SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 3

58-36

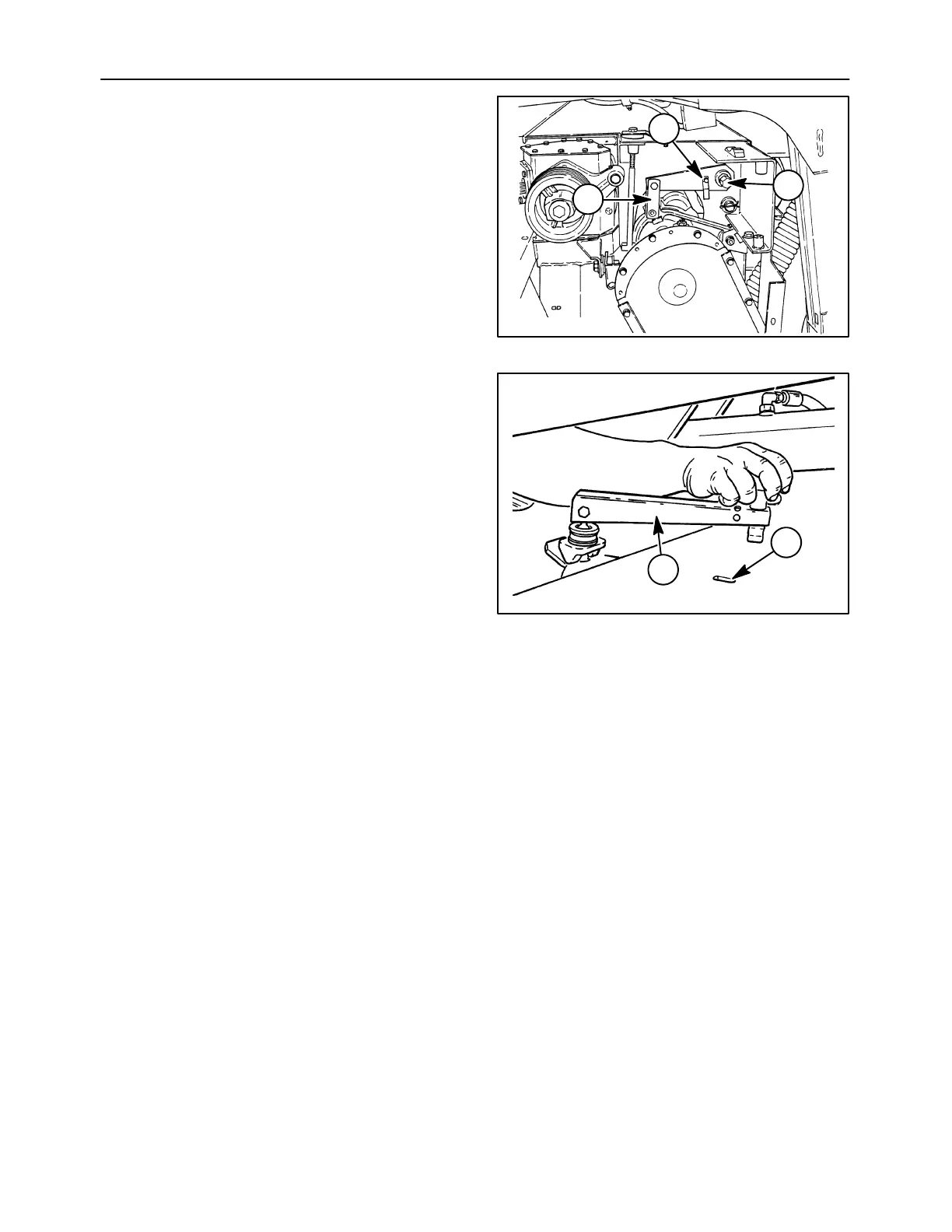

2. Apply a permanent lubricant to the hex bores of

the adjusting tube and the tension arm, 1. Apply

permanent lubricant to the ends of the torsion

bar, and slide it through the tension arm until the

inner end engages in the adjusting tube.

Continue to slide the torsion bar in until it is fully

seated in the tension arm. Swing the retaining

clip, 2, up over the end of the torsion bar and

tighten the cap screw. Lift the tension arm up until

the tension straps, 3, are aligned with the

bushing in the upper roll pivot arm. Install the cap

screw and tighten securely.

A5044-16

1

2

3

97

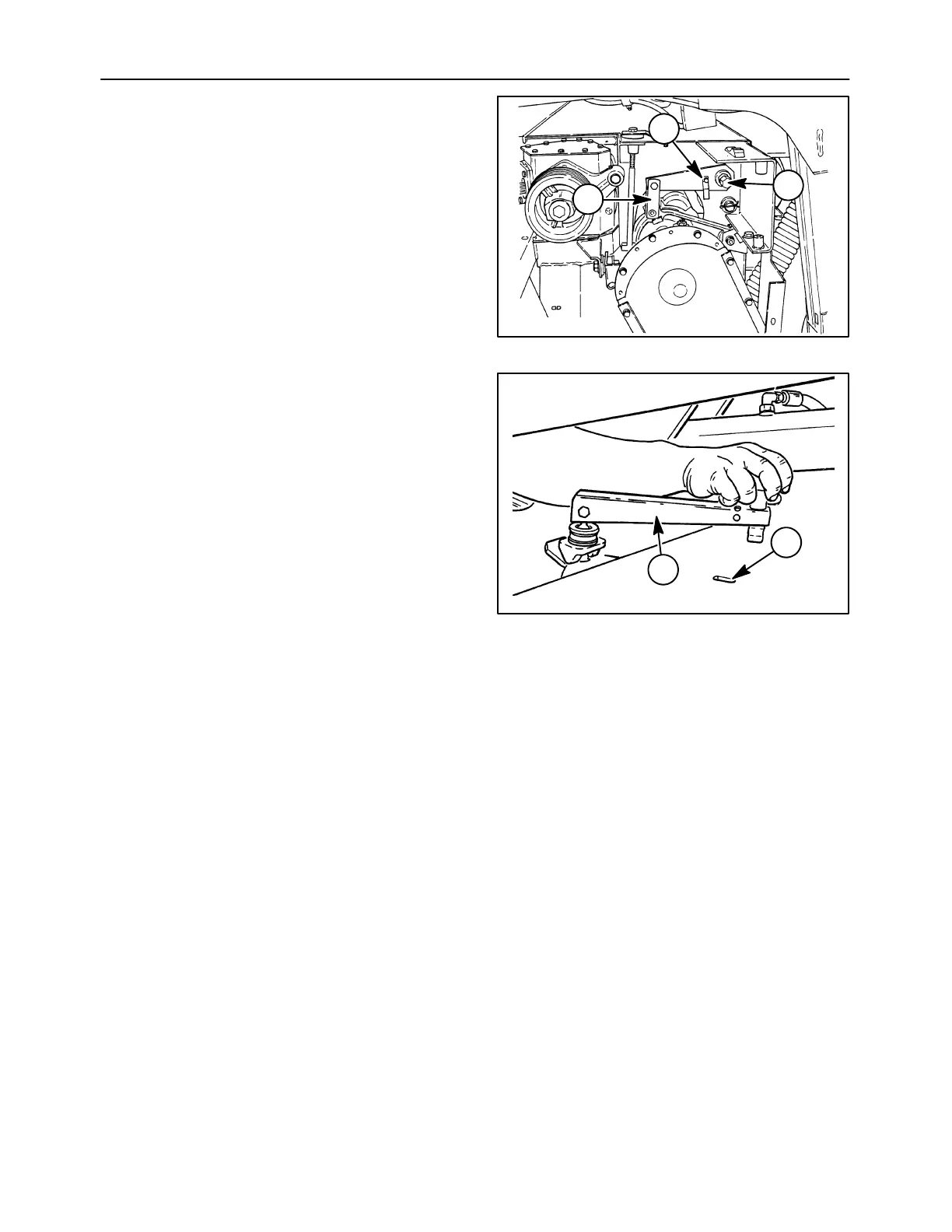

3. Adjust the roll tension to a starting point by

rotating the adjusting handle, 1, clockwise until

all slack is taken up, and then apply eight

additional turns. Reengage the retaining clip in

the notch, 2, in the header frame.

A3658-3

1

2

98

Loading...

Loading...