SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 2

58-13

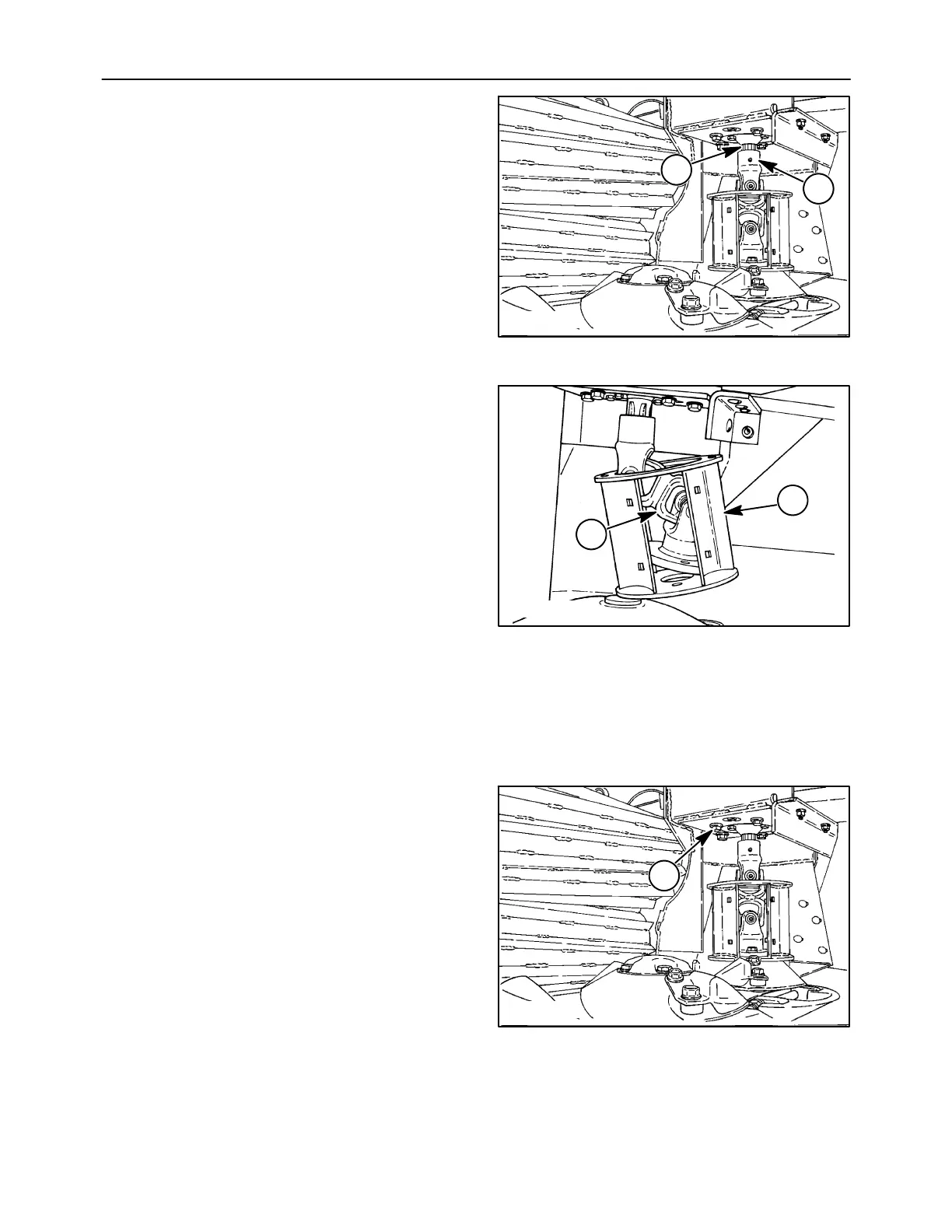

BEVEL GEARBOX - INSTALLATION

1. Set the gearbox onto the header frame, inserting

the output shaft through the hole in the frame.

IMPORTANT: The bevel gearbox is heavy and

awkward; use caution not to drop the gearbox as

personal injury or damage to the gearbox may result.

It will be necessary to install the cutter bar drive

shaft over the output shaft of the bevel gearbox

during installation; this can be done in two ways:

a. While lowering the bevel gearbox onto the

header frame, have a second person align

the cutter bar drive shaft, 1, so that it engages

on the gearbox output shaft, 2.

20011832

1

2

25

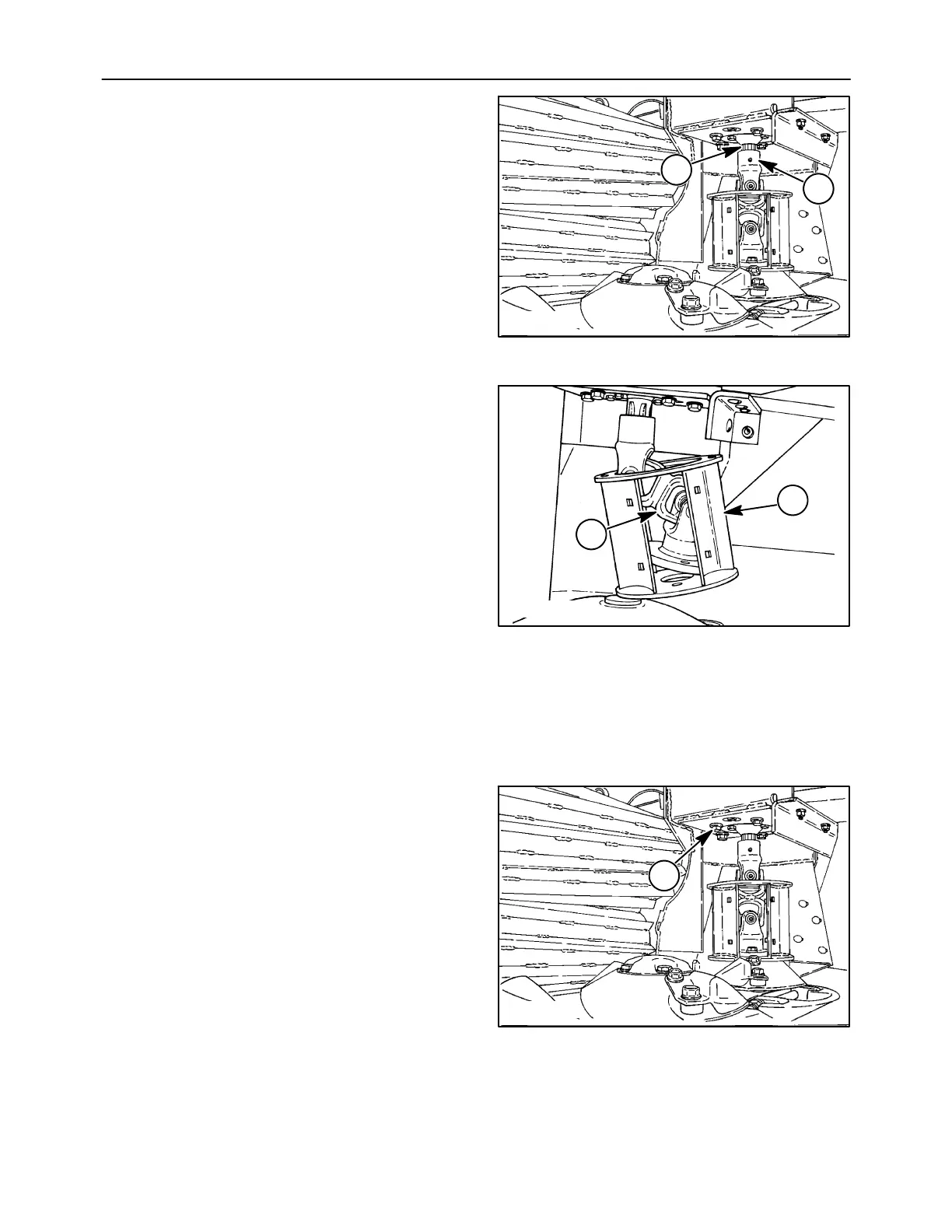

b. If gearbox is being installed by one person, it

will be easier to remove the tower, 1, and

drive shaft, 2, by removing the four 1/2″ x

1-3/4″ cap screws and hardened washers. It

will be necessary to remove the wear plates,

if equipped, from the tower to provide

additional clearance when reinstalling the

drive shaft. Install the bevel gearbox onto the

header frame, and reinstall the drive shaft

and tower by sliding the drive shaft up over

the output shaft and position onto the #1 disc.

Ensure the disc is positioned at right angles

to the #2 disc, and torque the four cap screws

to 113 N⋅m (83 ft-lb).

IMPORTANT: Reinstall the correct 1/2

″

x1-3/4

″

cap

screws and hardened washers. Use of incorrect disc

retaining hardware may cause cutter bar lock-up and

potential damage, or may prevent proper retention of

#1 disc.

50011833

1

2

26

2. Install the five cap screws, 1, and flat washers to

retain the gearbox to the header frame, and

torque to 113 N⋅m (83 ft-lb).

20011832

1

27

Loading...

Loading...