200

POWERHEAD

CYLINDER BLOCK CLEANING

CYLINDER BLOCK

CLEANING

IMPORTANT: Before inspecting or assembling

powerhead, all internal components must be com-

pletely clean and free of co ntaminants. Be careful

to avoid damaging any machined surfaces.

Remove any carbon accumula tion from e xhaust

port areas.

Remove any carbon accumulation from cylin der

head combustion chambers.

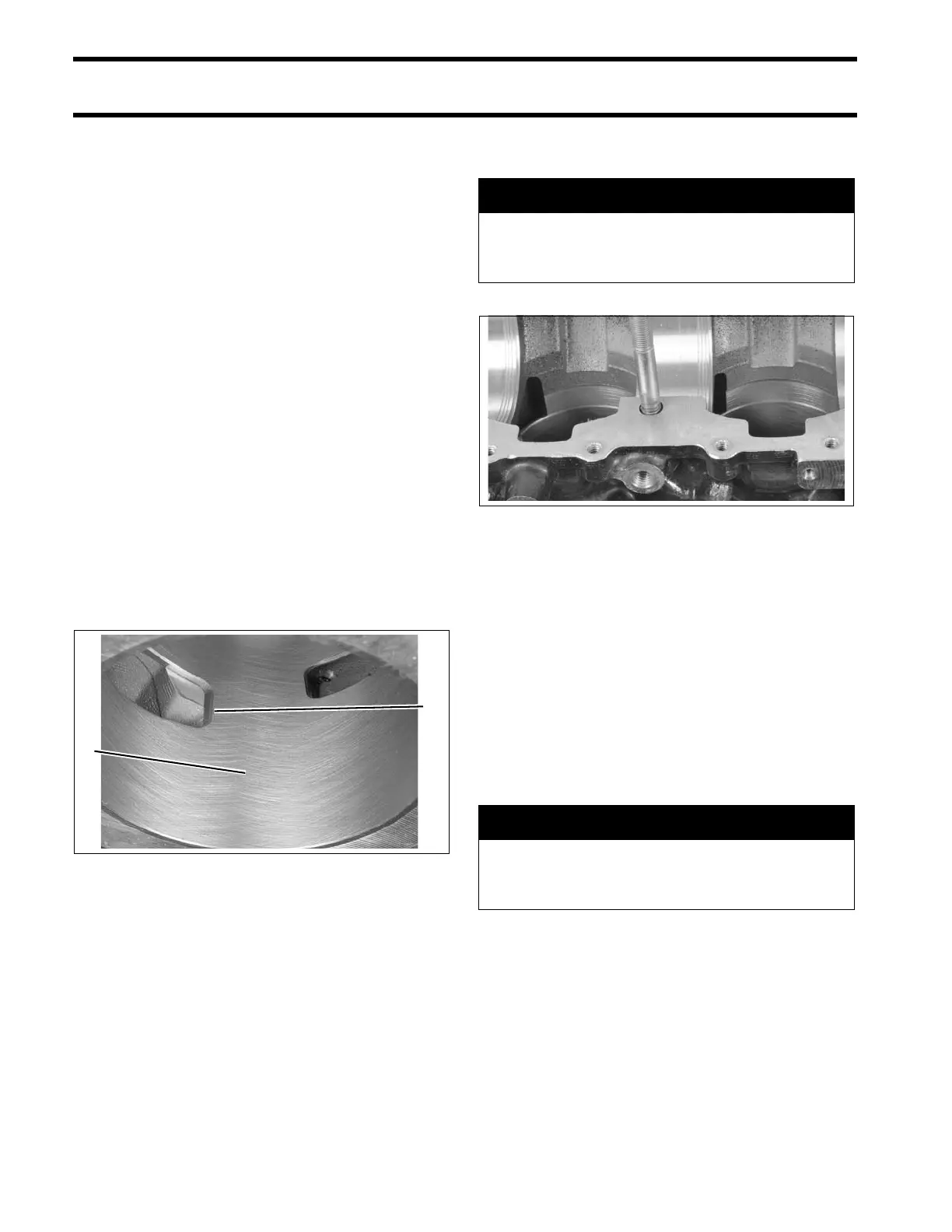

If cylinder walls are glazed from extende d use,

use a rigid, medium grit cylinder hone to resurface

walls. Use slow RPM for best oil retention and ring

sealing. W hen finished, a cro ss hatch p attern of

22 to 32° sh ould be visible in the cylinder wall.

The pattern should be uniform in both directions.

IMPORTANT: To avo id piston or cylind er block

damage, restore the chamfer to all port edge s

using a ball hone or other suitable tool.

Use Gel Seal and Gasket Remover to remove all

traces o f g askets, adhesives, and Gel-Seal II™

sealant from th e cylinder block, crankcase, cylin-

der head, and water cover.

Carefully rem ove an y carbon ac cumulation from

the tops and ring groo ves of the piston using

Engine Tuner. A ring groove cleaning tool can be

made by brea king an o ld ring and grind ing an

angle on it s end. Do not damage ring grooves

while cleaning.

Thoroughly wash en tire cylinder block and crank-

case with warm, soapy water to remove all traces

of contaminants.

Air dry cylind er block and crankcase. Blow all

holes and passageways with compressed air.

Cover the cylinder walls with a libera l amount of

outboard lubricant to prevent corrosion.

1. Crosshatch pattern in cylinder wall

2. Chamfered port edge

002067

A WARNING

To avoid personal injury, wear eye protec-

tion and rubber gloves when using Gel

Seal and Gasket Remover.

002068

A WARNING

To avoid personal injury, wear eye protec-

tion and set compressed air pressure at

less than 25 psi (172 kPa).

Loading...

Loading...