201

POWERHEAD

POWERHEAD INSPECTION

10

POWERHEAD

INSPECTION

For d imensions, refer t o SERVICE SPECIFICA-

TIONS on p. 10.

IMPORTANT: Before any inspect ion pro cess

can begin, all internal components must be co m-

pletely clean and free of contaminants.

Visually inspect all p arts. Check for unusual wear

patterns, scuf fing, or dete rioration o f aluminu m

parts, heat-related d iscoloration of be arings a nd

bearing surfaces, and broken components.

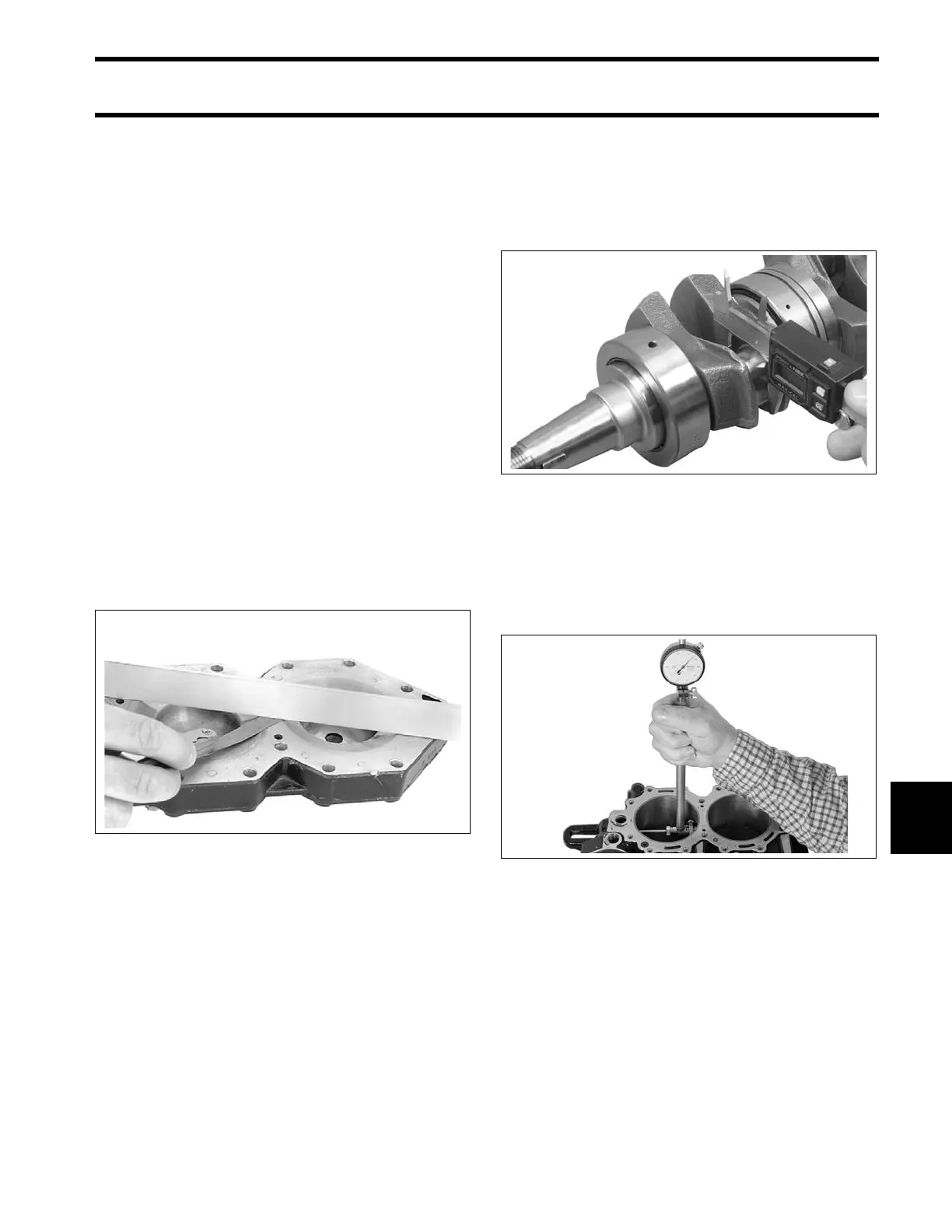

Cylinder Head

Check for cylinder head warpage using a piece of

bar stock or mach inist’s straightedge and a feeler

gauge set.

Cylinder head warpage must not exceed 0.006 in.

(0.15 mm) per inch of me asurement. Re place

head if warpage exceeds this dimension.

Check fuel deflector pins for damage.

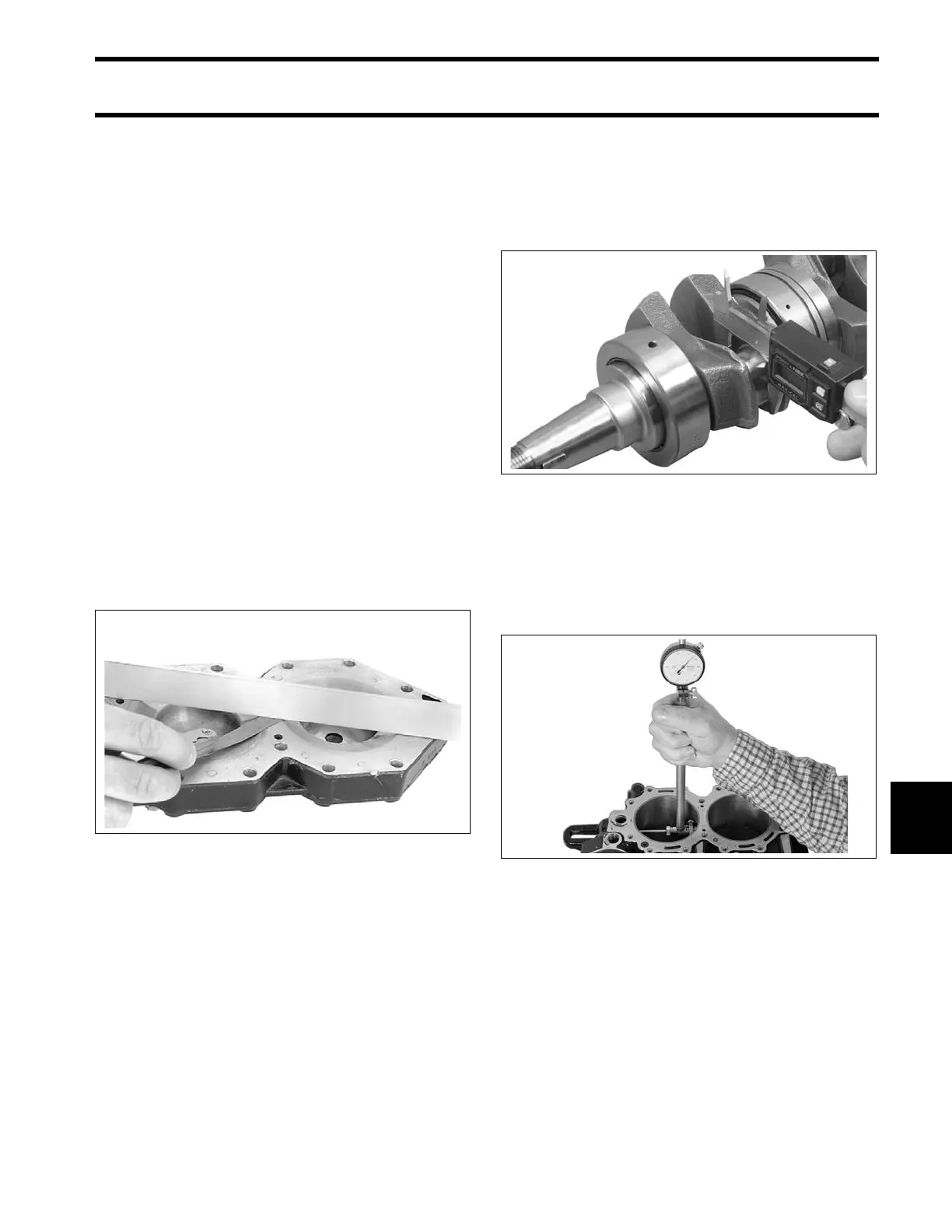

Crankshaft

Measure the diameter of each crankp in and main

bearing journal. The lower main be aring journal

would only b e measu red if the bearing was

removed for another reason.

Cylinder Bore

Use a Cylinder Bore Gauge to inspect each cylin-

der bore for an o ut-of-round, oversize, or t apered

condition. Be sure the gauge is perfectly square in

the bore when measuring.

Measure each cylinder in at least two areas. Each

area should b e measur ed twice. The dif ference

between the two measureme nts in each are a is

the cylinder out-of-round dimension.

• The cylinder must not be o ut-of-round by mo re

than 0.004 in. (0.10 mm).

24423

002142

007283

Loading...

Loading...