Installing cable fittings

OmniTrax Product Guide Page 125

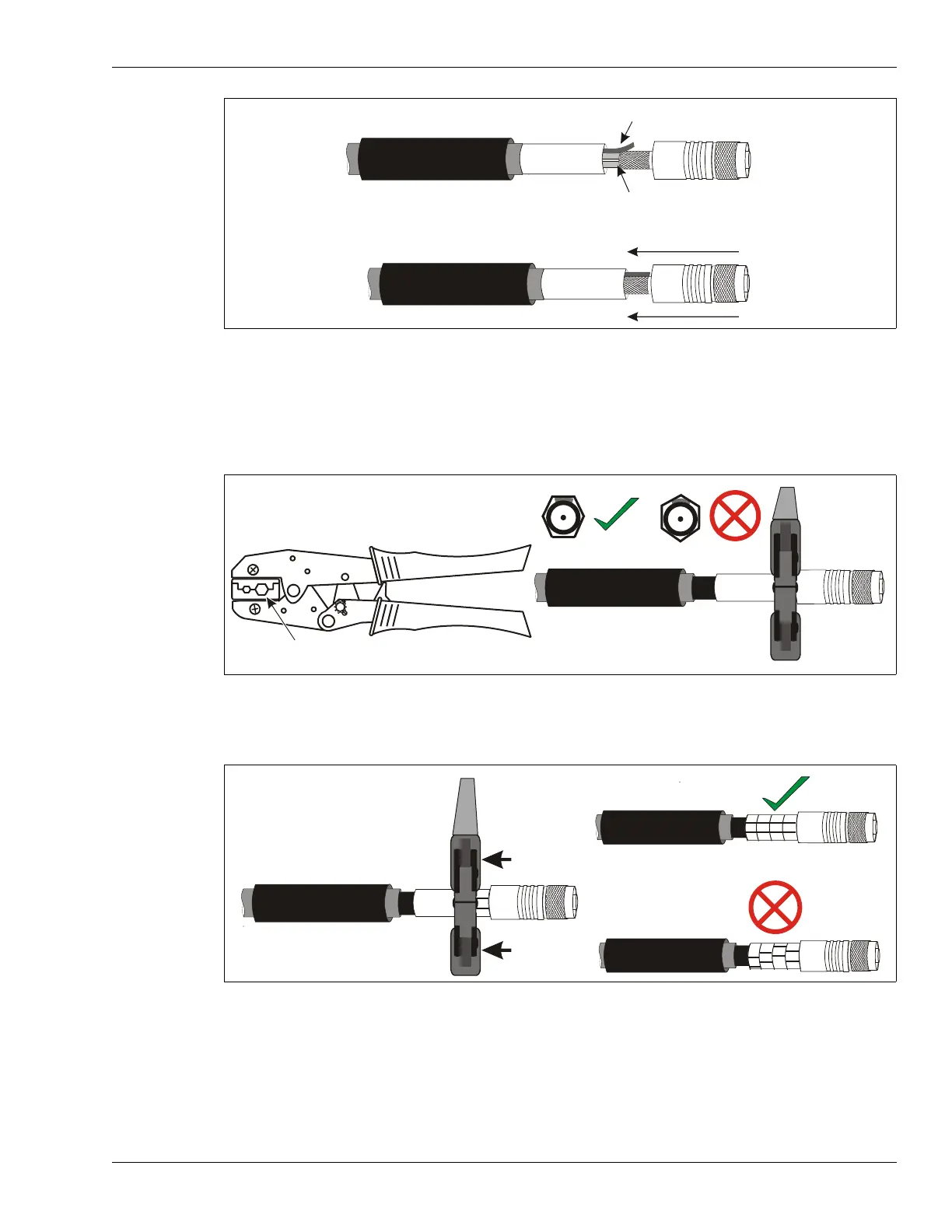

5. Firmly, press the connector shell onto the sensor cable until the midsection is flush with the

outside end of the crimp ring.

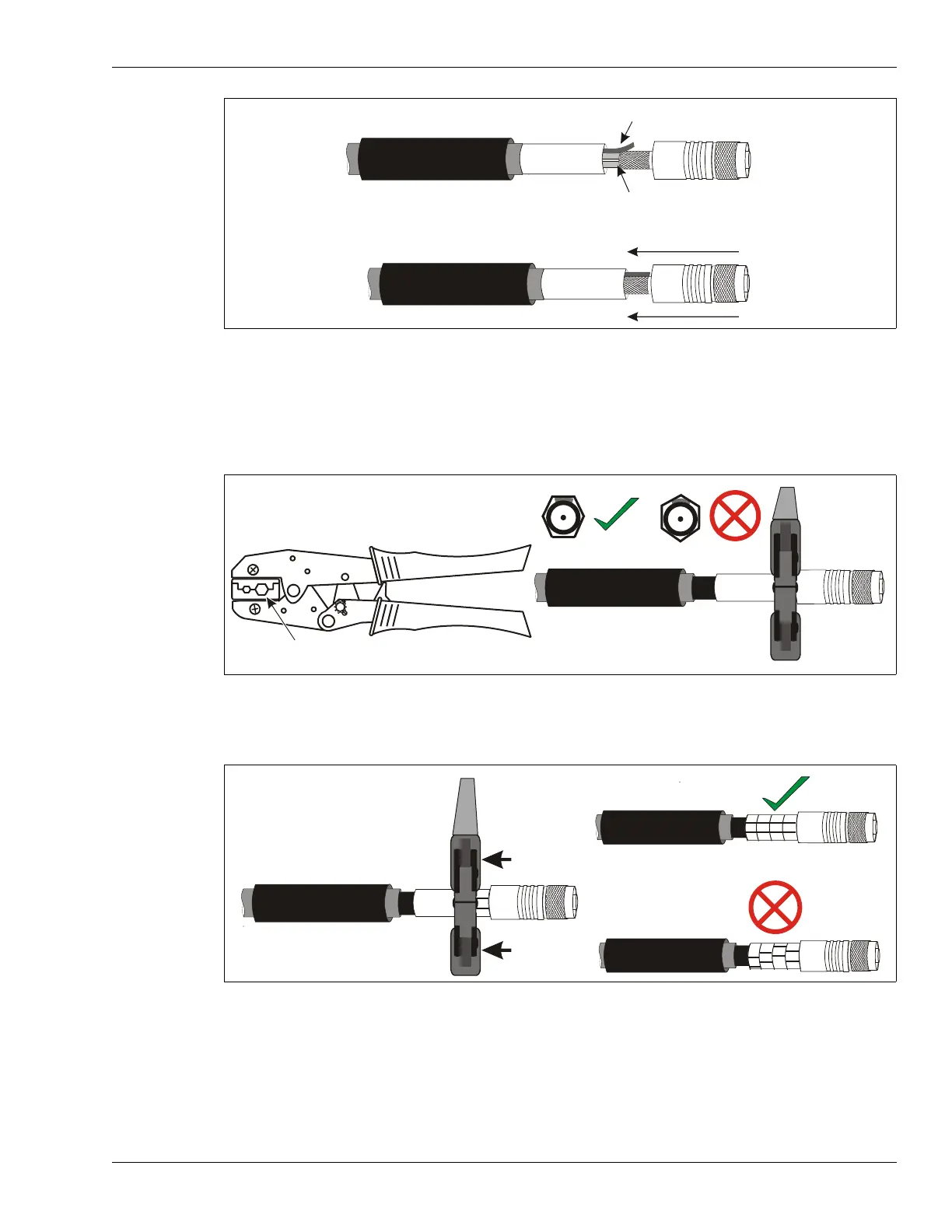

6. Using the larger hexagonal hole (.429) position the crimp tool over the crimp ring so that the

edge of the crimp tool is right against the smooth midsection of the connector, and a flat

crimping surface is directly above the drain braid. Make the first crimp.

7. Open the crimp tool, and without rotating the crimp tool, connector, or sensor cable, move the

crimp tool over the uncrimped area beside the first crimp and make a second crimp.

8. Make two more crimps so that the full length of the crimp ring is crimped, and the four crimps

are lined up straight.

9. Slide the heatshrink over the crimp until it covers the smooth portion of the connector’s

midsection. DO NOT allow the heatshrink to cover any portion of the rotating end of the

connector.

Figure 93: OC2 connector installation

Figure 94: Making the first crimp

Figure 95: Making the second crimp

drain braid outside connector shell

center pin, foil and dielectric core inside connector shell

press the connector shell onto the cable until the midsection is flush against the crimp ring

Connex crimp tool

use only the larger hexagonal opening (.429)

make the first crimp at the edge of

the smooth midsection of the

connector shell above the location

of the drain braid

Ensure that the four crimps line

up with no deviation.

Loading...

Loading...