SECTION 00 - GENERAL INFORMATION - CHAPTER 3

00-3

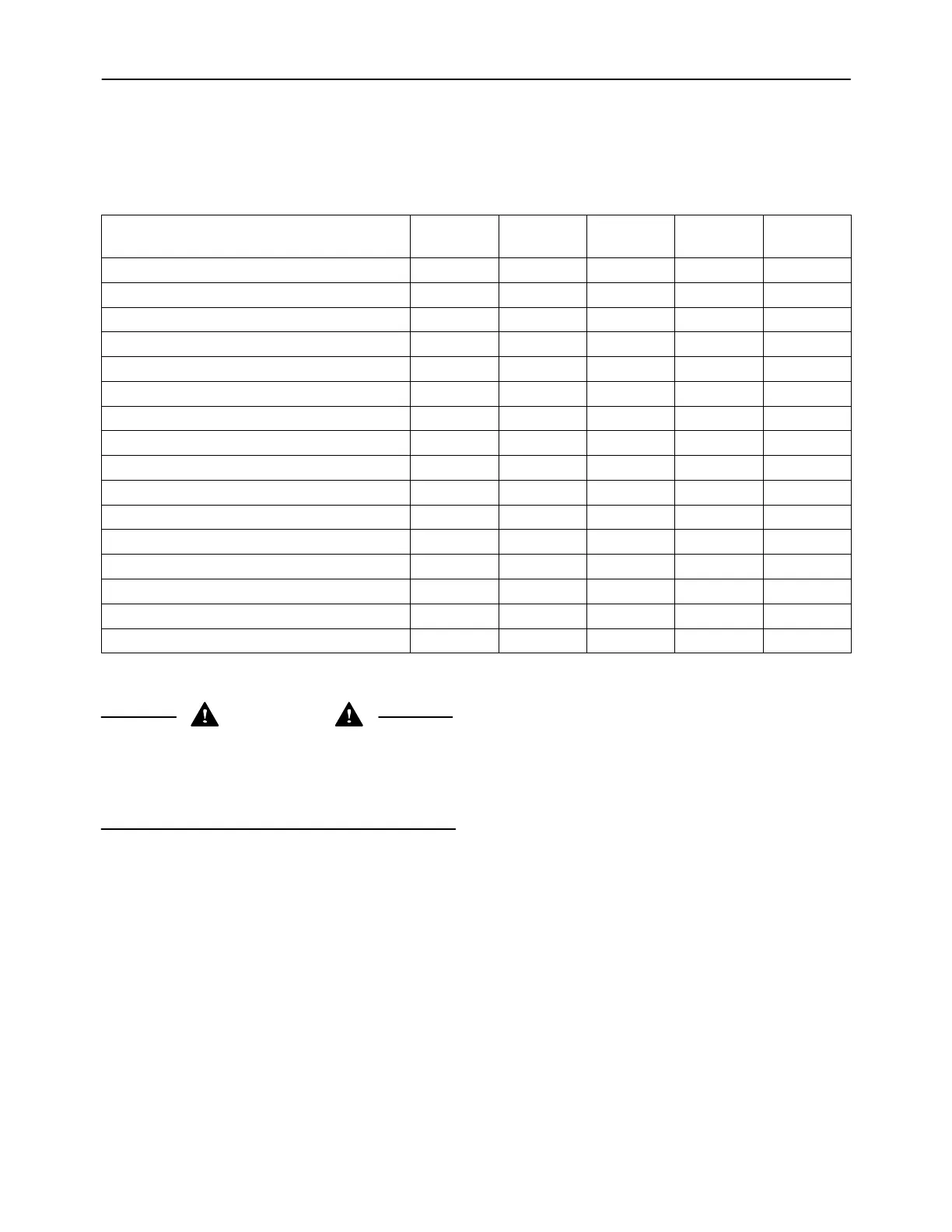

LUBRICATION SCHEDULE

NOTE: The items listed at the first 50 hours are very important. If they are not performed, it could cause early

failures of components and severely lower the life expectancy of the disc mower-conditioner.

Description

Every

8 HRS

After First

50 HRS

Every

100 HRS

Every

200 HRS

Every

400 HRS

PTO slide collar X

Primary PTO X

Secondary PTO X

Roll drive X

Cutter bar driveshaft X

Upper roll pivot arms X

Wheel arms X

Header lift arm X

Tongue pivot pin X

Cutter bar mounting bolts X

Roll pressure crank X

Step-up gearbox X X

Bevel gearbox X X

Roll drive gearbox X X

Cutter bar modules X X

Wheel bearings X

DANGER

The header should be resting on the ground or

suspended in the transport position by the

header lift locks during lubrication or mainte-

nance. Failure to comply will result in death or

serious injury.

NOTE: The machine should be checked daily for oil

leaks. Any leak should be fixed immediately.

NOTE: Clean the area around all plugs and grease

fittings prior to removing or greasing.

NOTE: All oil levels are checked with the cutter bar

level both from front to back and side to side.

GREASE FITTINGS

Grease fittings are identified in the following Figures.

Recommended lubrication intervals are listed after

each description.

NOTE: Premium grease EP-2 should be used at all

grease points.

GEARBOXES

Oil for the gearboxes and cutter bar modules is

available from your authorized dealer.

Maintain oil level using Case 135H EP (API GL 5

80W 90) gear oil or Case Gear Lube SSL (75W90

synthetic).

NOTE: Failure to use the correct specification of oil

may lead to premature failure of the gearbox

components.

IMPORTANT: The oil in all gearboxes should be

changed after the first 50 hours of use to remove any

contaminants from the break-in process.

Loading...

Loading...