C Validation andTroubleshooting

C.1 Introduction

To ensure that your machine is working correctly, follow the instructions outlined in the

following sections.

C.2 Validating the cabling installation

1. Connect all devices to the system.

2. Connect the CAN terminators where appropriate.

3. Turn on the ignition.

4. If a device has a power indicator, check that it is lit. If not, see C.8 No power.

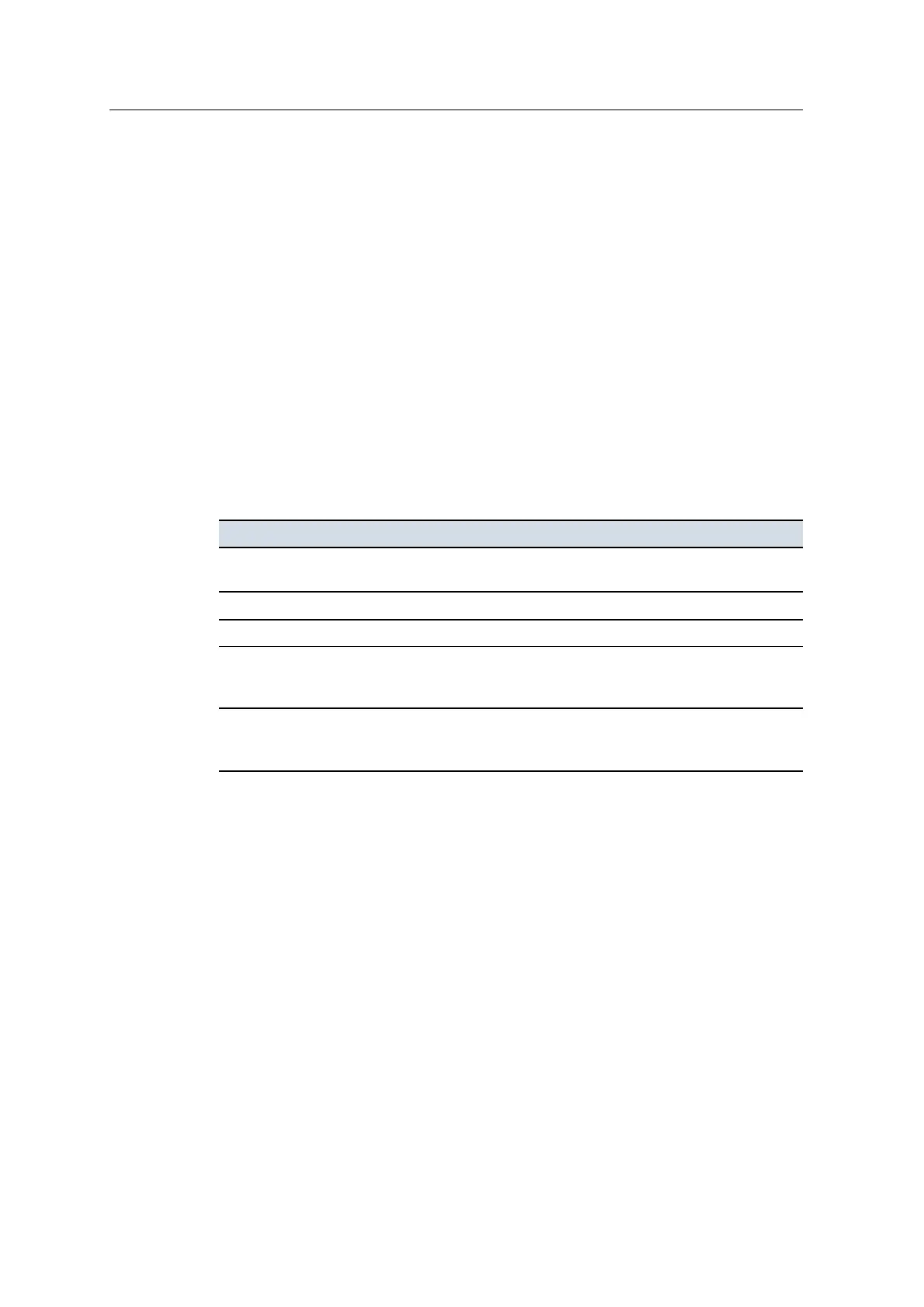

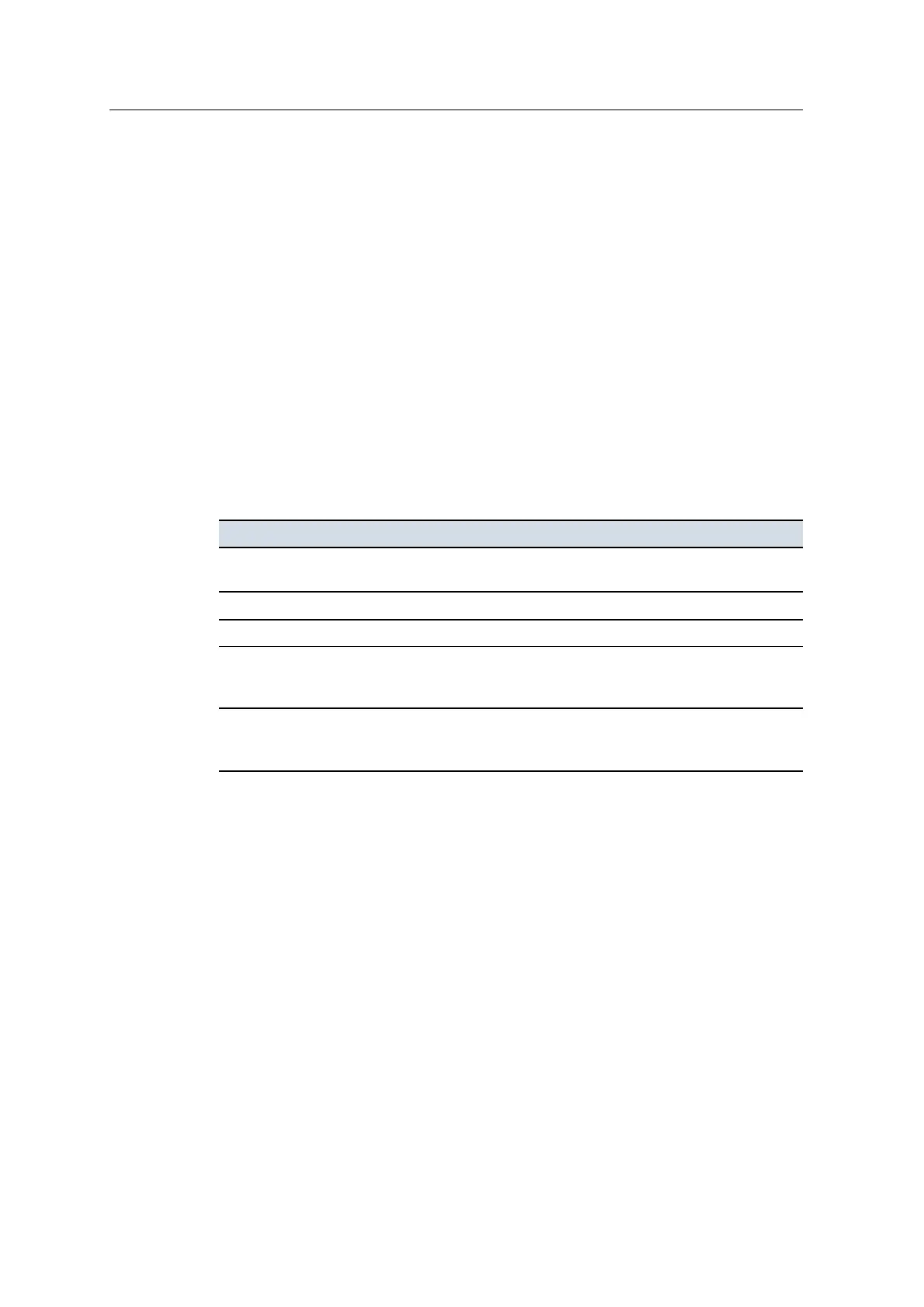

Use a multimeter to validate the harness and cabling installation, as follows:

On the ... Check these pins ... For ...

31-pin cab harness bulkhead

connector

1(+) and 2(–) Battery voltage

39-pin control box connector D(+) and F(–) Battery voltage

6-pin connectors F(+) and A(–) Battery voltage

6-pin connectors J (CAN0 Low)

and K (CAN0 High)

60 ohms: the correct measure for

the CAN bus terminator (with the

power off)

Diagnostics connector D (CAN0 Low)

and C (CAN0 High)

60 ohms: the correct measure for

the CAN bus terminator (with the

power off)

C.3 Validating the tilt bucket

To ensure that the system provides accurate guidance to the bucket tips, you must

validate the tilt bucket.

1. Level the bucket tips.

2. Verify that the bucket appears correctly in cross-section view.

3. Move the bucket to a new position and raise the right bucket tip off the ground

to anywhere between 0.5meters (20inches) and 1meter (39inches).

4. Verify that the bucket appears correctly in cross-section view.

5. Repeat steps 3 and 4, but raise the left bucket tip instead.

164 GCS900 GradeControl System for Excavators Installation Manual

Loading...

Loading...