SECTION 00 - GENERAL INFORMATION - CHAPTER 1

00-18

BLEEDING AIR FROM THE LIFT

CYLINDERS

WARNING

Disengage the PTO, turn off the tractor engine

and remove the key. Wait for all movement to

stop before leaving operator’s position. Never

adjust, lubricate, clean or unplug machine with

the engine running. Failure to comply could

result in death or serious injury.

If the lift cylinders do not lift the frame evenly or if one

side lifts higher than the other, rephase the cylinders

by lowering the mower-conditioner and continue to

hold the tractor valve in the lower position for 10 to 15

seconds, or raise the mower-conditioner and

continue to hold the tractor valve in the raise position

for 10 to 15 seconds. If the cylinders do not extend far

enough to release the header lift locks, there may be

air in the hydraulic system that must be purged.

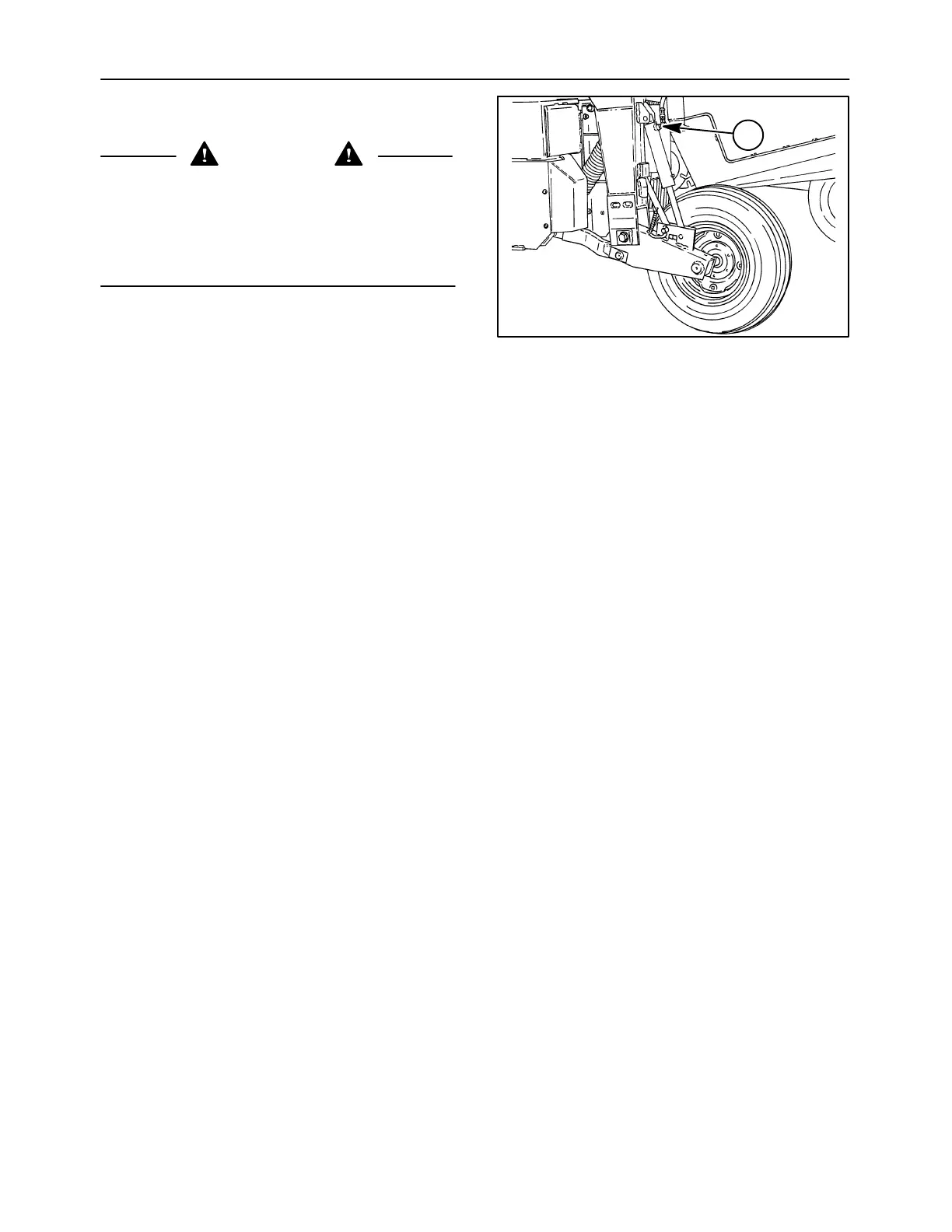

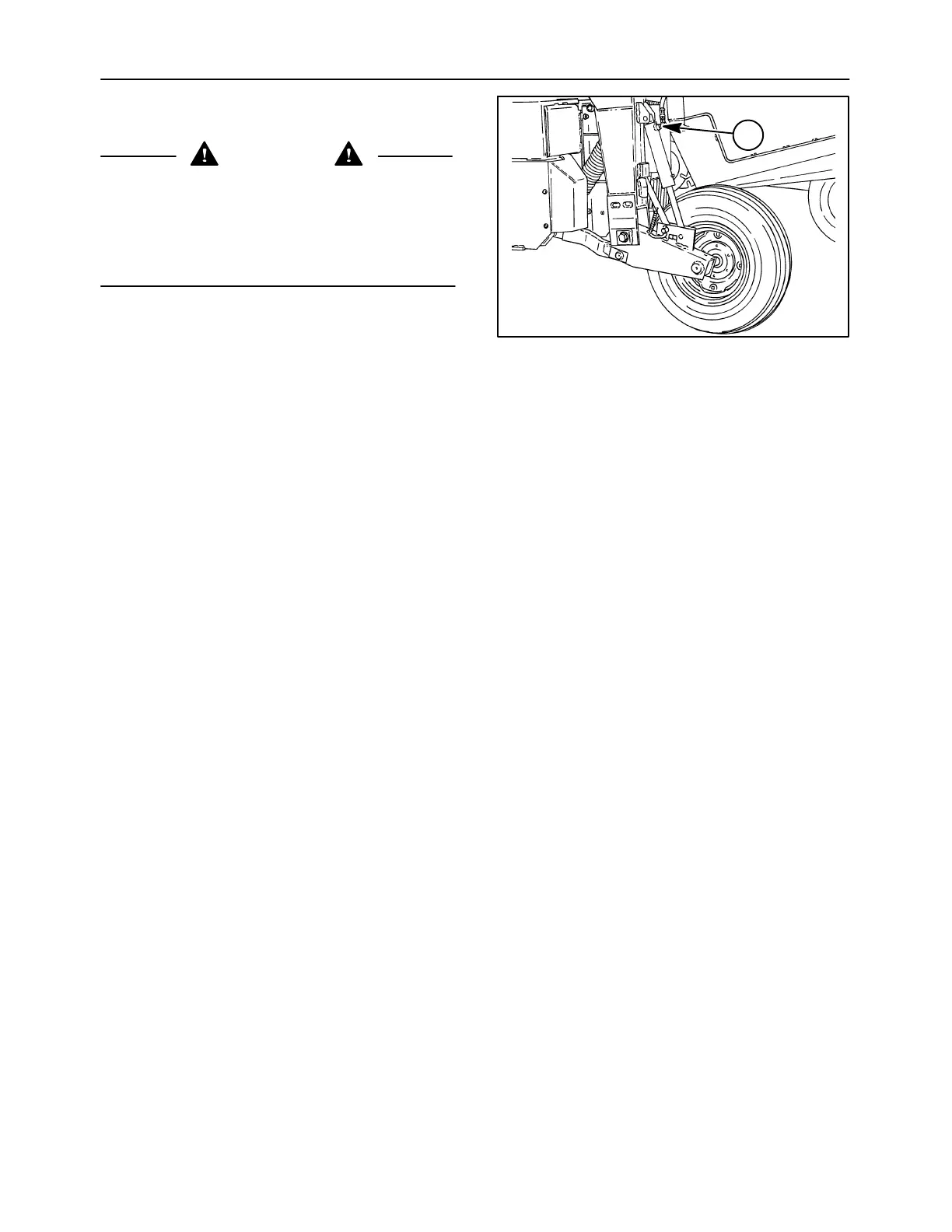

Loosen the hose swivel fitting, 1, at the upper end of

the slave cylinder.

NOTE: Use a shop rag or other shielding means for

protection from seeping oil at loosened fittings.

With the tractor engine at a low idle, move the tractor

hydraulic lever to the raise position to extend the

master lift cylinder until oil flow from the loosened

fitting is free of air. Then tighten the fitting.

IMPORTANT: If the cylinders do not extend far

enough to release the header lift locks, air remains in

the hydraulic system and must be purged. If the

header lift lock on the master cylinder side does not

release, excessive oil may be in the slave cylinder

circuit. Bleed this oil until both lock rods are engaged

on their respective stop blocks.

Raise and lower the header several times until all air

is purged from the system. Repeat the previous

steps if necessary.

19982129

1

9

Loading...

Loading...