If a sudden increase in blowby occurs, or if blowby ex-

ceeds the maximum allowable limit during any run-in,

return to the previous step and continue the run-in. If

blowby does not reach an acceptable level during the

next step, discontinue the run-in and determine the cause.

Do not proceed to the next step until a steady, acceptable

blowby reading is obtained.

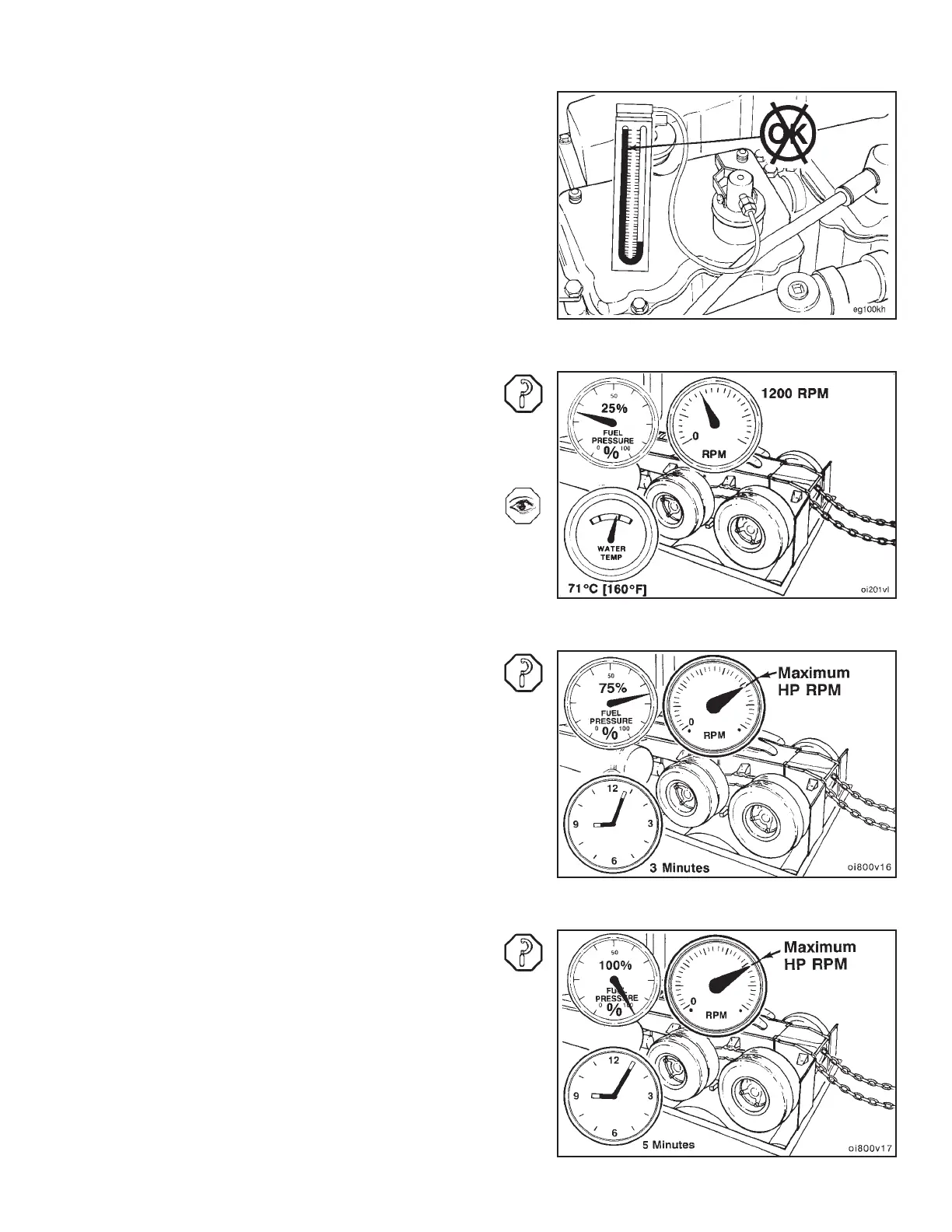

NOTE: Blowby must be measured by using Service Tool,

Part No. 3375150 or 3822566 with manometer, Part No.

ST-1111-3, or equivalent. Service Tool, Part No. 3375150,

as shown, utilizes a chamfered 7.67 mm [0.302 in] orifice.

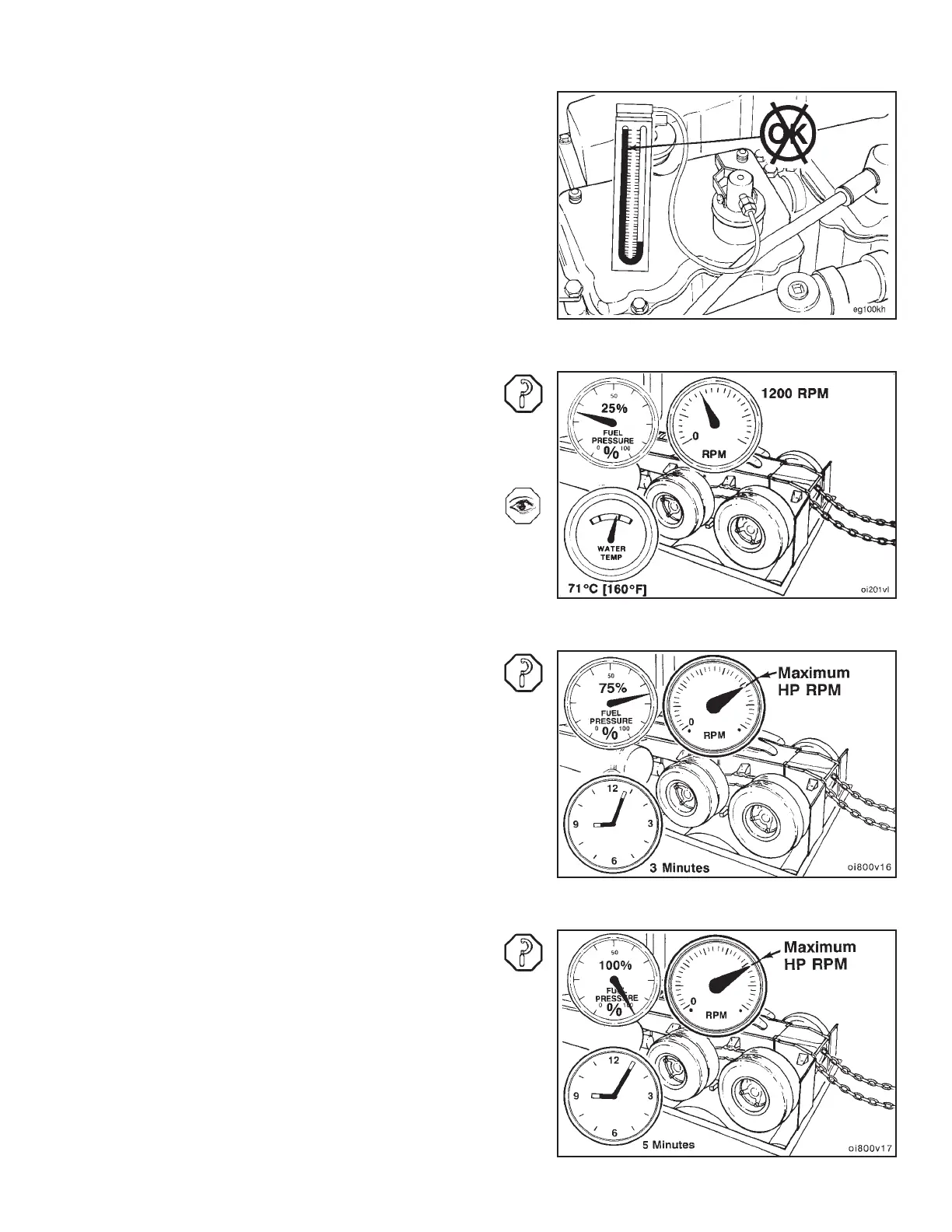

Move the throttle to obtain 1200 RPM engine speed, and

apply a test load sufficient to develop 25 percent rated

fuel pressure or 25 percent fuel rate on CELECT™ en-

gines.

Operate the engine at this speed and load level until the

coolant temperature reaches 71°C [160°F].

Check all gauges and record the data.

Operate the engine at maximum horsepower RPM and 75

percent of rated fuel pressure or 75 percent fuel rate on

CELECT™ engines for 3 minutes. Check the gauges, and

record the readings.

NOTE: Do not proceed to the next step until a steady,

acceptable blowby reading is obtained.

Operate the engine at maximum horsepower RPM and

Advertised Horsepower with a wide open throttle, for 5

minutes. Check the gauges, and record the readings.

Engine Testing Engine Run-In Procedure - Chassis Dynamometer (8-07)

N14 Page 8-51

Loading...

Loading...