4: INSTALLATION

c.

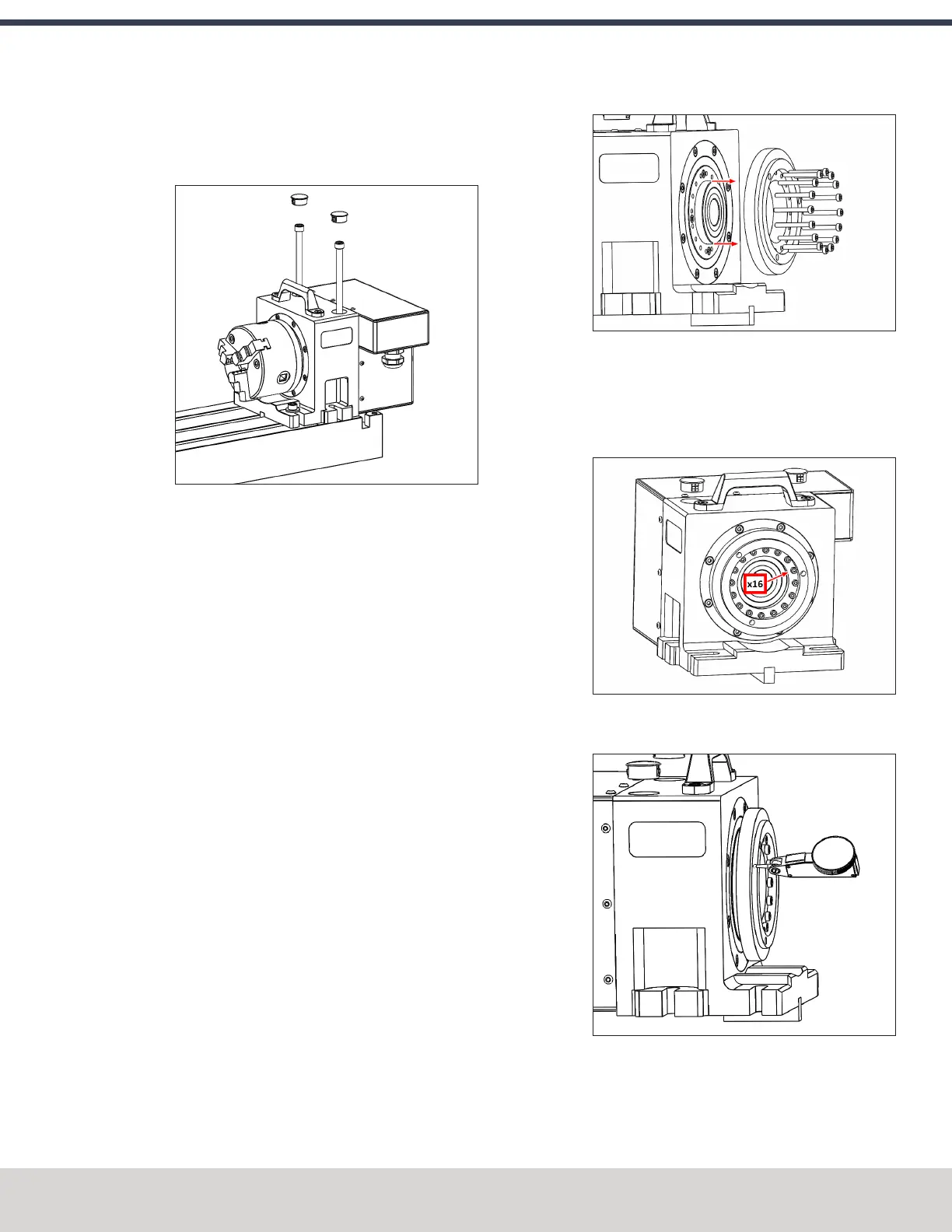

Right Side (Using 6" Through-Bolts into T-Slots)

X work envelope is reduced in this configuration, but

it provides clearance for long tooling in the ATC.

2. Feed the motor cable under the electrical cabinet and

plug it into the 7-pin connector you installed with the

driver kit.

3. Loosely install the 5/16" mounting bolts, using either the

threaded accessory mounting holes on your machine

table or T-nuts.

4. Use the key on the bottom of the 4th axis to perform a

rough alignment of the unit to the T-slots in your

machine's table. If you need to perform a precise

alignment, put a straight test bar into the chuck and

sweep along it in X with an indicator. Adjust the

orientation of the 4th axis until the reading does not

deviate during the sweep.

5. Tighten the mounting hardware with a hex wrench.

Center the Chuck Mounting Plate

1. Remove the chuck from the 4th axis, if installed.

2. From the PathPilot interface, verify that you can rotate

the 4th axis with either the jog keys on the keyboard or

the jog shuttle.

3. The mounting plate is designed for a loose fit onto the

output of the harmonic drive. This allows you to adjust

the center of rotation to control runout at the chuck.

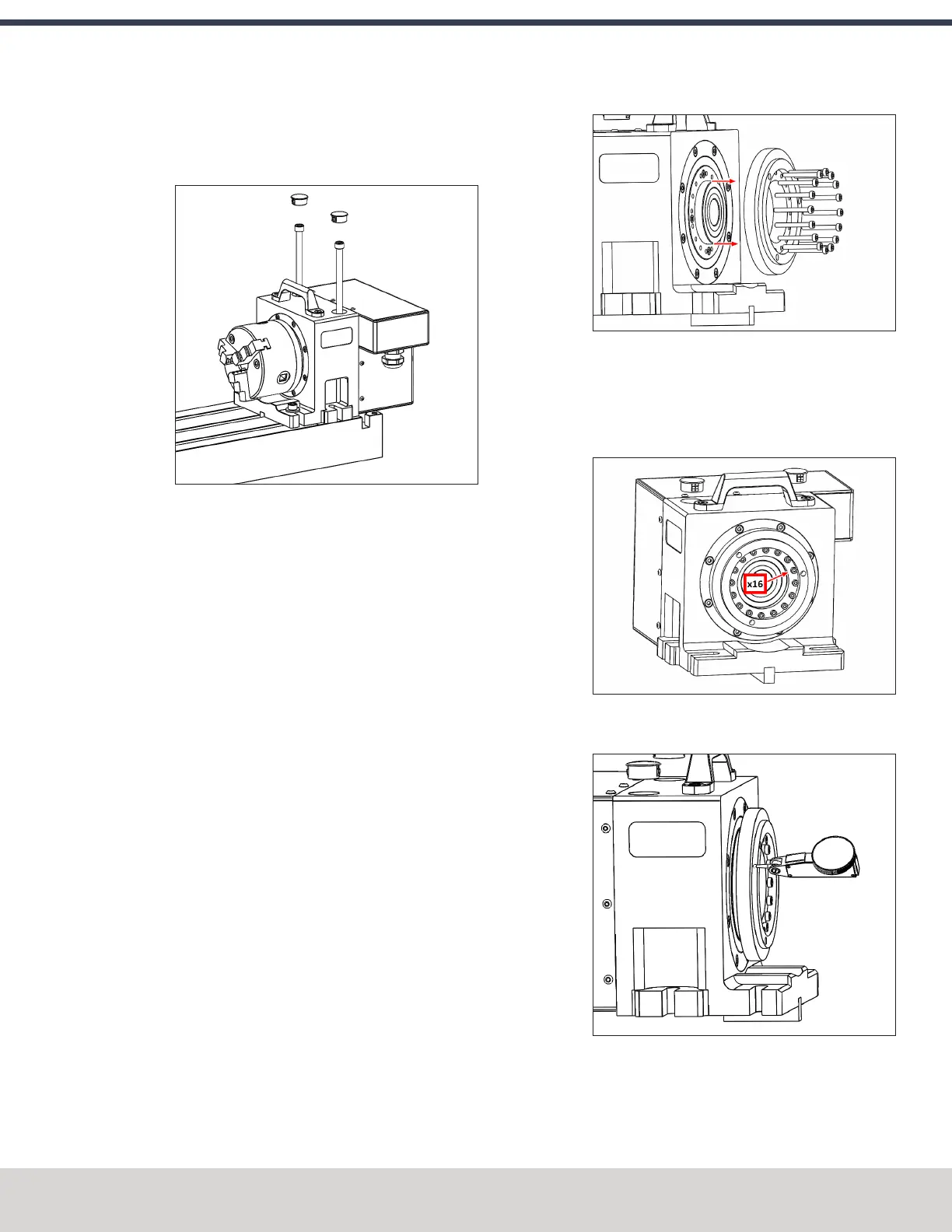

4. Slightly loosen the 16 M3 button head cap screws that

hold the chuck mounting plate to the output of the

harmonic drive. They should still be snug enough that the

mounting plate is held in place by friction but can be

nudged with a dead-blow hammer.

5. Put a the tip of a dial test indicator on the mounting

flange for the chuck.

6. Using PathPilot, jog the 4th axis 360 degrees, noting the

spot where the indicator is highest.

©Tormach® 2023

Specifications subject to change without notice.

Page 83 Tormach 1100M® Operator's Manual (Version 1223A)

For the most recent version, see tormach.com/support

Loading...

Loading...