338

GEARCASE SERVICE, 75 – 90 HP MODELS

GEARCASE ASSEMBLY

between the gauge bar and the bea ring h ousing

between each pair of scre w holes. Replace the

bearing housing and re peat check if va riance is

greater than 0.004 in. (0.101 mm).

Check squareness of the pinion to the driveshaft.

Hold the shim g auge bar ag ainst the bearing

housing (between the scre w holes) while rotating

just the driveshaft and pinion assembly. Mea-

sure clea rance between the gauge bar and the

pinion at se veral locatio ns. If varia nce is gre ater

than 0.002 in . (0.050 mm) replace the pinion or

driveshaft, as necessary, and repeat check.

Subtract the averag e clearan ce measurement

from 0.020 in. (0.508 mm) to determine the cor-

rect shim thickness req uired. Sele ct t he fe west

number of shims to achieve the correct thickness.

Remove the drivesha ft from the tool and add the

required shims b etween the bearing housing and

the thrust washer.

IMPORTANT: Use extreme care when removing

bearing housing to avoid damaging the seals. Use

Driveshaft Seal Protector, P/N 318674.

Check clea rance again. The measurement

between the gau ge bar and pinion should be

0.020 in. (0.508 mm).

Remove t he nut an d pinion from the driveshaf t.

Discard the nut.

GEARCASE ASSEMBLY

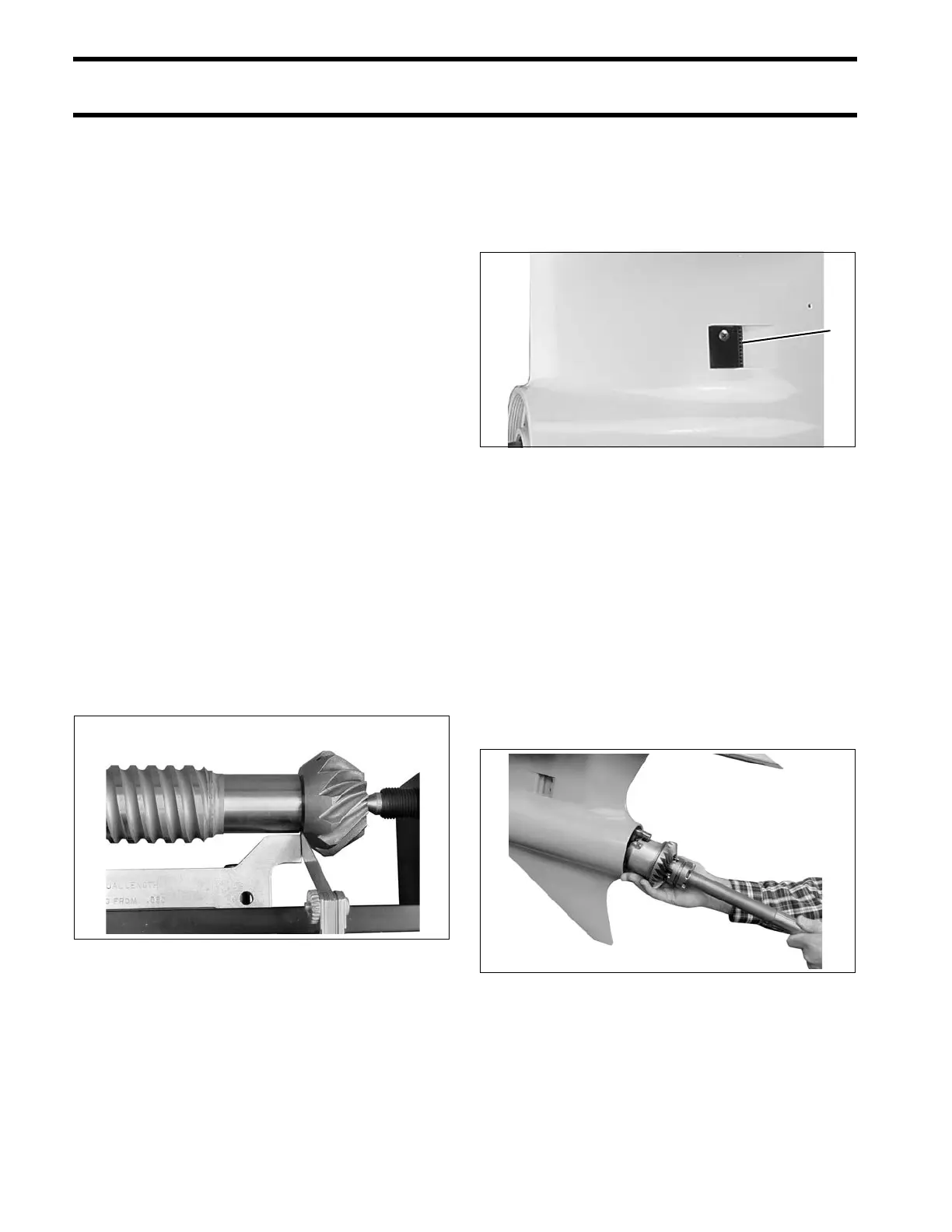

Water Intake Screens

Install water int ake screens. Tighten screws to a

torque of 60 to 84 in. lbs. (7 to 9.5 N·m).

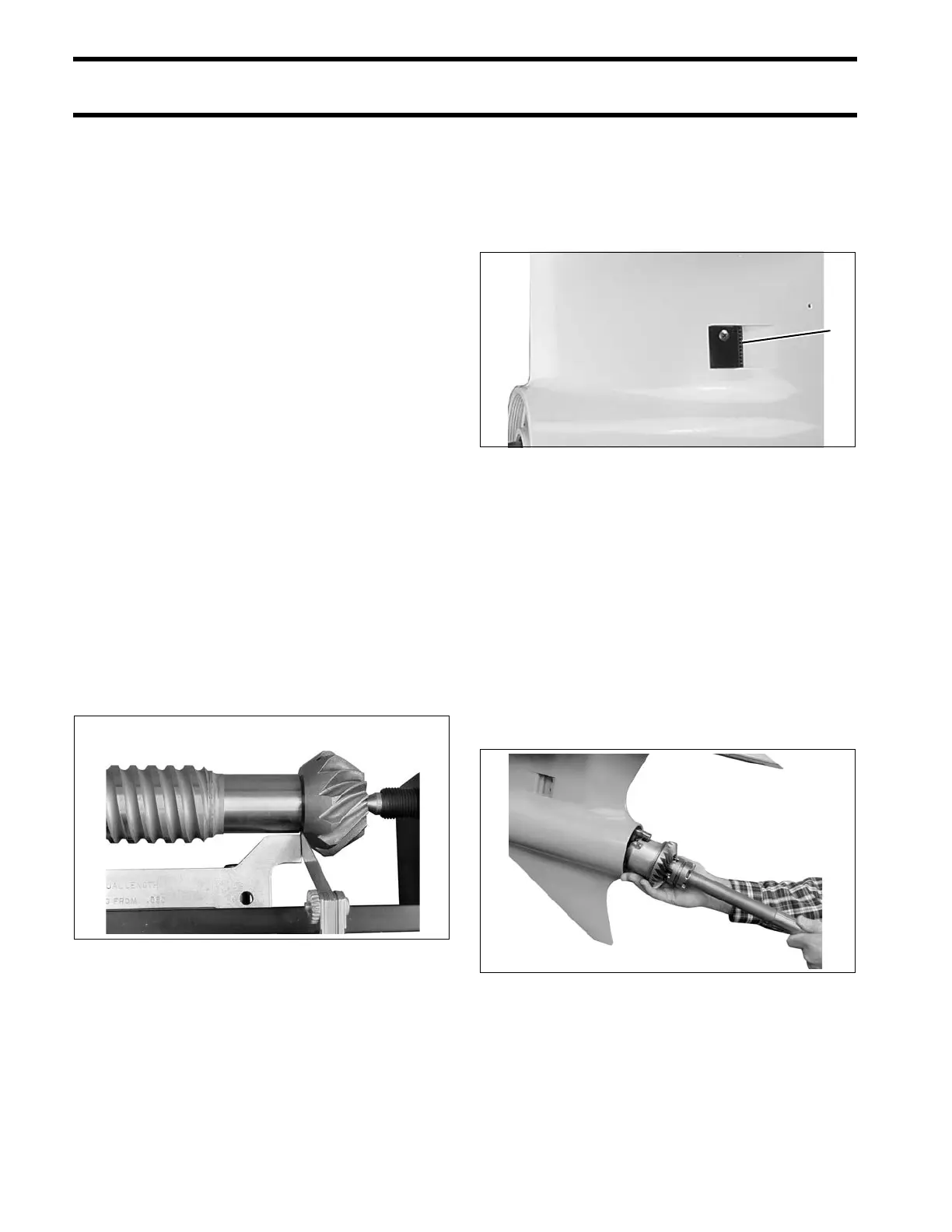

Shift Housing, Gear, and

Propeller Shaft Installation

Push sh ifter de tent into fa rthest downward posi-

tion. T ip the rea r of the gearcase slightly down-

ward to assist in th e inst allation o f th e shaf t

assembly.

Be sure the thrust bearing and the thrust washer

are in the proper position. Insert the shaft assem-

bly fully in to the gea rcase wh ile aligning shif t

housing pin wit h hole in forward e nd of gea rcase

housing.

005417

1. Water intake screen 001991

005427

Loading...

Loading...