(5)Fan is working in good condition

8.2 Periodic Preservation and Maintenance

8.2.1 Periodic Maintenance

Cut off the power when inverter is maintained thermally, check after the main circuit power

indicator light is off. The checking content is shown in Table 8-1.

T

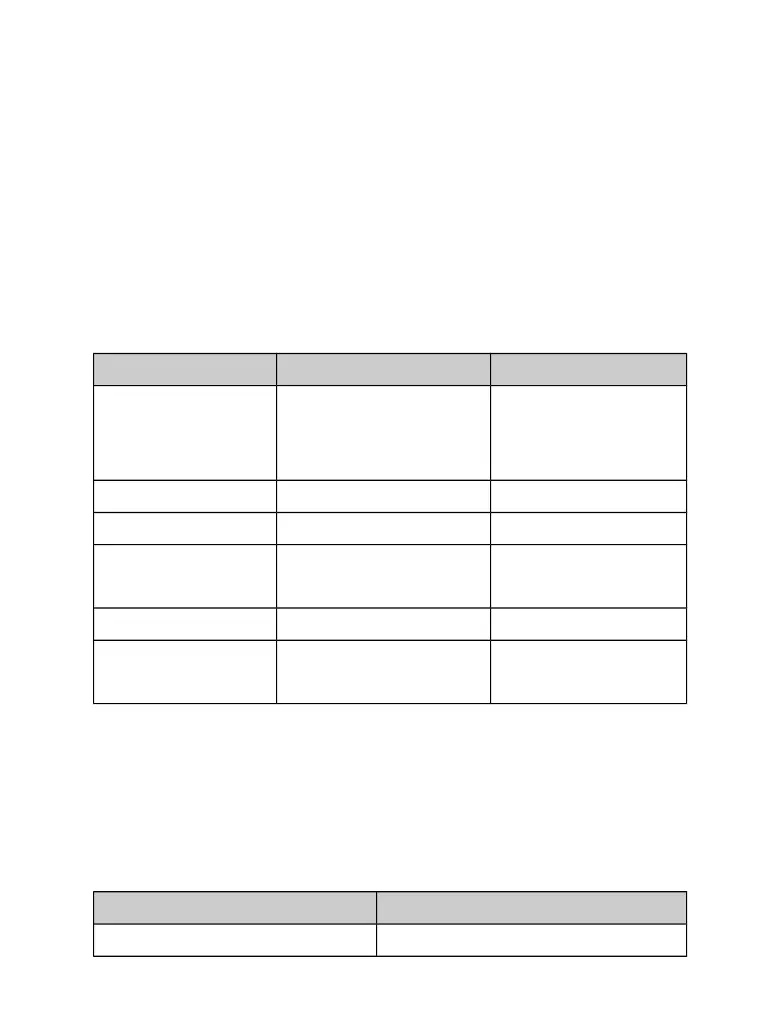

able 8-1 Periodic inspections

Checking item Checking content Troubleshooting

Screws of control

terminals and main

circuit terminals

The screws are loose or not If loose, tighten them with

screw driver

Heat sink Whether there is dust Clean thoroughly the dust

Printed circuit board Whether there is dust Clean thoroughly the dust

Cooling fans Whether there is abnormal

vibration or abnormal noise

Replace cooling fans

Power element Whether there is dust Clean thoroughly the dust

Electrolytic capacitor Whether there is discoloring,

peculiar smell

Replace electrolytic

capacitor

8.2.2 Thermally maintaining

In order to let inverter work well for a long term, user must maintain the inverter thermally.

The replace time of element of inverter is shown in Table 8-2.

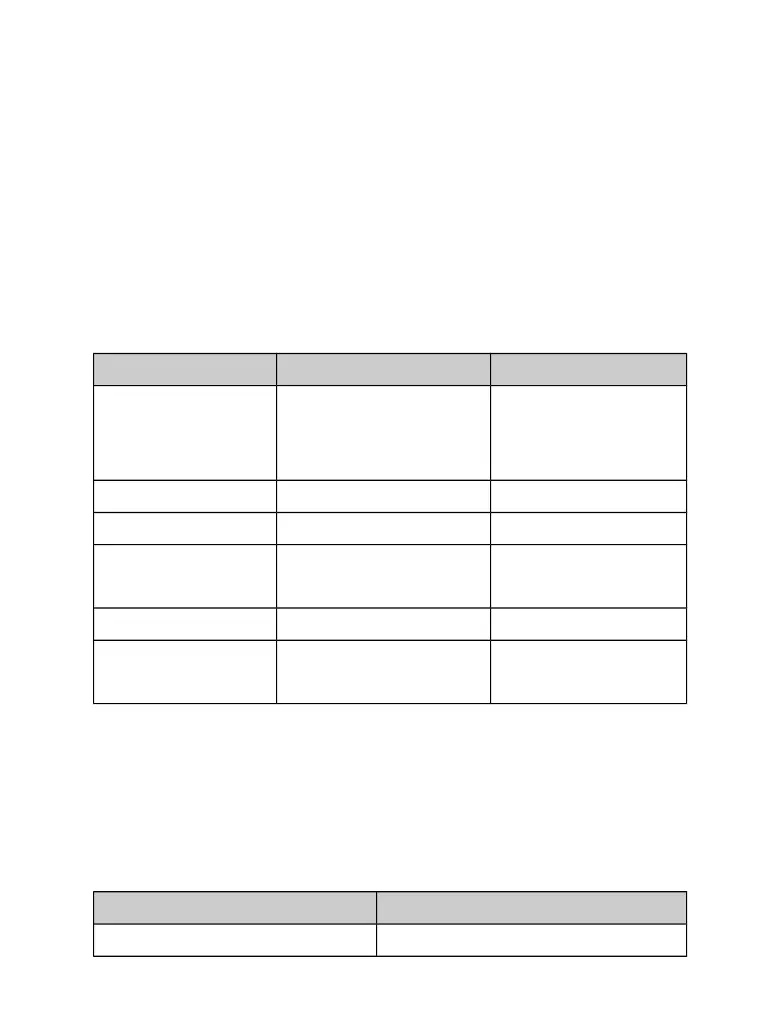

Table 8-2 frequency inverter parts replacement

Items Time criterion

Cooling fans 2-3 years

Loading...

Loading...