6. Remove the hex head screw on the Power Drawbar

cylinder’s rod with an adjustable wrench, and set it

aside.

Figure 4-95: Hex head screw on the Power Drawbar

cylinder's rod.

7. Remove the M16 washer from the Power Drawbar

cylinder’s rod, and set it aside.

Figure 4-96: M16 washer removed from the Power

Drawbar cylinder's rod.

8. Put the hex head screw back in, and then tighten it

completely with an adjustable wrench.

9. Pivot the Power Drawbar cylinder to the original location.

10. Push in the quick-release pin.

11. Reconnect the shop's air supply to the Power Drawbar

button.

12. Examine the space between the hex head screw on the

Power Drawbar cylinder’s rod and the top of the

drawbar.

13. Verify that the gap is between 3/64 in. and 1/8 in. (1

mm and 3 mm). Depending on the size of the gap, do

one of the following:

l

Between 3/64 in. and 1/8 in. (1 mm and 3 mm)

You have completed adjusting the initial setup.

l

Less Than 1/8 in. (1 mm) Go to Step 14.

14. Find the three provided M14 flat washers.

15. Put one M14 flat washer under each mounting post on

the Power Drawbar cylinder.

Adjust the Tool Tray Load Position

1. Verify that there's no tool in the spindle.

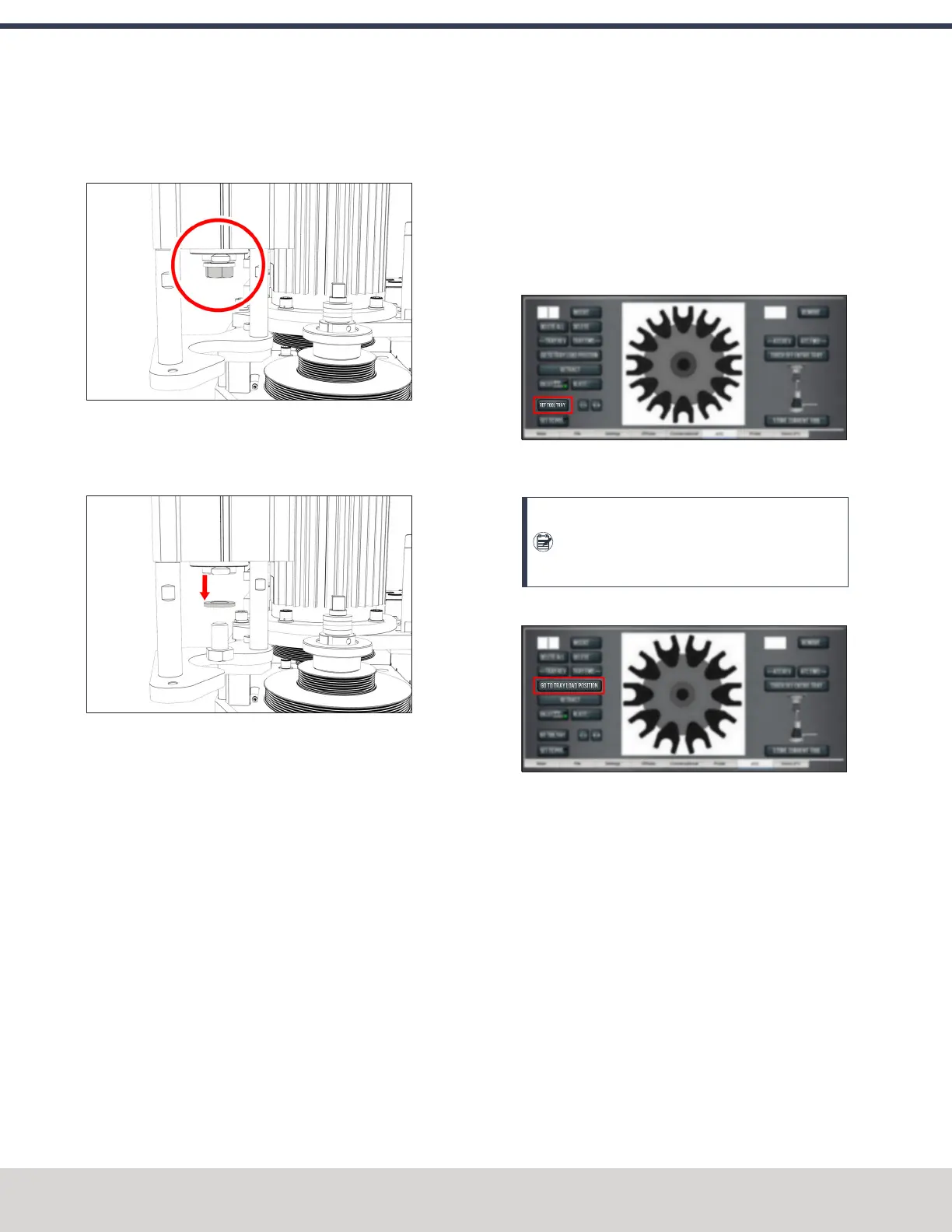

2. From the PathPilot interface, on the ATC tab, select Ref

Tool Tray.

Figure 4-97: Ref Tool Tray button on the ATCtab.

The tool tray spins.

Note: You're only required to reference the tool

tray once, unlike the mill axes’ referencing

procedure.

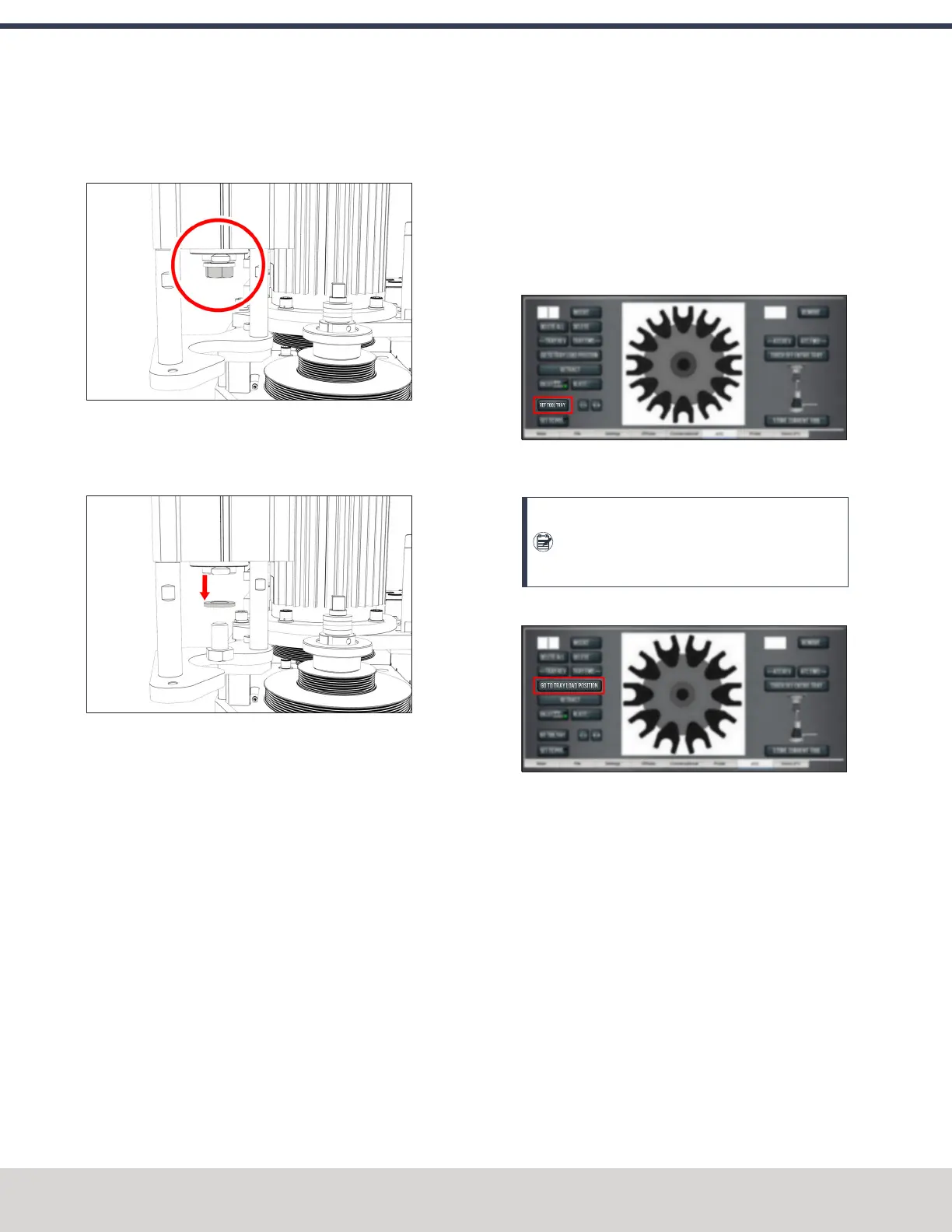

3. Select Go to Tray Load Position.

Figure 4-98: Go to Tray Load Position button on the

ATC tab.

4. When prompted, select OK.

The tool tray moves forward.

5. Put the tool holder with the rod into the fork.

6. From the PathPilot interface, slowly jog the Z-axis down

(-Z) to bring the spindle nose toward the tool in the tool

tray.

7. Make sure that the tool’s shank is aligned concentrically

with the collet in the spindle.

©Tormach® 2023

Specifications subject to change without notice.

Page 76 Tormach 1100M® Operator's Manual (Version 1223A)

For the most recent version, see tormach.com/support

4: INSTALLATION

Loading...

Loading...