13 Maintenance and Inspection

13 - 4

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

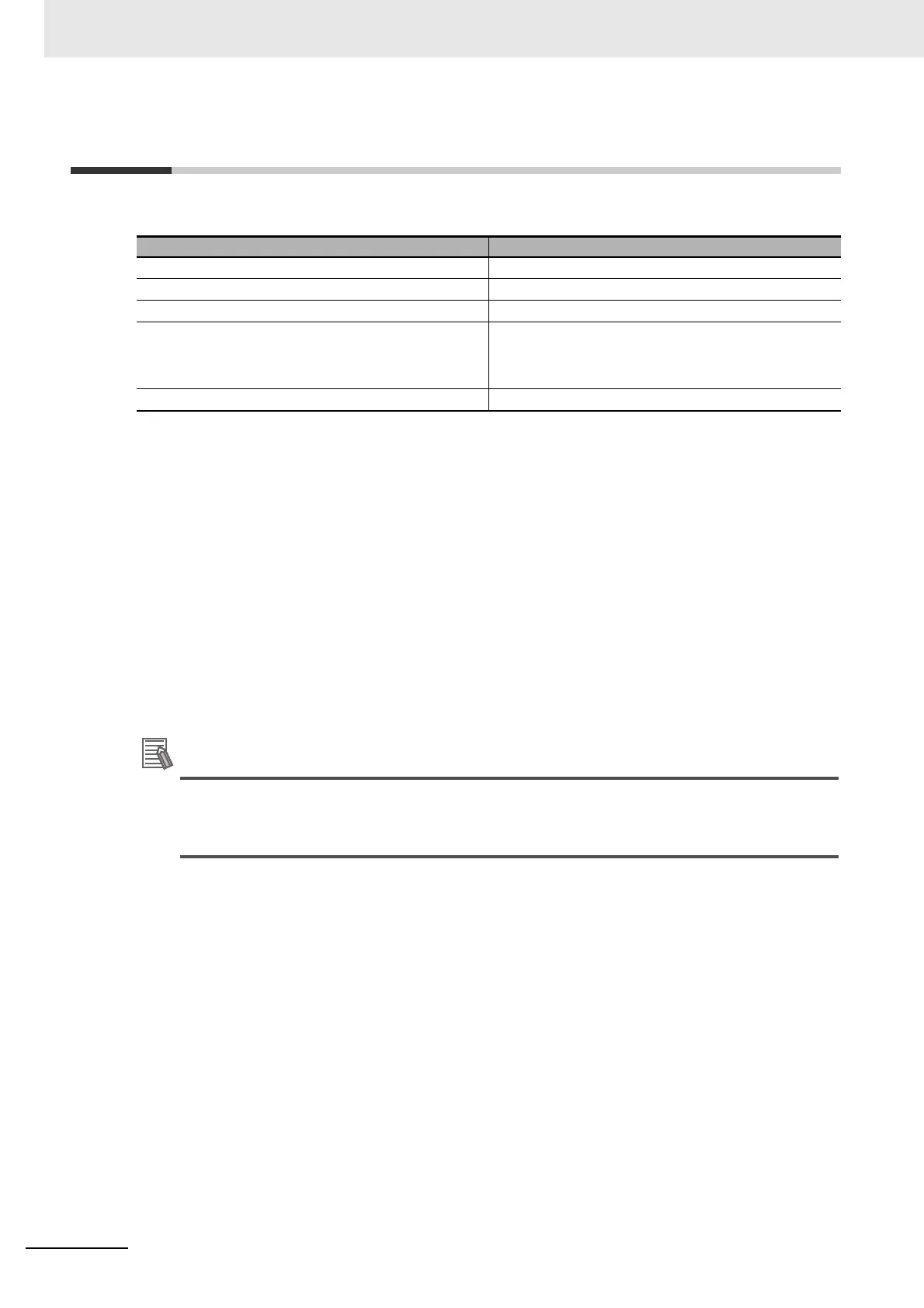

13-3 Servomotor Lifetime

The lifetimes for the different motor parts are listed below.

The operating conditions are determined as follows.

• Operating ambient temperature: 40°C

• Within the range of allowable axial load

• Rated operation (rated torque and rated rotation speed)

• Installation as specified in this manual

• Operation is not repeated with the motor shaft rotation at an angle of 45° or less, which causes the

fretting.

Oil seal can be replaced for repair.

When the Servomotor is used for a belt hook such as timing pulley, the radial load during motor opera-

tion is generally two or more times the static load. Consult with the belt and pulley manufacturers to

adjust designs and system settings so that the motor allowable axial load is not exceeded even during

operation. If the Servomotor is used under a shaft load that exceeds the allowable limit, the motor shaft

can be broken and the bearings can be damaged.

If the Encoder Lifetime Warning occurs, we recommend you to replace the encoder within a few

weeks.

This warning also occurs when the encoder breaks due to impact on the axis.

Name Lifetime

Bearing 20,000 hours

Decelerator 20,000 hours

Oil seal 5,000 hours (models with oil seal)

Encoder

All 3 kW or more models and 2 kW 1,000-r/min

(200/400 V) models

30,000 hours

Brake ON/OFF 1,000,000 times

Loading...

Loading...