SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 1

58-25

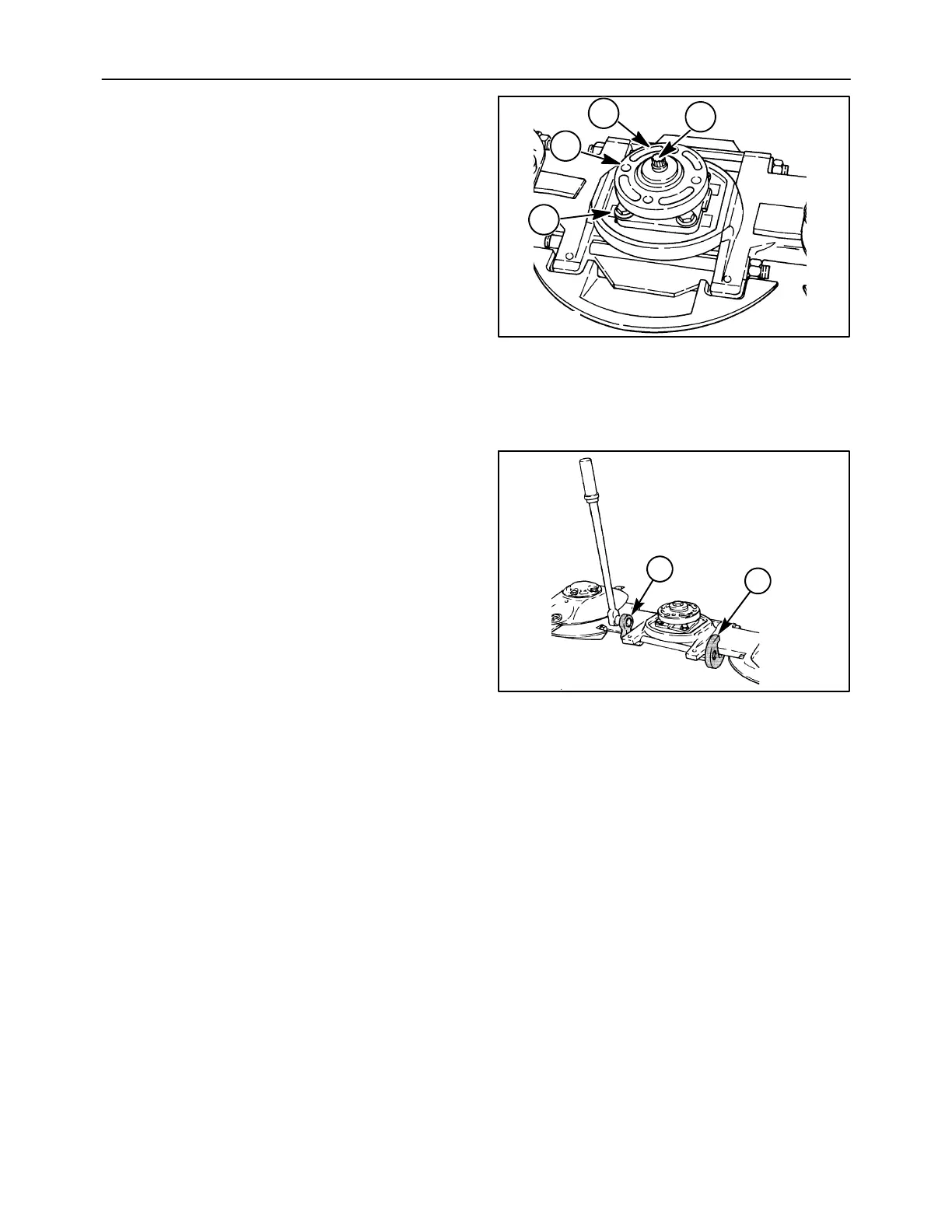

Slide the disc hub, 1, onto the top cap shaft; if it

is not perfectly timed to the adjacent discs,

remove the disc hub, rotate it 90° and reinstall it.

Continue to do this until the disc hub is properly

timed; one of the four positions will provide

correct timing.

NOTE: With the adjacent discs positioned at 90

°

,the

breather, 3, should be completely visible through the

disc hub bolt hole, 4, when the hub is properly timed.

After determining the correct position, apply a

thin coating of grease to the seal lip and sealing

surface on disc hub, and carefully slide disc hub

onto shaft past seal. Apply a small amount of

silicone sealant to the end of the disc hub

retaining bolt, 2, and torque it to 224 N⋅m (150

ft-lb).

19986023

1

2

3

4

58

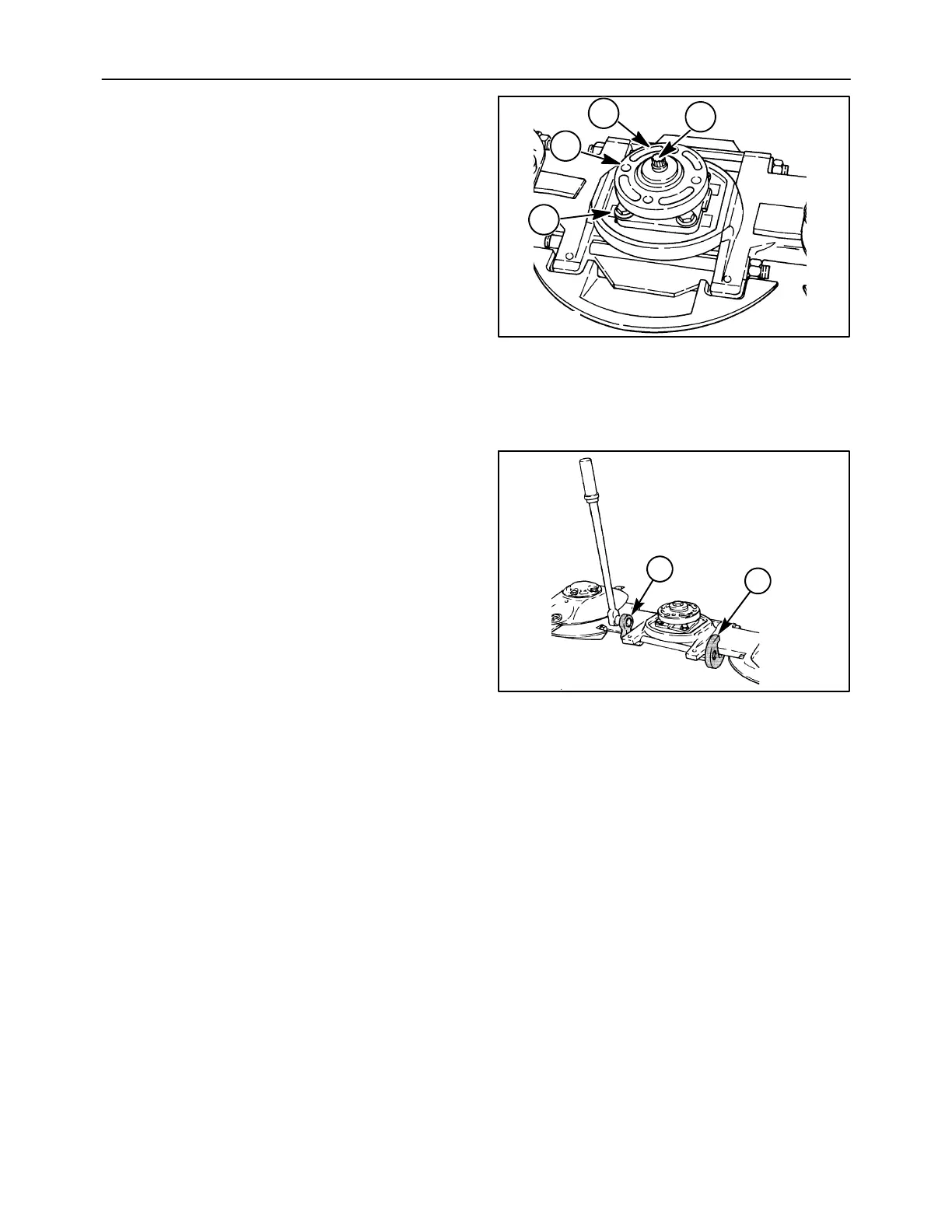

7. The tie bolts which connect the cutter bar

together are torqued using the degree method of

torquing, which requires a special procedure.

Install special holding tools, 1, onto the nuts on

one end of each tie bolt. Then, using special

wrench attachment, 2, with a torque wrench,

tighten both tie bolts to 68 Nám (50 ft-lb).

NOTE: Always torque or turn the rear tie bolt first.

8. Use a marker or scribe to mark the front and rear

nut positions relative to the spacer. Using special

wrench attachment and a 3/4″ breaker bar, turn

each nut 1/2 turn at a time to achieve one full turn

on each tie bolt, starting with the rear tie bolt first.

This will give a total torque on the tie bolt of 68

Nám (50 ft-lb) plus 1 turn, for a clamping force of

15,900 -- 16,800 kg (35,000 -- 37,000 lb).

NOTE: It may be necessary to partially torque the tie

bolts, mount the cutter bar assembly back onto the

unit, and use a cheater bar to obtain enough leverage

to complete tightening the tie bolts.

9. Remove special tools from the cutter bar; it may

be necessary to use a hammer to knock the

special holding tools off of the nuts.

10. Reinstall the rock guard, skid shoe and disc on

the replacement module.

1

2

59

Loading...

Loading...