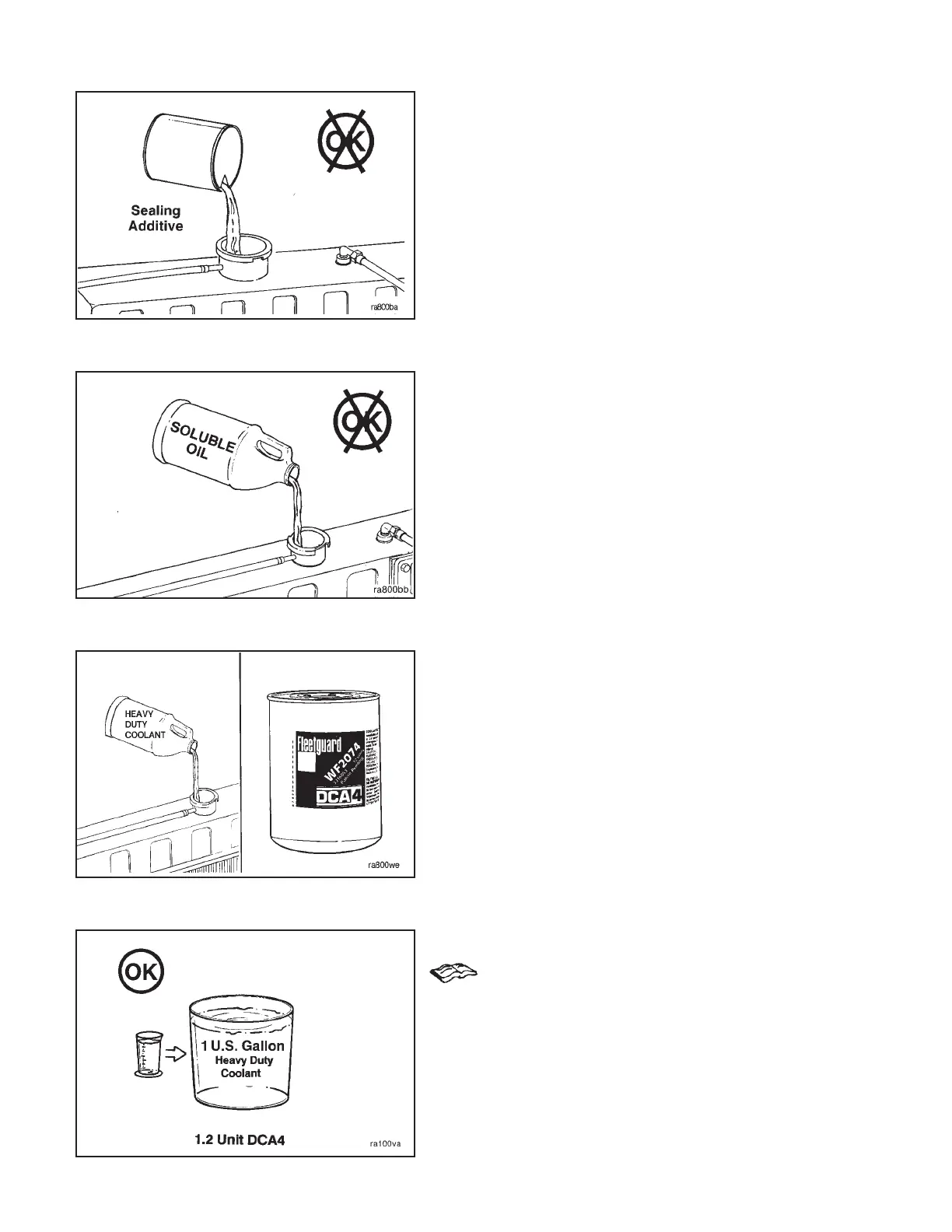

Cooling System Sealing Additives

(1-03)

Do not use sealing additives in the cooling systems.

Using sealing additives will cause the following problems:

• Buildup in coolant low flow areas.

• Clogged coolant filters.

• Plugged radiator and oil cooler.

Cooling System Soluble Oils (1-04)

Do not use soluble oils in the cooling systems. The use

of soluble oils will:

• allow cylinder liner pitting,

• corrode brass and copper,

• damage heat transfer surfaces, and

• damage seals and hoses.

Coolant Additive Requirement (1-05)

Supplemental Coolant Additives (DCA4), or equivalent,

are required to protect the cooling system from fouling,

solder blooming, and general corrosion. The coolant filter

is required to protect the coolant system from abrasive

materials, debris, and precipitated coolant additives.

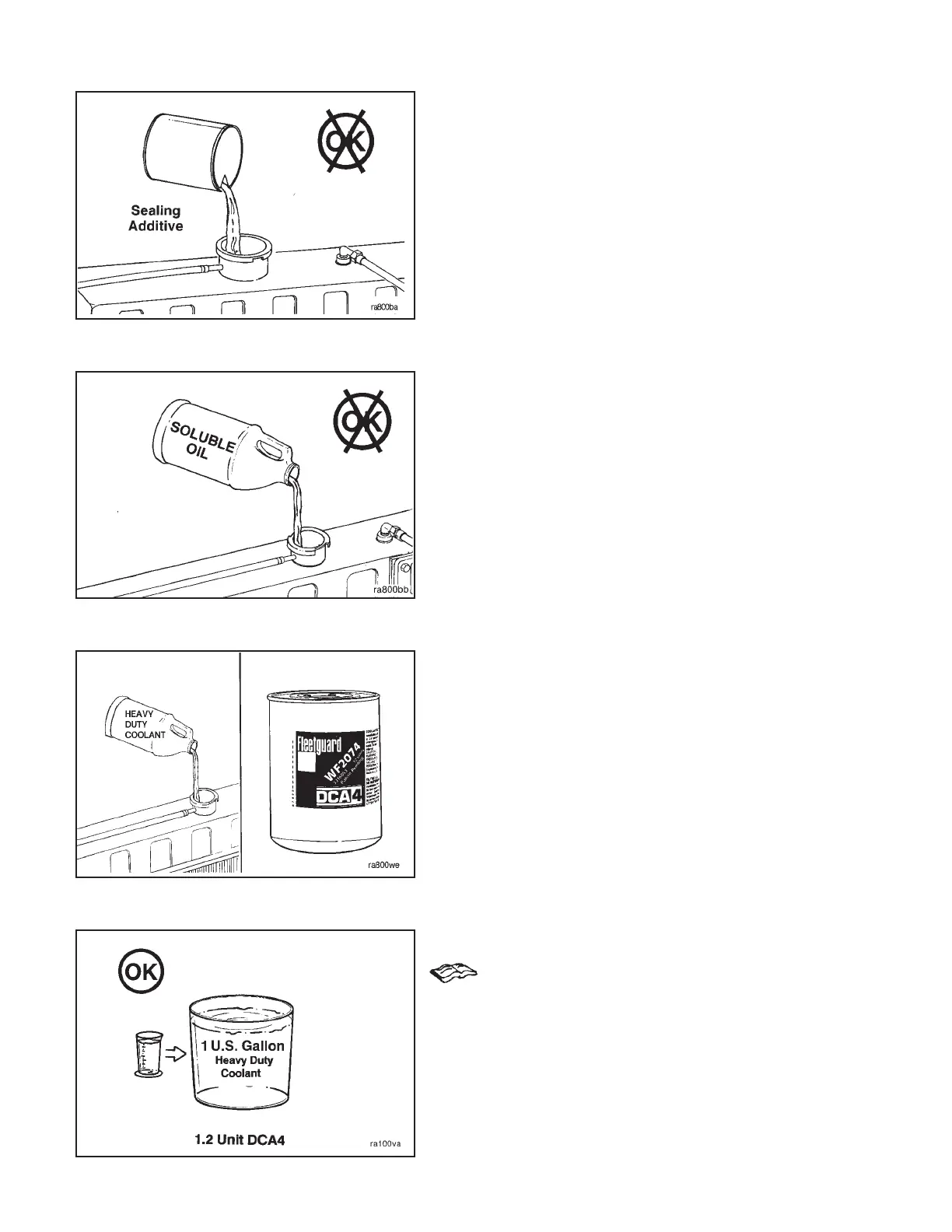

NOTE: Cummins Engine Company requires that a service

filter be used and SCA liquid added when the coolant is

changed or a significant (more than 50 percent) coolant loss

occurs. A service filter must be used during the normal oil

change interval (refer to the Operation and Maintenance

Manual).

Diesel Coolant Additives (or equivalent) are used to pre-

vent liner pitting, corrosion and scale deposits in the

cooling system.

Cooling System Sealing Additives (1-03) Section 1 - Cooling System

N14Page 1-14

Loading...

Loading...