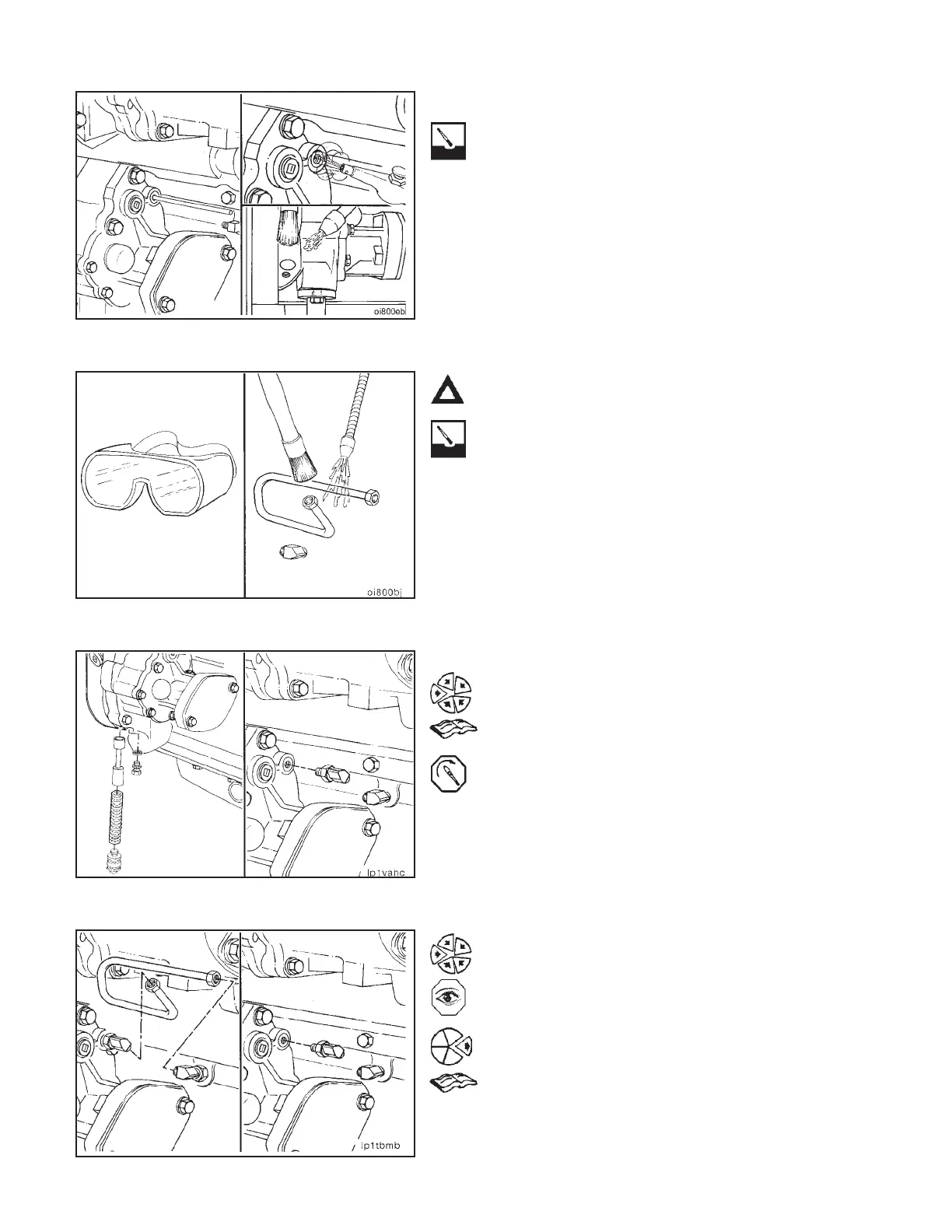

Cleaning

Use an acetylene torch tip cleaner or equivalent that is 1.0

mm [0.040-inch] or less in diameter to clean the orifice.

NOTE: The diameter of the orifice is 1.0 mm [0.040-inch]. Do

not attempt to drill out the orifice or use a larger diameter

wire to clean the orifice.

Use solvent and an air solvent gun to wash the debris

from the orifice and the pressure regulator bore in the

lubricating oil pump.

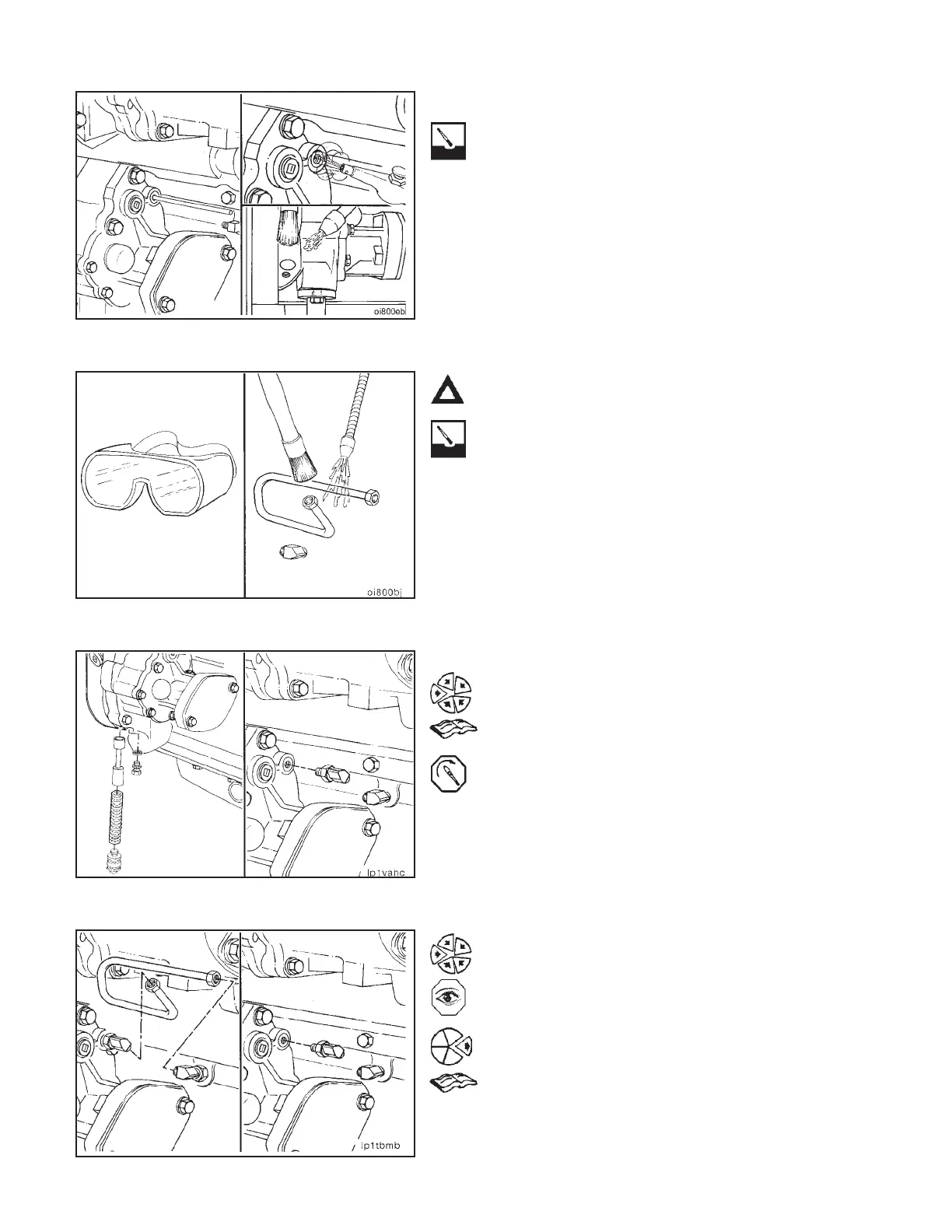

Caution: Wear safety goggles when using an air solvent

gun to prevent possible injury.

Clean the inside of the signal line and the 7/16-20 UNF

straight thread with o-ring seal adapter with solvent and

an air solvent gun.

Installation

Install the main oil pressure regulator. Refer to Procedure

2-15.

Install the 7/16-20 UNF straight thread with o-ring seal

adapter, in the lubricating oil pump front cover.

Torque Value: 17 N•m [150 in-lb]

Install the DFC signal line.

Operate the engine until the water temperature reaches

82°C [180°F], and check the oil pressure.

NOTE: If the oil pressure problem still exists or occurs again

soon after the above procedure has been completed, re-

move the lubricating oil pump for disassembly and a thor-

ough cleaning. Refer to Procedure 2-13.

Lubricating Oil Pump Signal Line Orifice (In Chassis) (2-17) Section 2 - Lubricating System

N14Page 2-42

Loading...

Loading...