Installing cable fittings

Page 124 OmniTrax Product Guide

7. Ensure that the exposed center conductor is straight.

8. If necessary, remove any residue from the center conductor.

9. Using the deburring tool, deburr the end of the center conductor so that it is smooth and

rounded.

Part 2: Installing the connector

1. Press the center pin firmly onto the center conductor. There should be approximately 2 mm of

exposed center conductor showing between the center pin and dielectric core.

2. Slide the heatshrink over the sensor cable’s gray jacket.

3. Slide the crimp ring over the stripped sensor cable and drain braid until it butts up against the

gray jacket.

4. Lift the drain braid slightly, and then fit the connector shell onto the sensor cable, so the center

pin, foil and dielectric core fit smoothly into the connector shell, while the drain braid remains

outside.

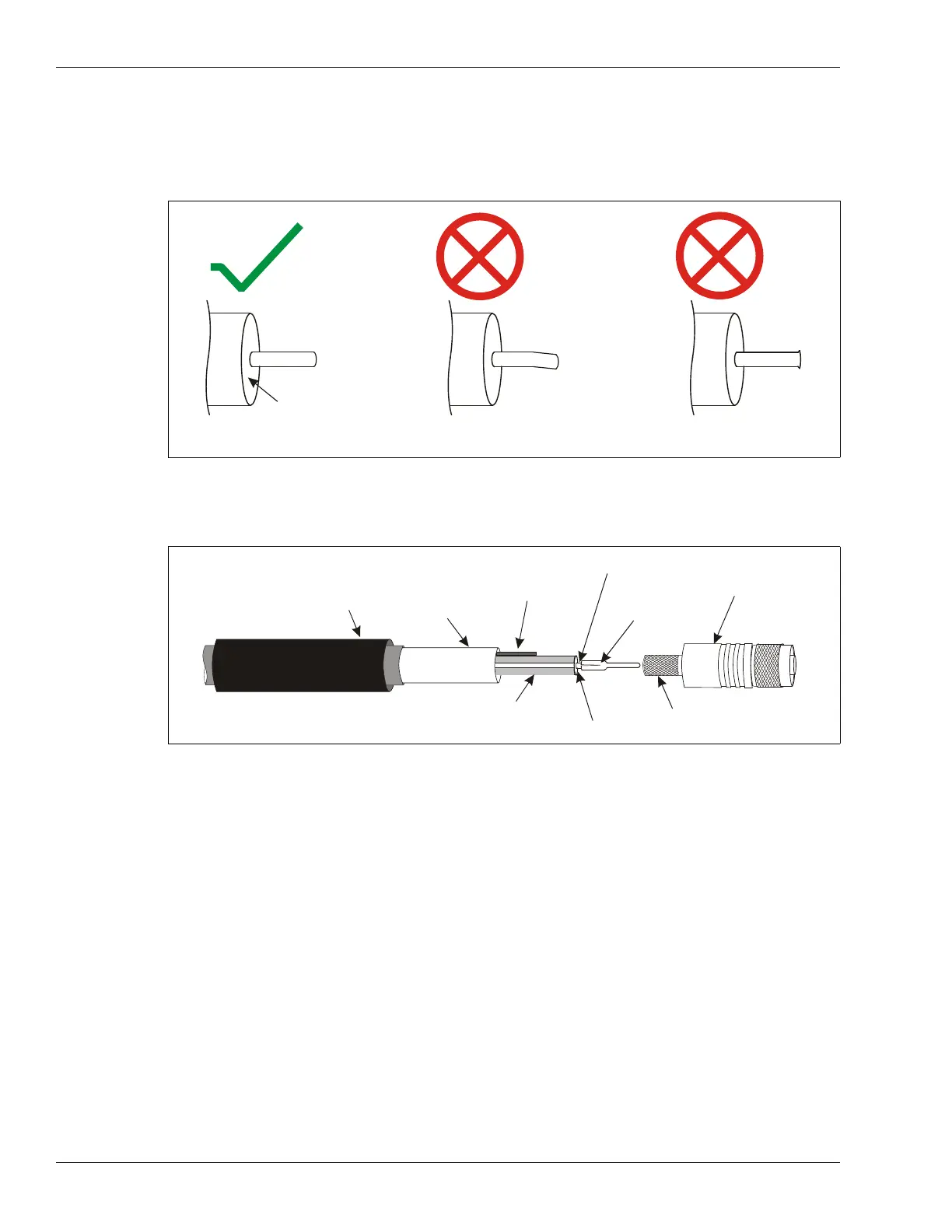

Figure 91: Preparing the center conductor

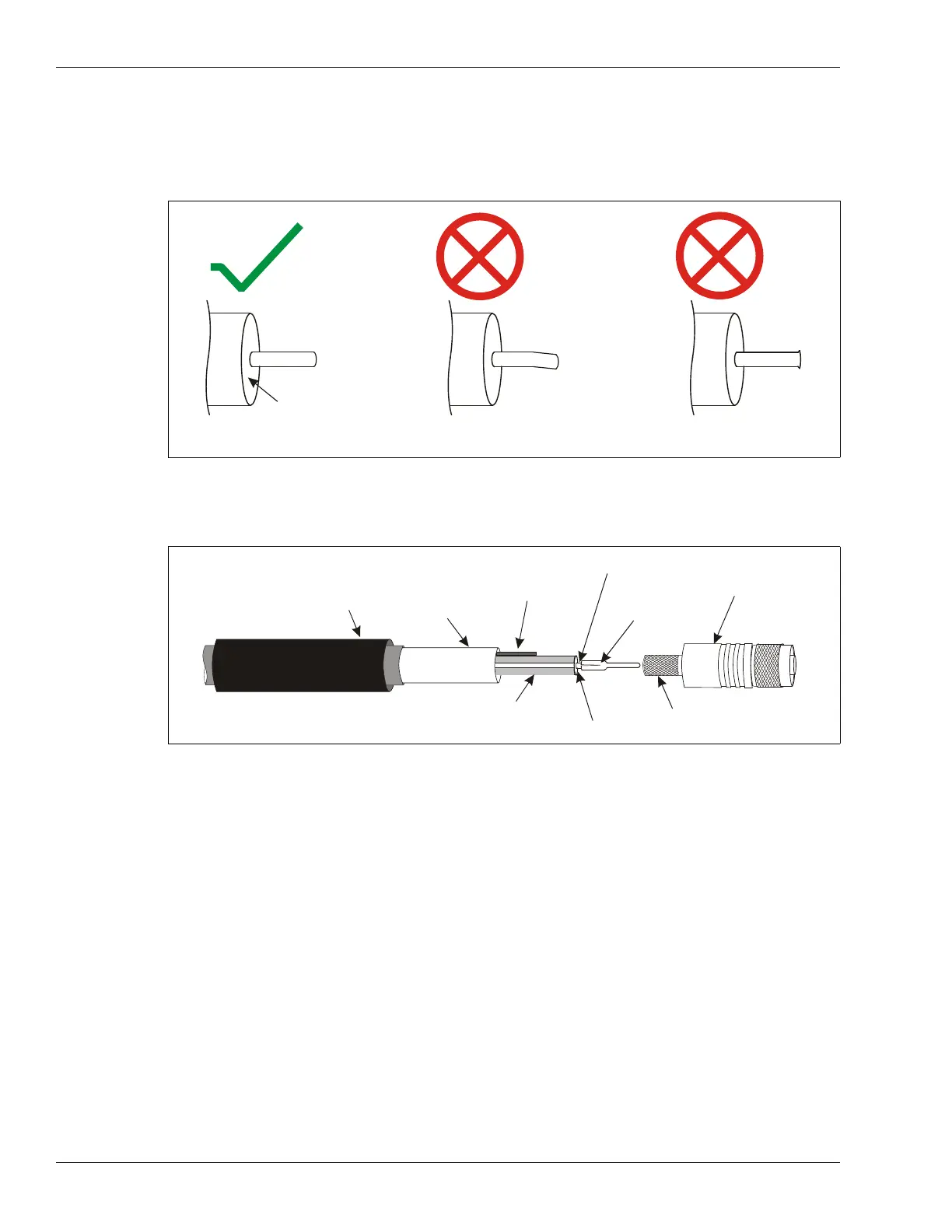

Figure 92: OC2 connector installation

straight with smooth

rounded end

slight bend in

center conductor

burr on end

The center conductor MUST be straight and its end MUST be smooth and rounded. If the end is

bent or there is ANY lip or burr on the center conductor, it will NOT fit correctly into the center pin

CAUTION

no foil on dielectric

cross section

heatshrink

crimp ring

drain braid

connector midsection

center pin

center conductor

foil

dielectric core

connector shell

Loading...

Loading...