75

SYSTEM ANALYSIS

DIAGNOSTIC PROCEDURES

5

Troubleshooting

Outboard will not crank, starter does not

operate:

• Check co ndition of batt ery and cables (ma in

battery switch and cables). Make sure battery

cables are not reversed.

• Confirm that switched B+ is present at “A” termi-

nal (yellow/red wire) of starter solenoid with key

switch in the START position.

• Check g round at “B” te rminal harness conne c-

tion.

• Refer to ELECTRIC START TESTS on p. 102.

Repair starter or start circuit as needed.

Outboard cranks, will not start:

• Check emergency stop switch and lanyard

• Check powerhead mounted neutral switch

• Check the EMM LED Indicators for system sta-

tus information. Refer to EMM LED INDICA-

TORS on p. 77.

• Use the Evinrude Diagnostics sof tware

Occurred Faults screen to check for current ser-

vice codes. If there are multiple occurred sensor

codes, inspect all 5 V sensor circuits for broken

or grounded wiring.

• Perform a Static Ign ition test using Evinrude

Diagnostics so ftware and a n ind uctive t iming

light. Refer to Static Ignition Test on p. 81.

• If ignition test indicates steady sp ark, refer to

FUEL DELIVERY TESTS on p. 84.

Outboard runs, low on power, misfires:

•

Check the EMM LED Indicators for system sta-

tus information. Refer to EMM LED INDICA-

TORS on p. 77.

• Use the Evinrude Diagnostics software Monitor

screen to check syste m (55 V) and TPS vo lt-

ages. System volt age should b e steady , a nd

TPS voltage should be between 0.2 and 4.85 V.

IMPORTANT: Use a digital multimeter to check

voltage on external circui ts only when necessary.

All EMM output currents are DC current.

• Use the diagnostics software Dynamic Tests to

isolate a faulty cylinder. See DYNAMIC TESTS

on p. 76.

• Use an inductive timing light to check ig nition

and fuel injector circuits. Refer to Running Igni-

tion Tests on p. 82 and Running Fuel System

Tests on p. 85.

• Use the diagn ostics software Fuel Control

Adjustment test to help identify a cylind er that

may be too rich or too lea n. Refer to Fuel Con-

trol Adjustment on p. 76.

• Use an inductive amp meter to monitor injector

circuit current. Compare readings of all circuits

to identify possible failure.

• Check fuel quality and that fuel is present at

injectors.

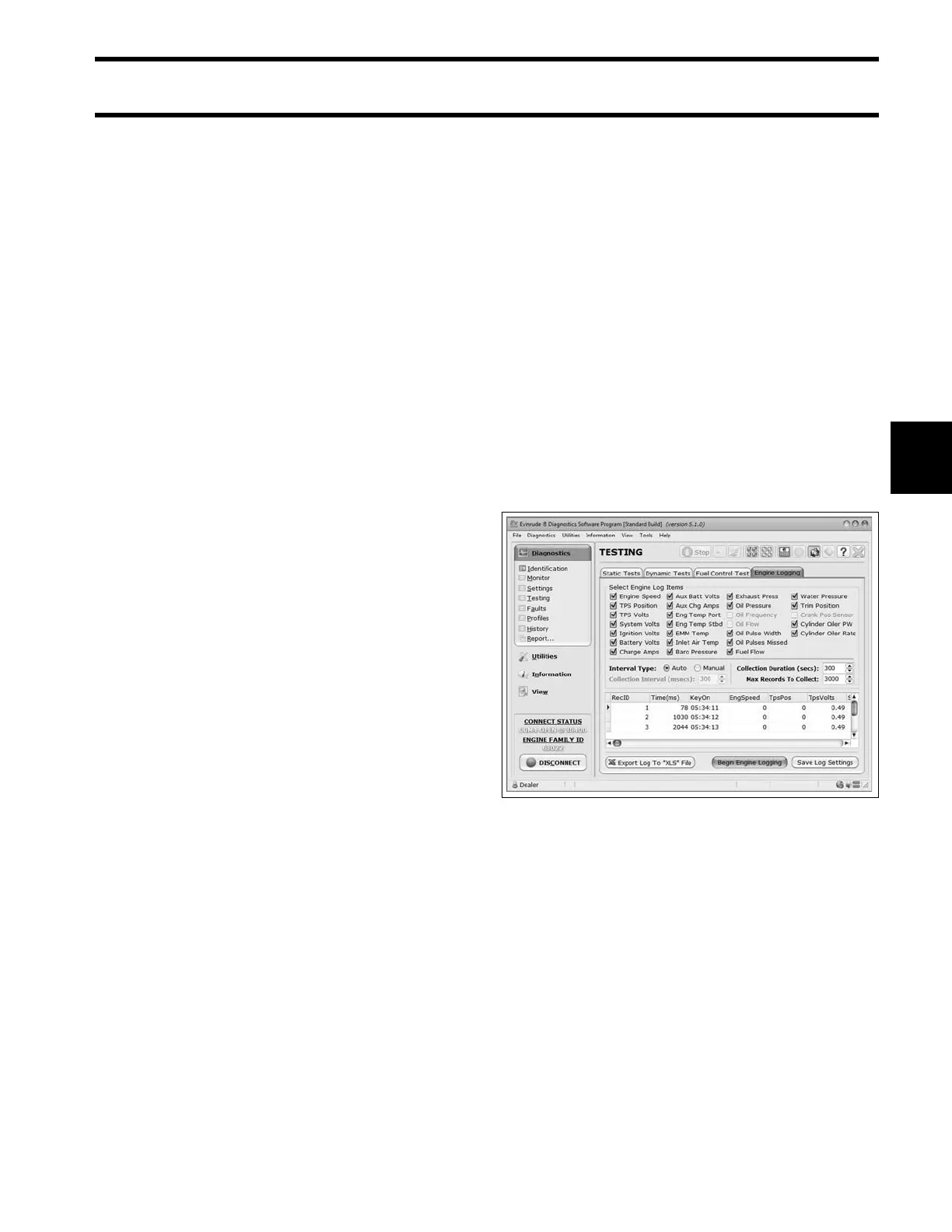

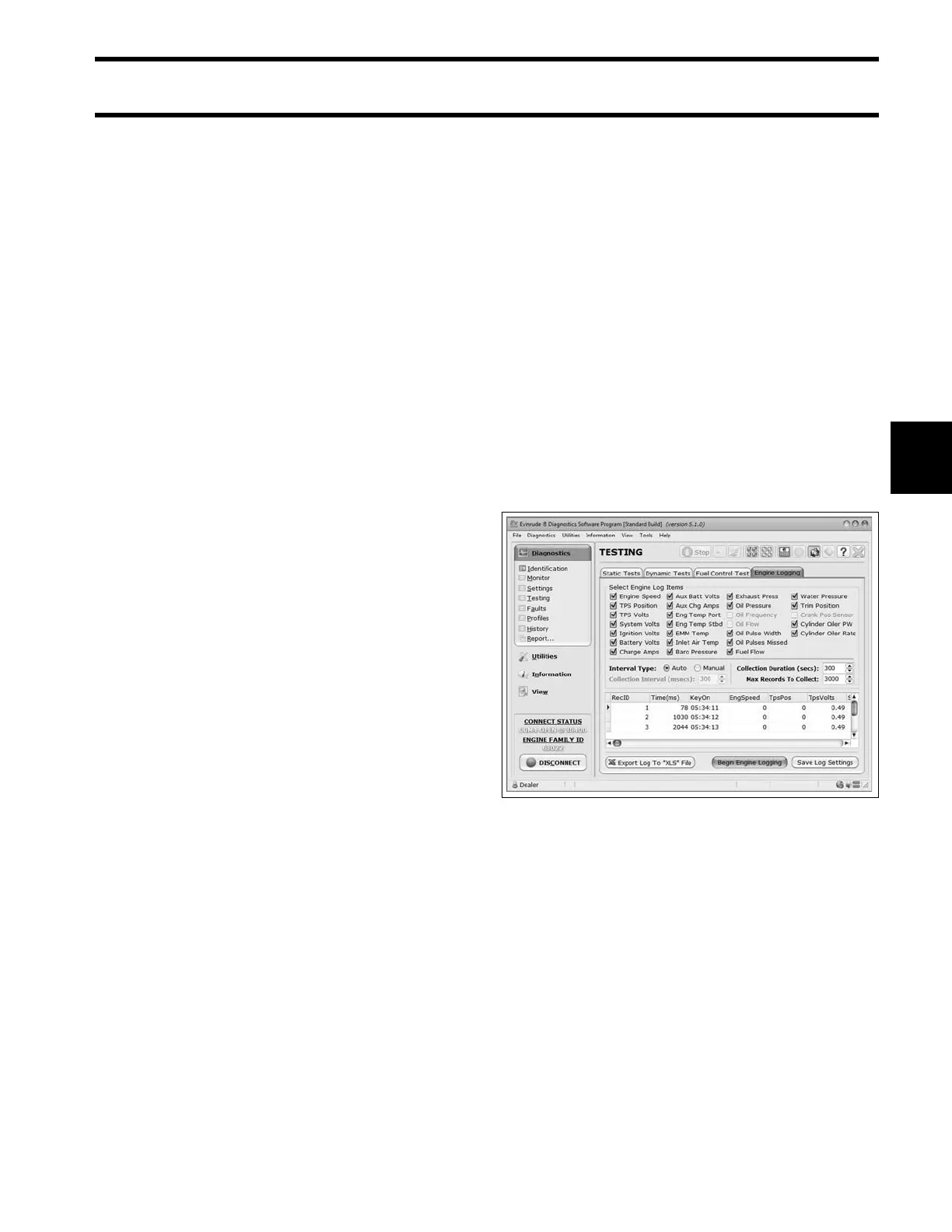

• Use the diagnostics sof tware Logging fun ction

to record engine data as a problem is occurring.

• AFTER all the above inspections, if the cause of

a running quality problem still cannot be identi-

fied, perform a compression test to check for

internal powerhead damage.

IMPORTANT: Remove a cylinder head or disas-

semble the engine only as a last resort.

Logging Screen 008574

Loading...

Loading...