SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 3

58-12

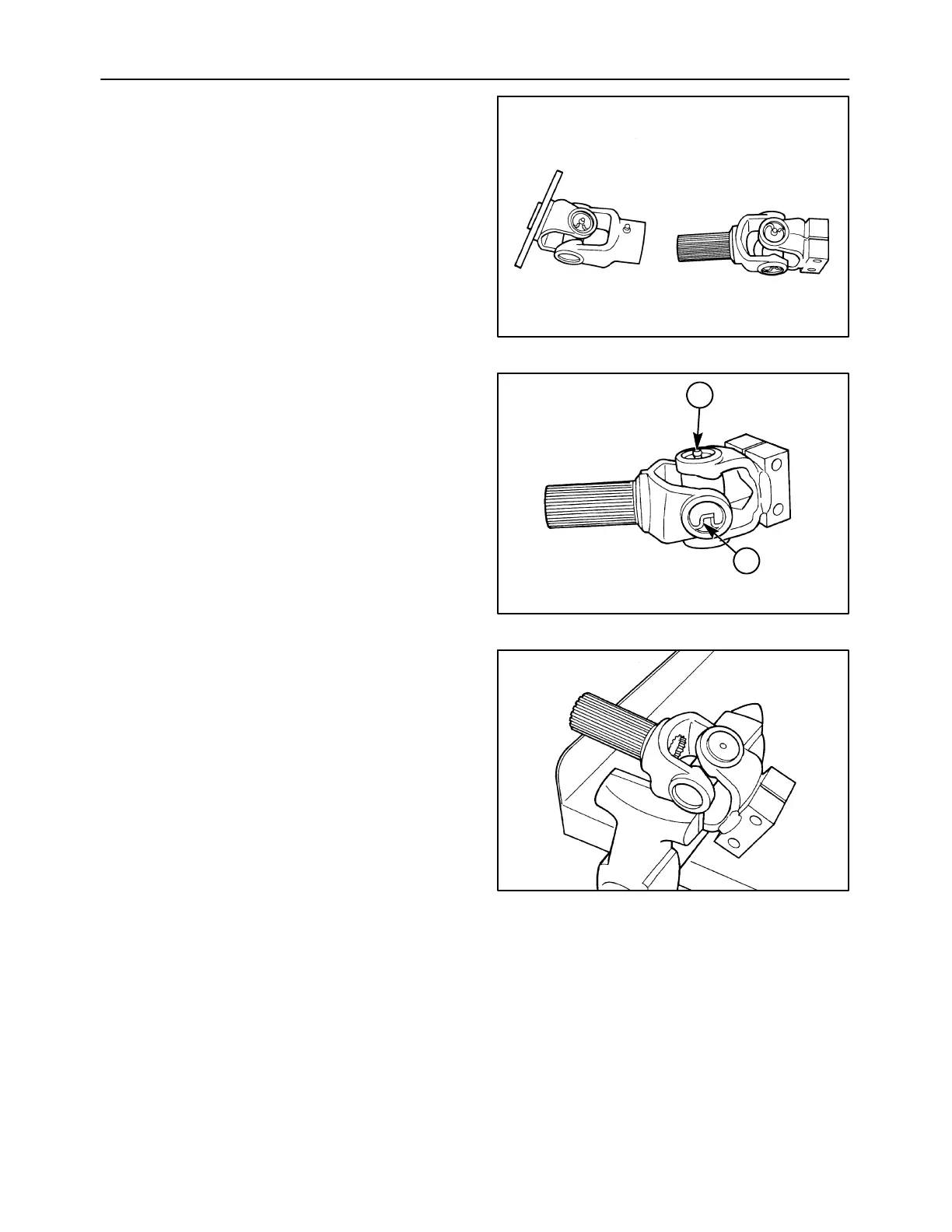

2. The drive shaft can be slid apart, and each end

serviced separately.

1411/8-5

27

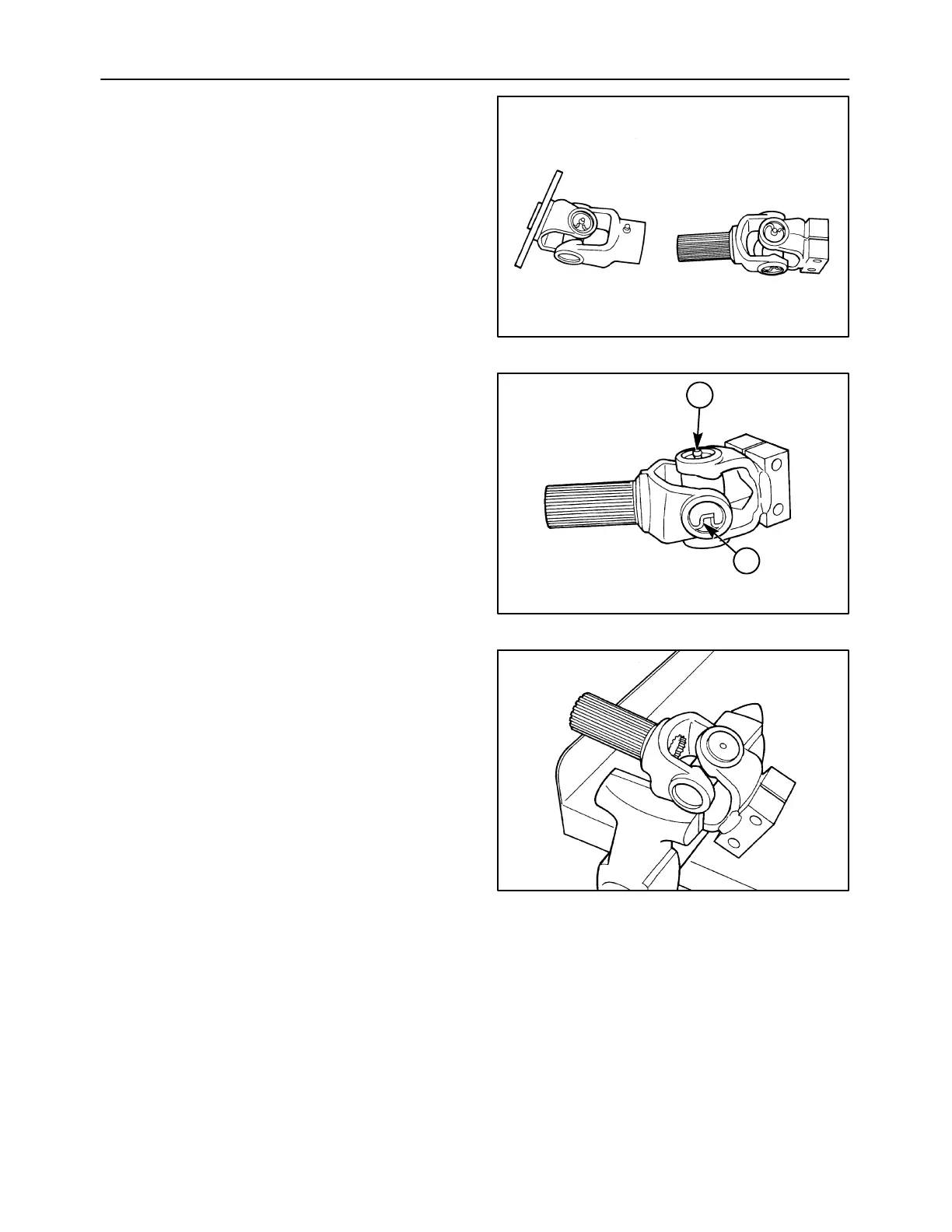

3. Remove the internal snap rings, 1, from the

U-joint using pliers. Remove the grease zerk, 2,

from one bearing cup before the snap ring may

be removed.

NOTE: The grease zerk, 2, is oriented to line up with

other grease zerks on the driveline. Note the

positioning of the grease zerk prior to removal.

1411/8-6

1

2

28

4. Position the joint in an open vise, with each ear

of one yoke supported by a vise jaw.

5. With a soft hammer or mallet, strike the top ear

of the unsupported yoke. This will drive the top

bearing outward approx. 8 mm (1/4″).

IMPORTANT: Do not use a hard faced hammer, as

this may damage the edge of the bearing cup bore in

the yoke or the snap ring groove area, causing the

bearing cup to hang-up or seize in the yoke.

6. Pull the bearing out of the yoke ear. If necessary,

grip the loosened bearing in a vise, and drive the

yoke off the bearing by striking yoke ear with the

soft-faced hammer or mallet.

7. This same procedure should be followed to

remove the bearing directly opposite the one just

removed, after which the yoke itself may be

removed.

1411/8-7

29

Loading...

Loading...