SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 3

58-8

16

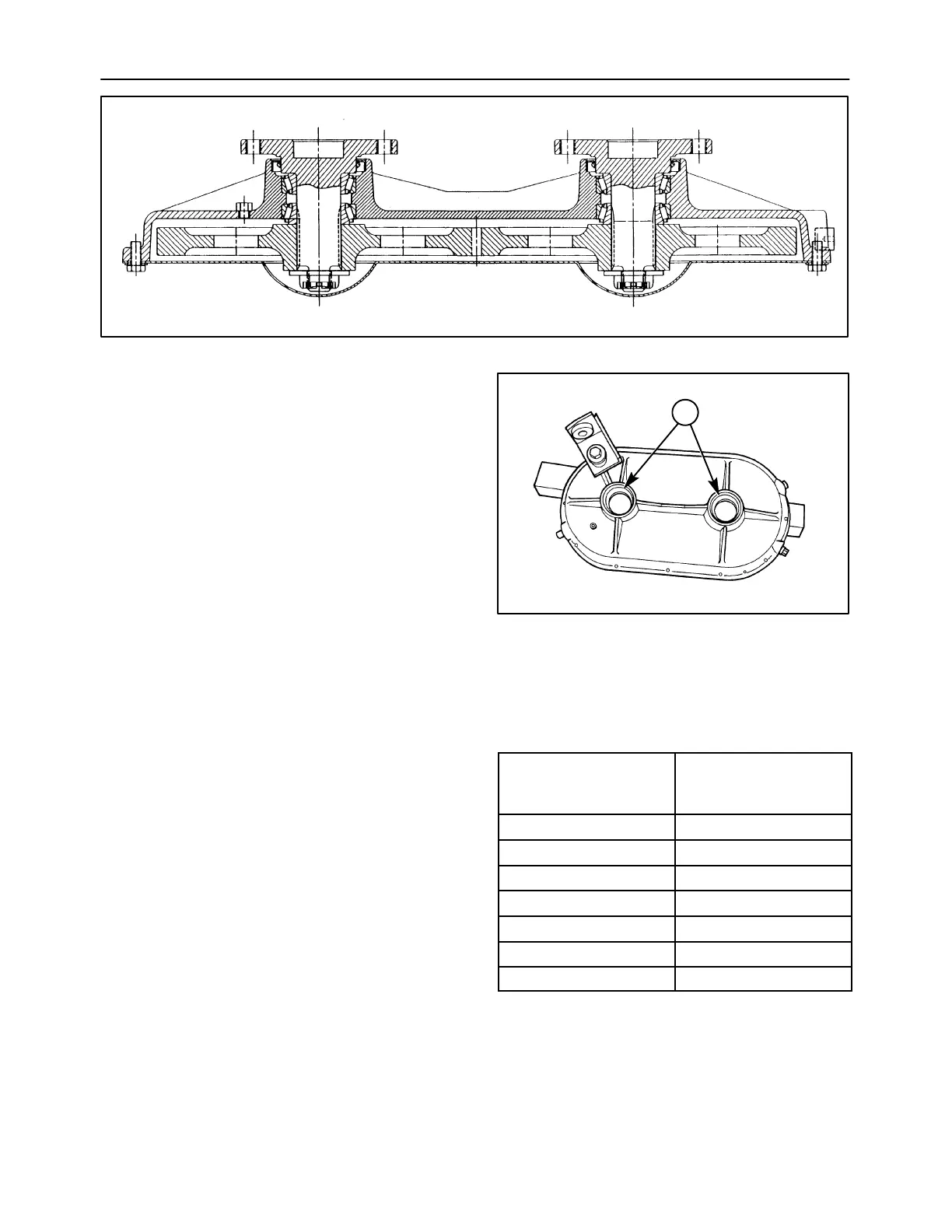

CONDITIONER ROLL GEARBOX -

ASSEMBLY

1. Thoroughly clean the gearbox housing, taking

care to remove all old sealant on cover mounting

flange. Install bearing cups into housing with the

cups facing outwards from bore. Firmly seat

bearing cups against shoulders in housing.

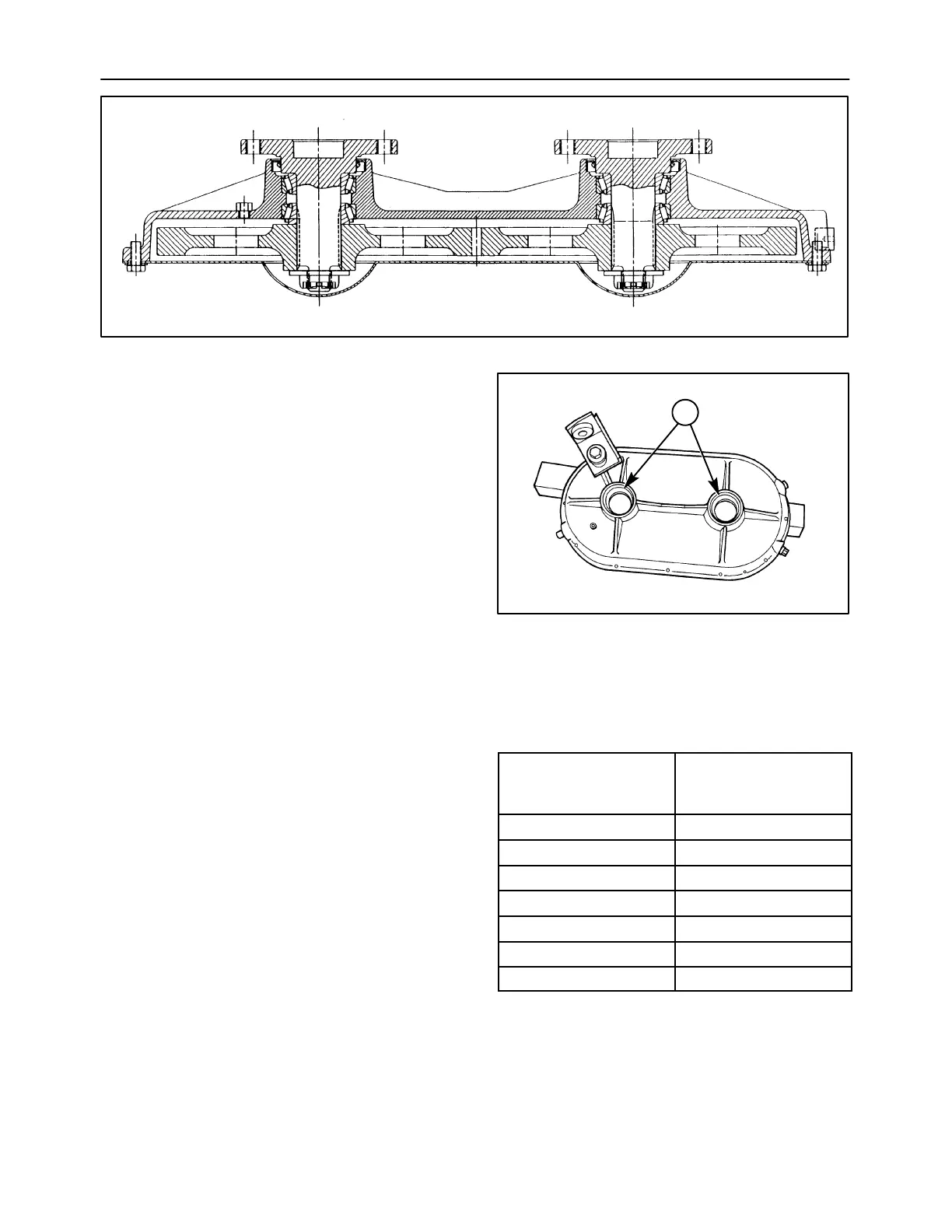

2. Install the shaft seal, 1, into housing so that outer

face of seal is flush with outer face of the housing.

3. Pack a new bearing cone with grease, and press

it onto shaft, seating it against the shoulder.

4. Apply grease to the lip on the shaft seal. Install

the shaft assembly through seal, taking care not

to damage it. Pack a new bearing cone with

grease, and install it over the shaft. Press it down

into bearing cup until the bearing cone is almost

fully seated.

1411/8-4

1

17

5. Install a gear onto shaft splines, and install a

hardened washer and castellated nut onto shaft.

Tighten the nut to seat the bearing cone into the

cup and obtain 0.45 -- 1.13 N⋅m(4--10in-lb)

rolling torque on shaft.

6. Install other shaft in same manner as the first.

The shaft and gear do not need to be indexed, or

timed to one another. Tighten the nut to seat the

bearing and set the rolling torque on the second

shaft to 0.45 -- 1.13 N⋅m (4 -- 10 in-lb) plus the

rolling torque value obtained on the first shaft, as

per the chart at right.

First Shaft

Second Shaft

o

ng

orque

Nám(in-lb)

o

ng

orque

Nám(in-lb)

0.45 (4) 0.9 -- 1.58 (8 -- 14)

0.57 (5) 1.02 -- 1.7 (9 -- 15)

0.68 (6) 1.13 -- 1.8 (10 -- 16)

0.79 (7) 1.24 --1.9 (11 --17)

0.9 (8) 1.36 -- 2.03 (12 -- 18)

1.02 (9) 1.47 -- 2.15 (13 -- 19)

1.13 (10) 1.58 -- 2.26 (14 -- 20)

Loading...

Loading...