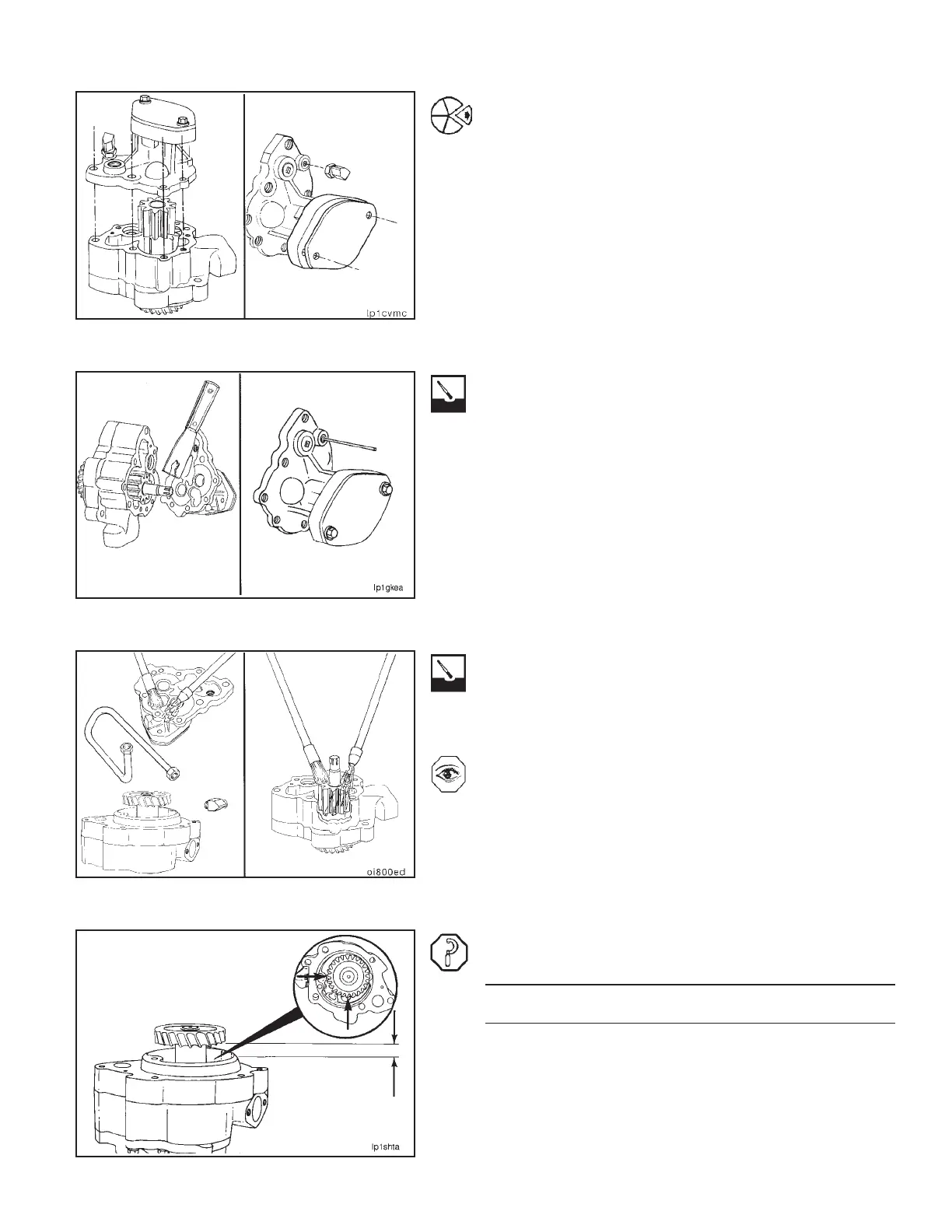

Remove the lubricating oil pump front cover and the

lubricating oil pump driven gear.

Remove the 7/16-20 UNF straight thread with o-ring seal

adapter and the power steering pump mounting flange

cover from the lubricating oil pump cover.

Clean the gasket material from the lubricating oil pump

body and cover.

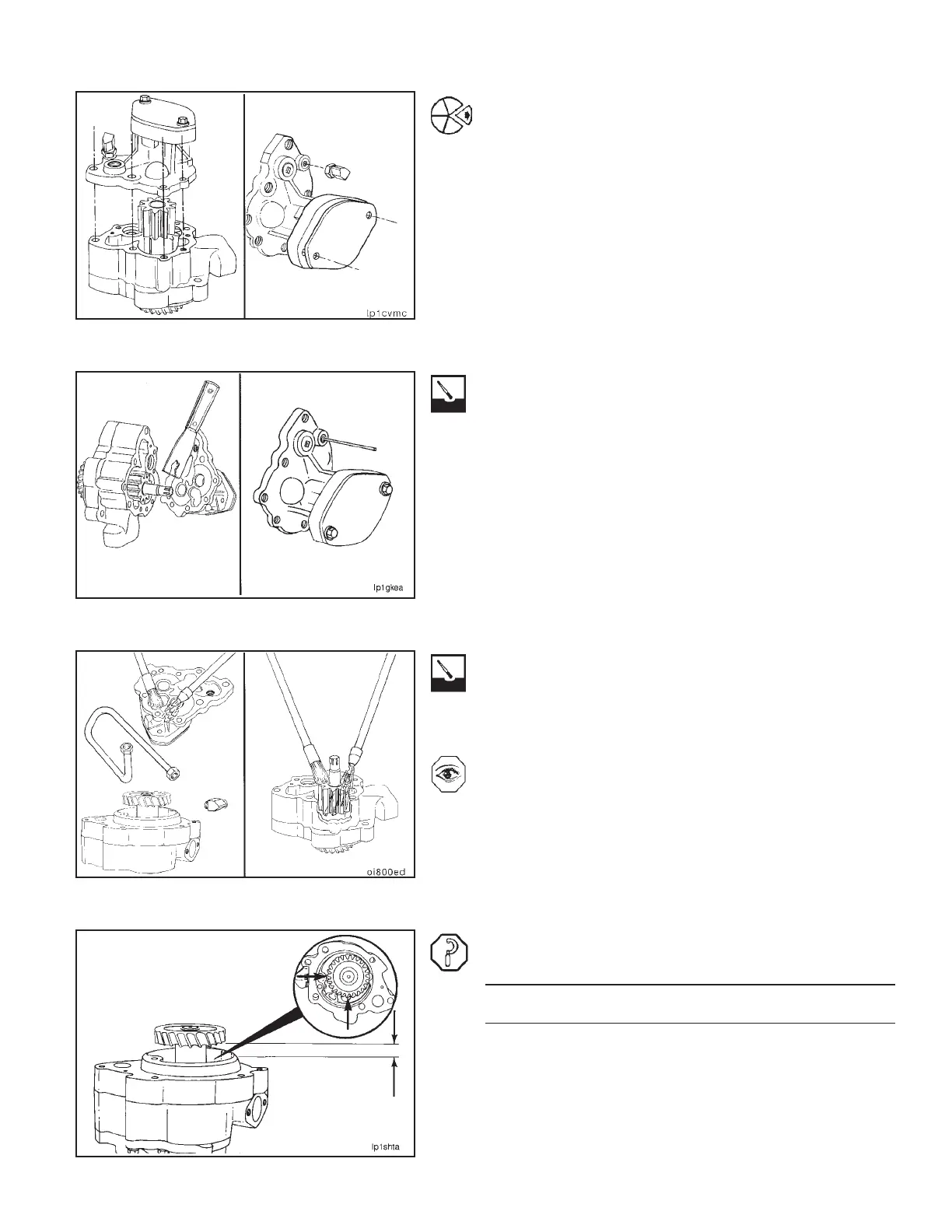

Use an acetylene torch tip cleaner or equivalent that is 1.0

mm [0.040-inch] or less in diameter to clean the orifice.

NOTE: The diameter of the orifice is 1.0 mm [0.040-inch]. Do

not attempt to drill out the orifice or use a larger diameter

wire to clean the orifice.

Use solvent and an air solvent gun to clean the signal line,

the 7/16-20 UNF straight thread with o-ring seal adapter,

the lubricating oil pump cover, and the body. Hold the

driven gear off of the lubricating oil pump body when

cleaning the gear bore area.

Dry with compressed air.

Inspect the gears for freedom of rotation, and cracked or

broken teeth.

Inspect the bushings for excessive wear or discoloration

due to overheating or seizure to the shaft.

Use depth calipers or dial indicator to measure the drive

shaft end clearance in two locations 90 degrees apart.

Drive Shaft End Clearance

mm in

0.051 MIN 0.002

0.203 MAX 0.008

Rebuild the lubricating oil pump if the driveshaft end

clearance does not meet specifications. Refer to the N14

Engine Shop Manual, Bulletin No. 3810487.

Lubricating Oil Pump (2-13) Section 2 - Lubricating System

N14Page 2-32

Loading...

Loading...