Installing cable fittings

Page 126 OmniTrax Product Guide

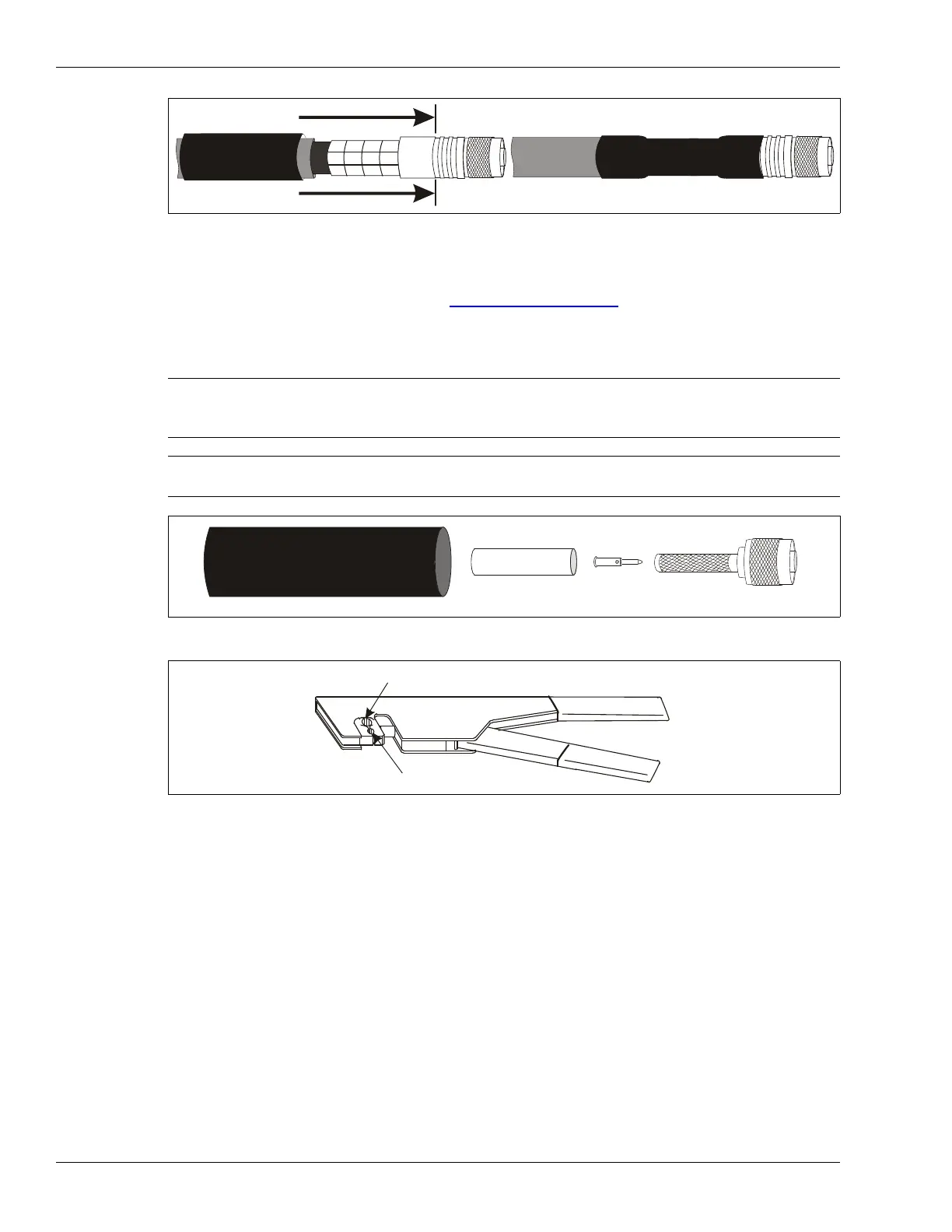

10. Using a heatgun, apply heat evenly across the heatshrink until it fits tightly over the assembly.

The rotating end of the connector MUST turn freely.

11. Verify the connector installation (see Cable tests

on page 146).

Installing connectors on SC1 and SC2 sensor cable

• all connections must be clean and dry - use a heat gun to remove moisture

• do NOT blow on a connector to clean it

• do NOT drop or place the connectors, cable ends, terminators or decouplers on the ground or

allow them to get wet or dirty

• before installing connectors and connecting cables to the processor, cut off the excess lead-in,

ensuring that there is a minimum of 6 m (20 ft.) of lead-in cable and there is enough lead-in

cable to create a 2 m (6.5 ft.) service loop at the processor

Required tools

• SC1/SC2 connector tool kit (P/N A0KT1500) including:

•knife

• large cutting pliers

• small cutting pliers

Figure 96: Completing the connector installation

Note The following procedure applies to SC1/SC2 connector parts kit

A0SP0700-003. For SC1/SC2 connector parts kit A0SP0700-002,

follow the instructions (A3DA0403-001) that are included in the kit.

Note Use ONLY the supplied connector kits, and the specified crimp tool with

the SC1 and SC2 cables.

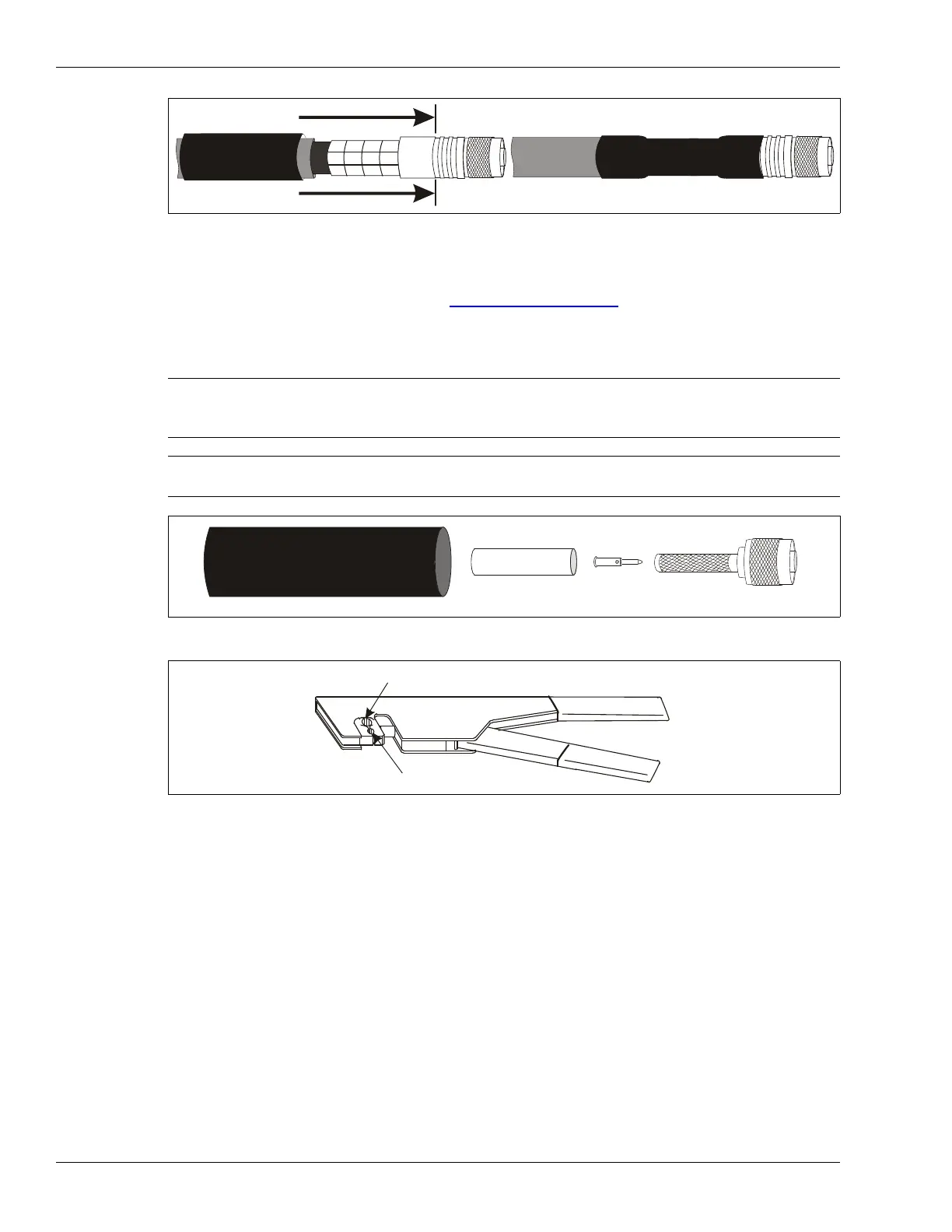

Figure 97: Connector parts kit A0SP0700-003

Figure 98: SC1/SC2 crimp tool

heatshrink

crimp ring

center pin

TNC connector shell

use the large hex opening for the crimp ring

use the small quad opening for the center pin

Loading...

Loading...