The air flow piping requires 4 inch I.D. aluminized steel

piping. The flow circuit must have as few bends as pos-

sible maximizing the length of straight sections. How-

ever, when bends are required, use long elbows. Do not

use mitered elbows, or anything that changes the air flow

direction quickly. To reduce intake air restriction, air flow

direction changes must occur gradually.

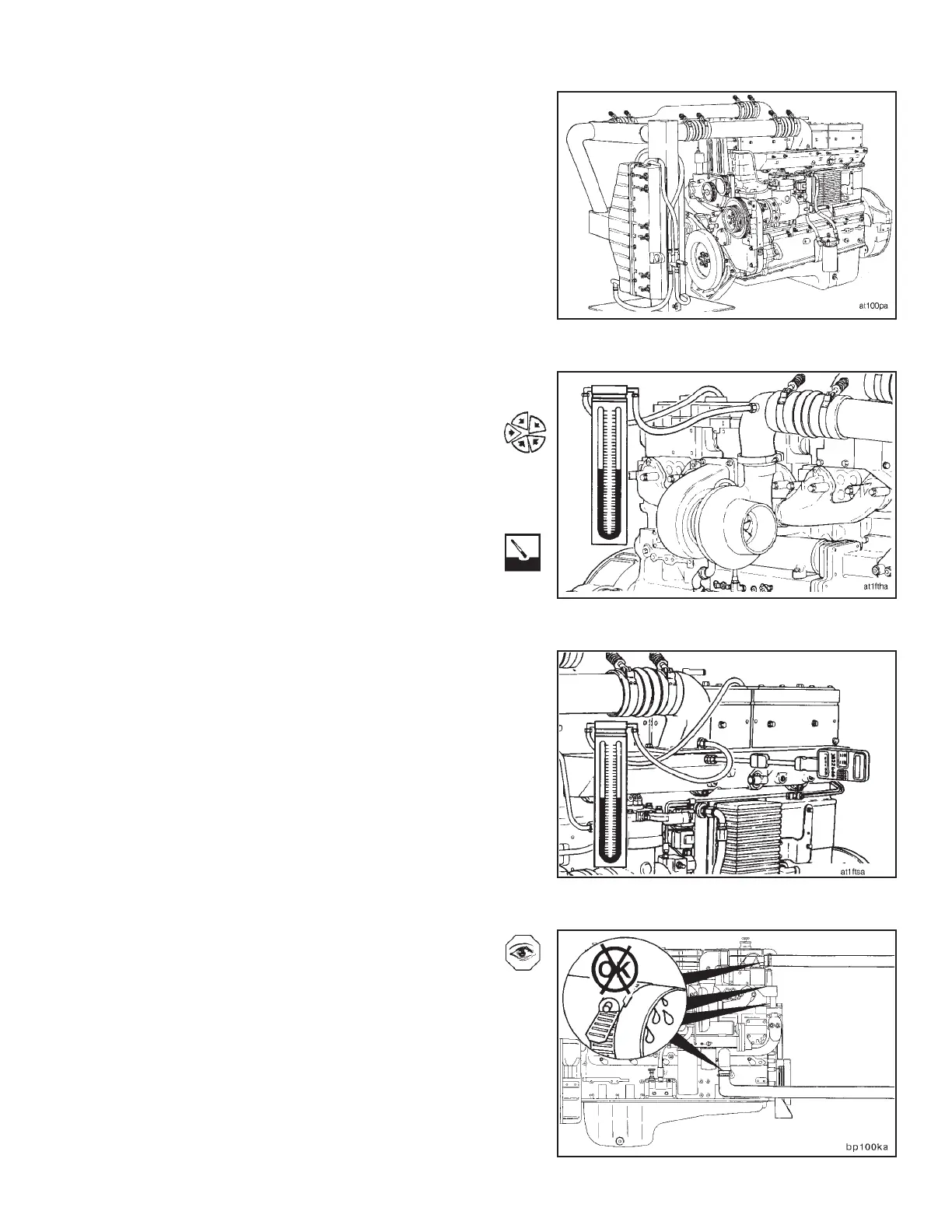

During engine test monitor the pressure drop through the

remote aftercooler. Install one end of a manometer to the

Compuchek fitting in the turbocharger compressor outlet

elbow. Install the other end of the manometer to the

Compuchek™ fitting in the intake manifold. Although less

accurate than a manometer, two individually calibrated

press (in Hg) gauges can be used to monitor pressure

drop.

The pressure drop between these two locations must not

be greater than 102 mm Hg [4 in Hg]. If the pressure drop

is greater than 102 mm [4 in Hg], check the remote

aftercoolers and air flow piping for plugging. Clean and

replace if necessary.

During engine test, also monitor intake manifold temper-

ature. Install a thermocouple (Fluke) in the 1/2 inch pipe

tap in the intake manifold. The intake air heats up as it

passes through the intake manifold so the temperature

must be measured as close to the intake manifold elbow

as possible.

If the intake manifold temperature exceeds 66°C [150°F]

during the test, make sure that there is an ample supply

of clean cool water flowing through the aftercoolers. Un-

der no circumstances must the intake air temperature be

allowed to exceed 77°C [170°F].

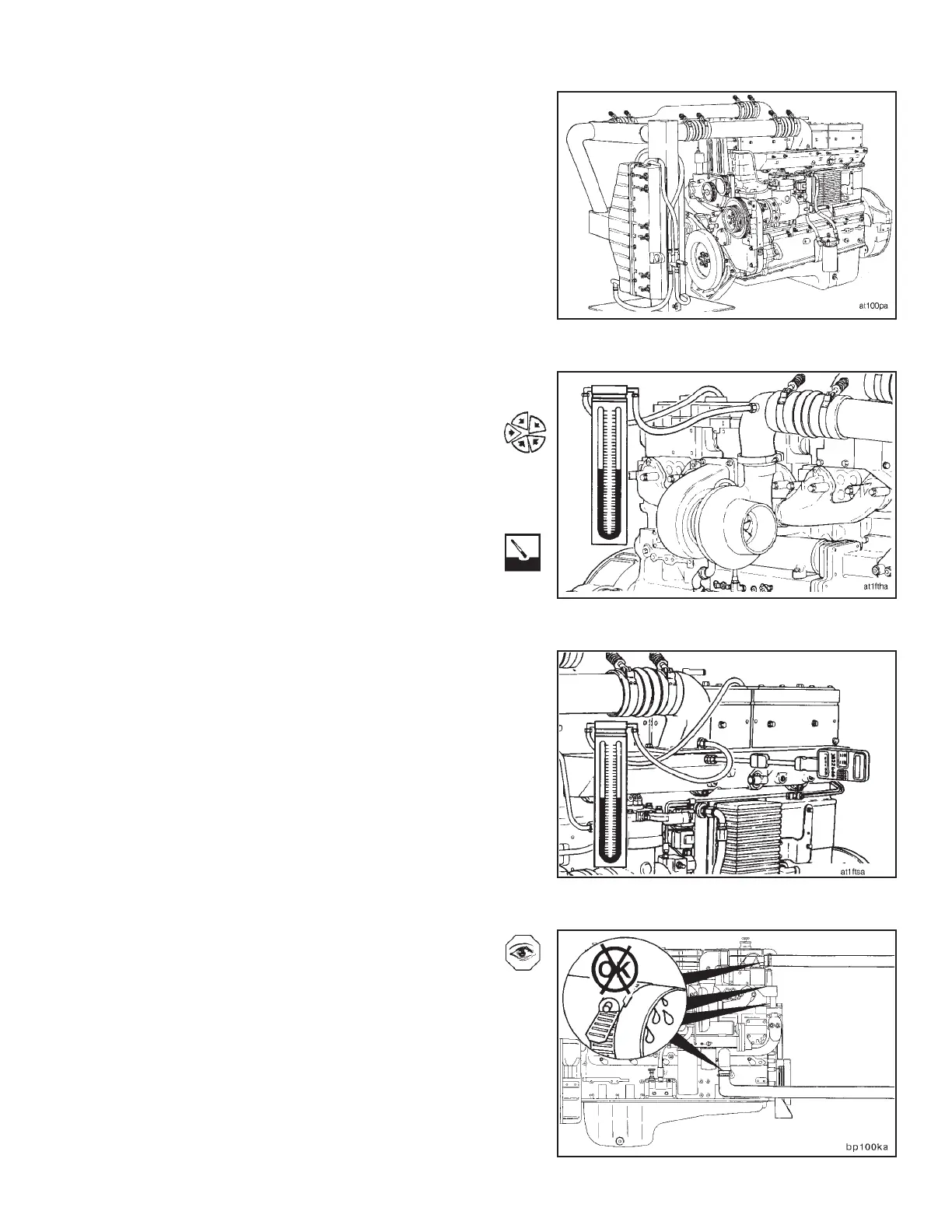

Visually inspect the engine for coolant leaks.

Repair all leaks found.

Engine Testing Engine Dynamometer - Install Engine (8-01)

N14 Page 8-11

Loading...

Loading...