166

OILING SYSTEM

OILING SYSTEM TESTS

Observe oil flow through all oil distribution hoses.

Air must be purged during the priming procedure.

Small bubbles are acceptable. La rge b ubbles

must be eliminated through continued priming.

Repair any fuel or oil leaks.

The o iling system on th ese models can also be

primed using the Self-Winterizing feat ure if diag-

nostics software is not available . Refer to STOR-

AGE on p. 45.

OILING SYSTEM TESTS

IMPORTANT: Always perform visual inspections

to identify oiling system lea ks. Make sure th e oil

tank is filled and oil supply is not contaminated.

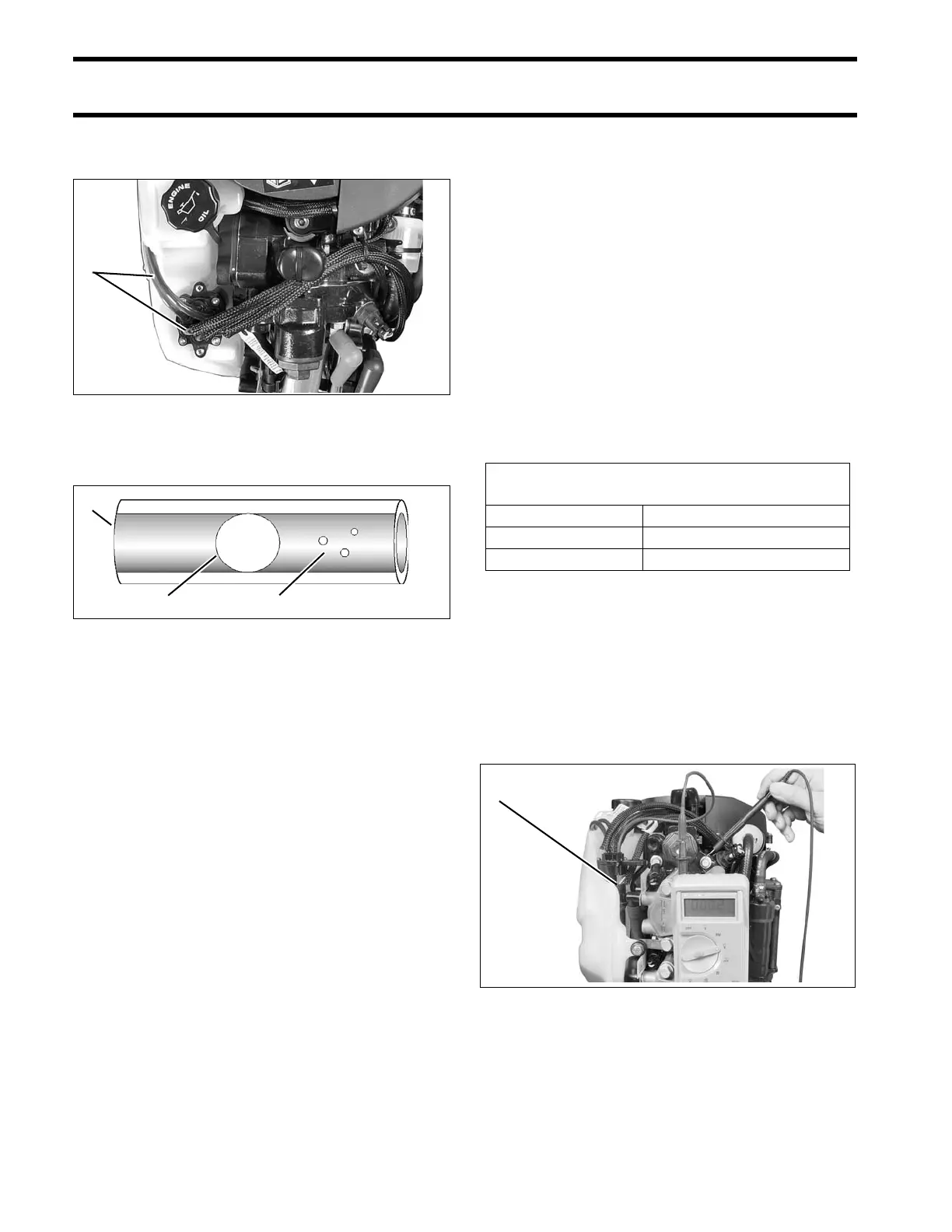

Oil Injection Pump Voltage Tests

IMPORTANT: Do NOT perform static tests using

Diagnostic Power Supply T ool, P/N 587005, with

internal 9 volt batteries only . This will p roduce

false results. Refer to Communication on p. 63.

The EMM controls the pump by providin g ground

through p in 2 3 (blue wire ) of th e J1-B co nnector

and pin B (blue wire) of the oil pump connector.

Use a digital multimeter calibrated to a scale th at

reads 12 V (DC) to mea sure voltage between the

oil pump electrical connector and engine ground.

Connect negative meter lead to ground.

Use an appropriate test probe to connect positive

meter le ad to pin B (b lue wire) of oil injection

pump electrical connector.

Turn th e key switch to the ON positio n. Observe

voltage at pin B.

• Voltage at pin B should be approximately 12 V.

1. Oil distribution hoses 007997

1. Oil distribution hose

2. Small bubbles

3. Large bubbles

004398

Acceptable Oil Injection Pump

Test Readings

Key switch ON approximately 12 VDC

Control signal approximately 5 Hz

Engine running approximately 55 VDC

1. Oil injection pump electrical connector 008065

Loading...

Loading...