherCAT communi-

cations cable, and then turn ON the control power supply to Servo Drive A and B.

• If the L/A OUT indicator of Servo Drive A and the L/A IN indicator of Servo Drive B are ON,

the ring disconnection status has been fixed.

• If the L/A IN and L/A OUT indicators are OFF, the ring disconnection status has not been fixed

yet. Move on to the next step.

3 Replace the relevant cable with a new EtherCAT communications cable.

• Replace the EtherCAT communications cable between Servo Drive A and B with a new cable.

To avoid incorrect wiring, do not remove any other cable.

• If the L/A OUT indicator of Servo Drive A and the L/A IN indicator of Servo Drive B are ON or

blink, the ring disconnection status has been fixed.

• If the L/A IN and L/A OUT indicators are OFF, Servo Drive A or B is faulty. Move on to the next

step.

4 Identify the faulty Servo Drive.

• As in the following figure, connect one EtherCAT communications cable to the ECAT IN and

ECAT OUT connectors on Servo Drive A. If the L/A IN and L/A OUT indicators remain OFF,

Servo Drive A is faulty.

• In the same way, connect one EtherCAT communications cable to the ECAT IN and ECAT

OUT connectors on Servo Drive B. If the L/A IN and L/A OUT indicators remain OFF, Servo

Drive B is faulty.

L1 L2

L5

L3

Servo Drive A Servo Drive B

L4

Servo Drive C

RUN IN OUT

FS

L/A L/A

ERR

RUN IN OUT

FS

L/A L/A

ERR

RUN IN OUT

FS

L/A L/A

ERR

Loading...

Loading...