SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 1

58-5

DISCS

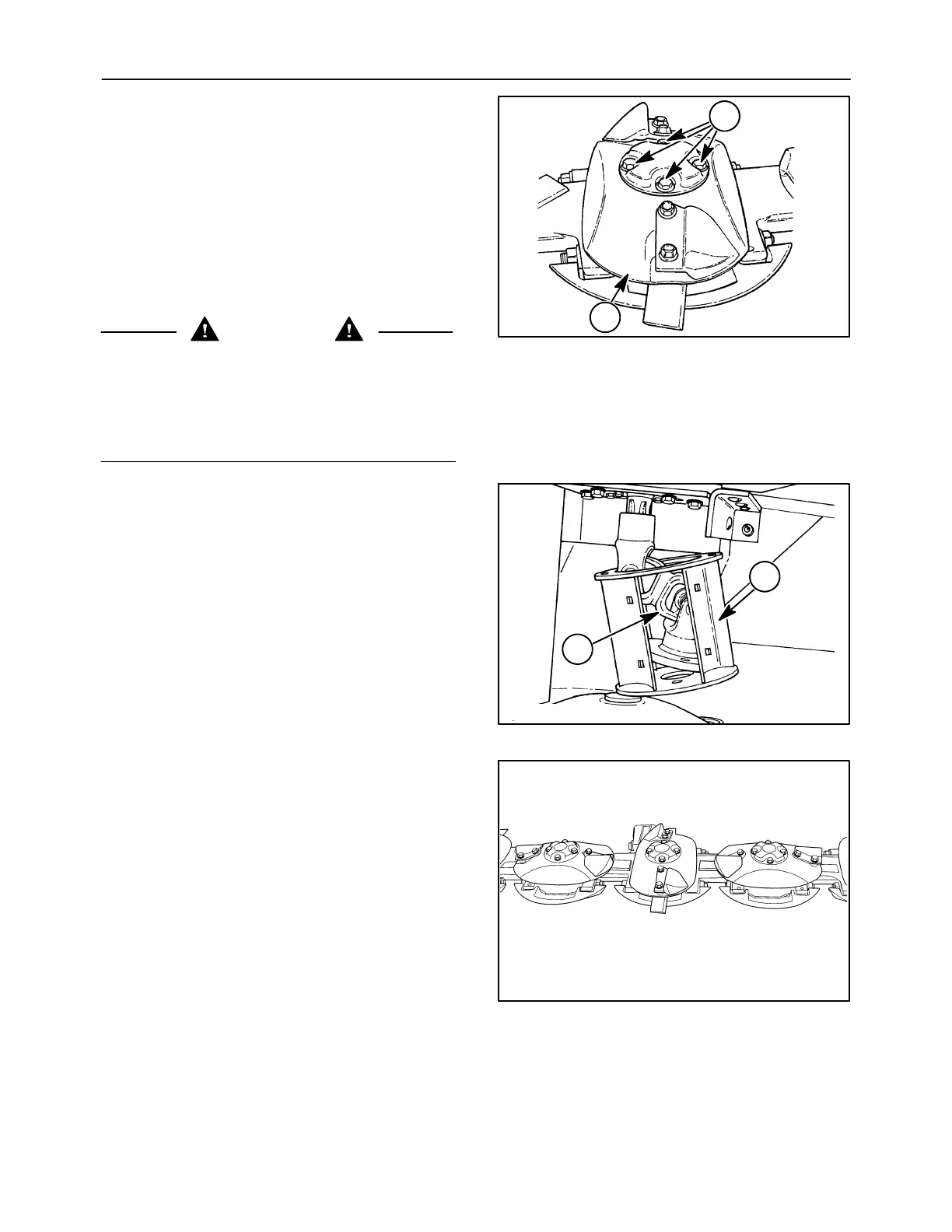

Each time knives are replaced or turned, check the

discs for damage and wear. If a disc is bent or

cracked, replace it. When the leading edge, 1, of the

disc wears thin, it can be used on an opposite rotating

module to utilize the second face.

IMPORTANT: Do not make weld repairs to the discs,

as this will affect disc strength and balance.

Remove discs by removing four bolts at 2.

WARNING

Disengage the PTO, turn off the tractor engine

and remove the key. Wait for all movement to

stop before leaving operator’s position. Never

adjust, lubricate, clean or unplug machine with

the engine running. Failure to comply could

result in death or serious injury.

2--48

1

2

9

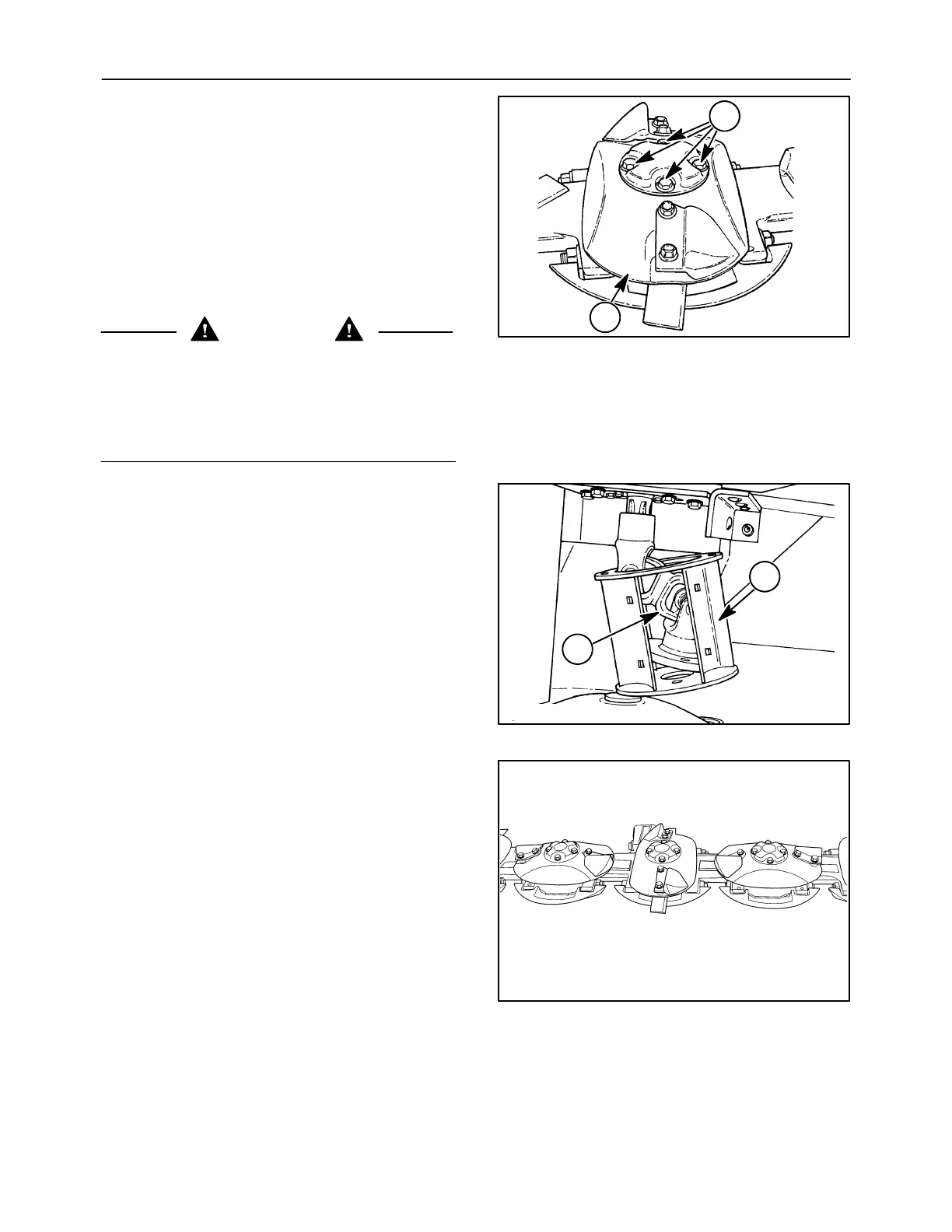

Discs with towers can also be removed. On the right

side, remove the four retaining bolts, and remove the

tower and disc.

On the left side, it will be necessary to remove the

wear plates, if equipped, from the tower, 1, to provide

additional clearance. Remove the four retaining

bolts, and slide the tower, 1, and drive shaft, 2,

upwards and to the side in order to remove the disc.

50011833

1

2

10

Reinstall discs at right angles to each other as

shown. Position the end towers so that the notches

in tower base align with the slots in the disc. Be sure

the correct hardware is installed as follows:

Discs w/caps: 1/2″ x1″ cap screws.......

cupped lock washers

Right end disc

& tower: 1/2″ x1-1/4″ cap screws...........

thick hardened washers

Left end disc, tower

& drive shaft: 1/2″ x1-3/4″ cap screws.......

thick hardened washers

IMPORTANT: Use of incorrect disc retaining

hardware may cause cutter bar lock-up and potential

damage, or may prevent proper retention of discs.

Torque retaining bolts to 113 N⋅m (83 ft-lb).

NOTE: Do not overtighten as bolts may yield.

19981908

11

Loading...

Loading...