SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 3

58-14

4. Assemble the second yoke repeating steps 1-3.

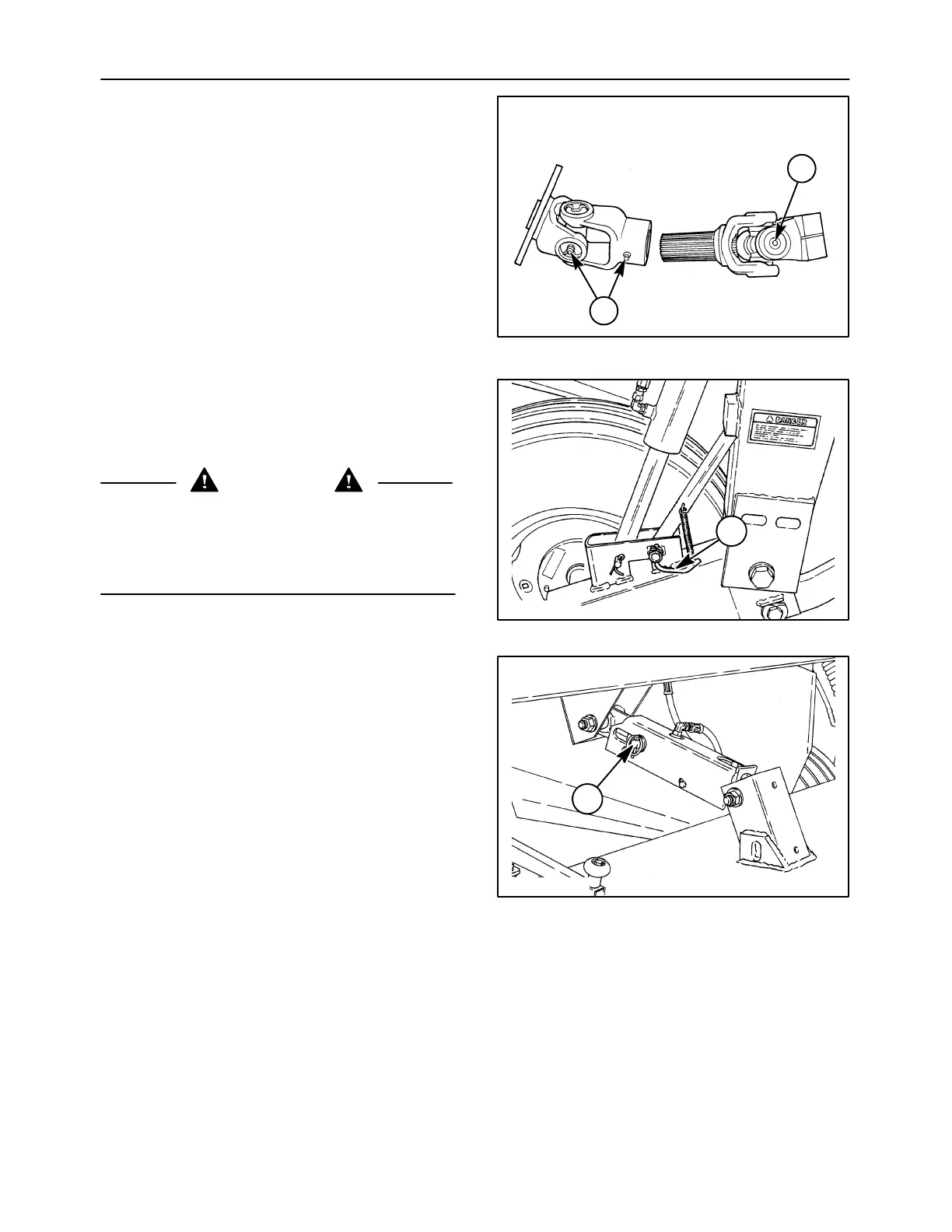

NOTE: The grease zerk, 1, is oriented to line up with

other grease zerks, 2, on the driveline. Note the

positioning of the bearing for the grease zerk during

reassembly.

5. After complete assembly of the U-joint, strike the

forged surfaces of all yoke ears with a sharp blow

from a hammer. This will ensure proper seating

of the bearings, and eliminate any possible

tightness to ensure a free flexing joint.

IMPORTANT: Use caution not to strike the bearing

bore area of the yoke, as this will damage the bore

and may cause premature cross bearing failure.

1411/8-11

1

2

33

LOWER CONDITIONER ROLL - REMOVAL

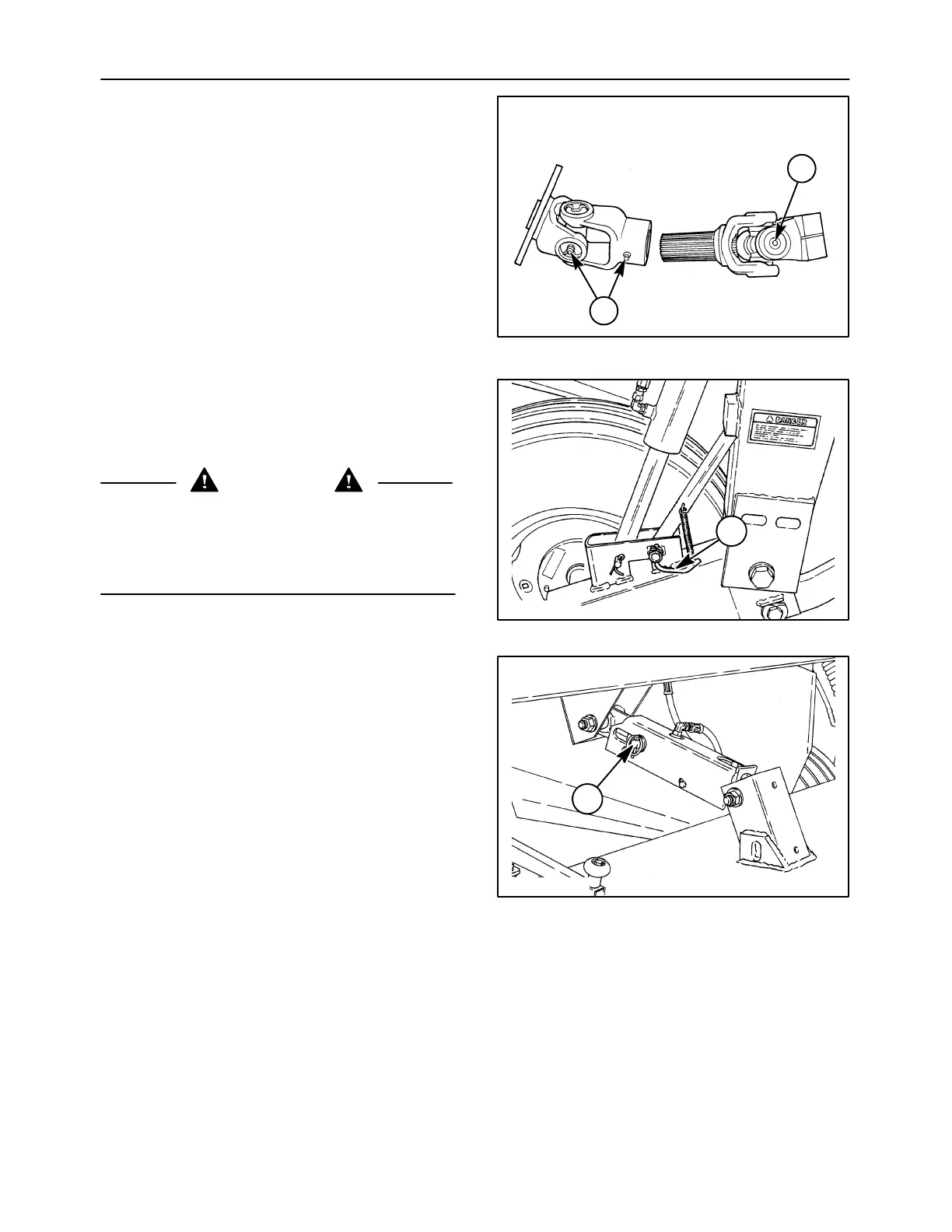

1. Raise the header fully and engage the header lift

transport locks by pivoting both right and left lock

levers,1,forward.

DANGER

The header should be resting on the ground or

suspended in the transport position by the

header lift locks during lubrication or mainte-

nance. Failure to comply will result in death or

serious injury.

A3657-29

1

34

2. Install the header tilt cylinder pin, 1, through the

channel slot and the rear hole of the cylinder rod

to lock the header in the level position. Lower the

header onto the transport locks.

19982132

1

35

Loading...

Loading...