74

SYSTEM ANALYSIS

DIAGNOSTIC PROCEDURES

DIAGNOSTIC

PROCEDURES

Visual Inspections

Inspect wiring and electric al connectio ns. Disas-

semble a nd clean all corrode d co nnections.

Replace damaged wiring, con nectors, o r termi-

nals. Repair any shorted electrical circuits.

• Refer to ELECTRICAL HARNESS CONNEC-

TIONS on p. 92.

• Refer to WIRING DIAGRAM at the back of this

manual.

• Refer to CONNECTOR SERVICING on p. 116.

Make su re all g round connections are clean a nd

tight. Refer to GROUND CIRCUITS on p. 94.

Inspect spark plugs for wea r, oil fowling, or dam-

age. A rich or lean running condition or evidence

of internal eng ine da mage could be identified b y

the appearance of the spark plugs.

Check the fuse an d the emergency st op switch

lanyard.

Operational Inspections

Run the ou tboard to confirm actual symp toms

before perfo rming any unne cessary procedures.

Inspection should include the following:

• Make sure th e outboard can be cranked easily,

with no mechanical binding.

• Check the EMM LED Indicators for system sta-

tus information. Re fer to EMM LED INDICA-

TORS on p. 77.

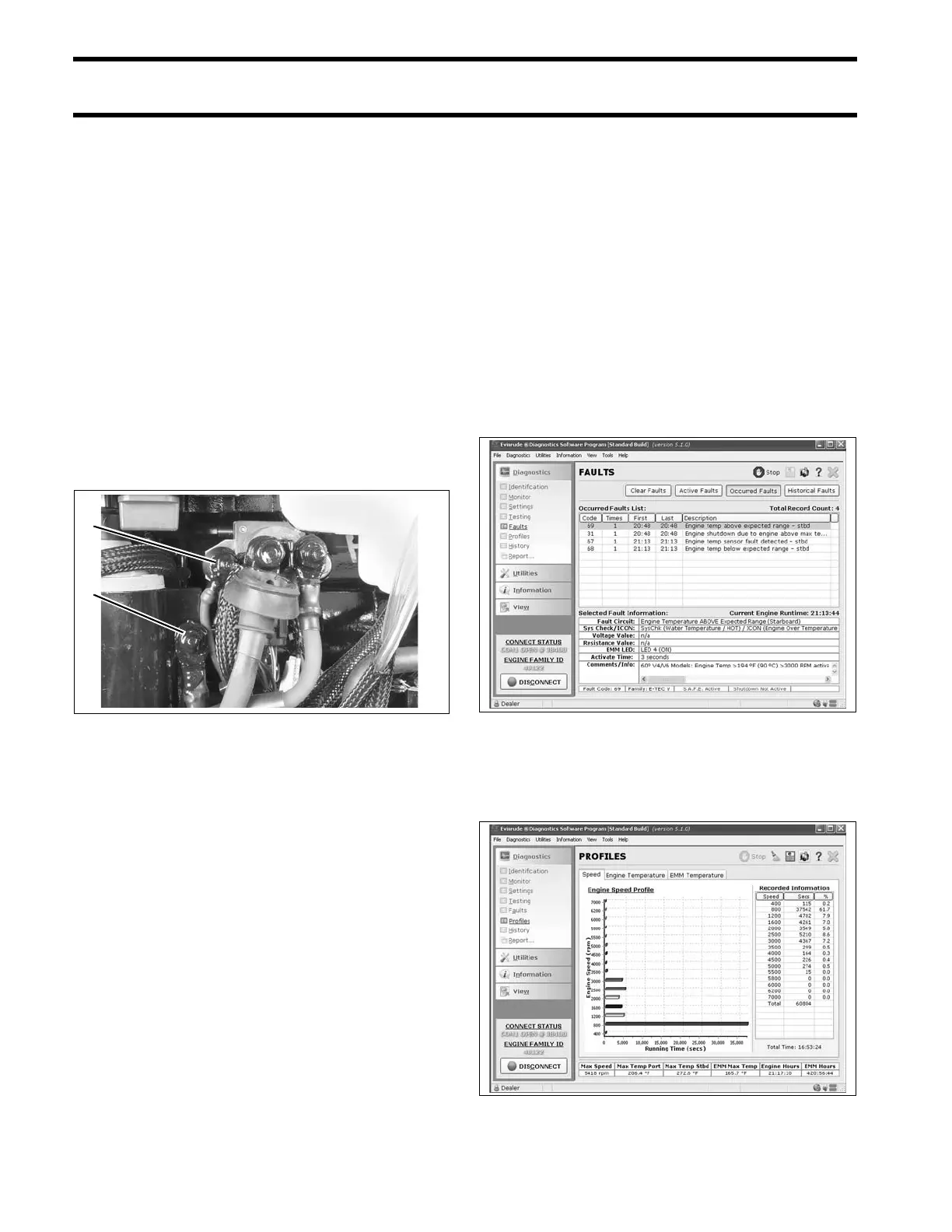

• Check the Evinrude Diagnostics software Active

Faults and Occurred Faults screens for current

service codes. Correct a ny problems and clear

the codes before further troubleshooting. Refer

to Occurred Service Codes (Faults) on p. 65.

Check the diag nostics software Profiles,

Occurred, and Historical Faults screens for evi-

dence of abnormal operation.

1. Main engine harness ground

2. Ground stud (battery)

002292

Occurred Faults Review Screen 008584

Profiles Screen 008587

Loading...

Loading...