203

POWERHEAD

POWERHEAD ASSEMBLY

10

POWERHEAD

ASSEMBLY

IMPORTANT: Proceed slowly . Make no forced

assemblies unless a pressin g opera tion is called

for. All interna l components must be perfectly

clean and lightly coated with outboard lubricant.

IMPORTANT: Use new wrist pin retaining rings,

gaskets, seals, and O-rings during assembly.

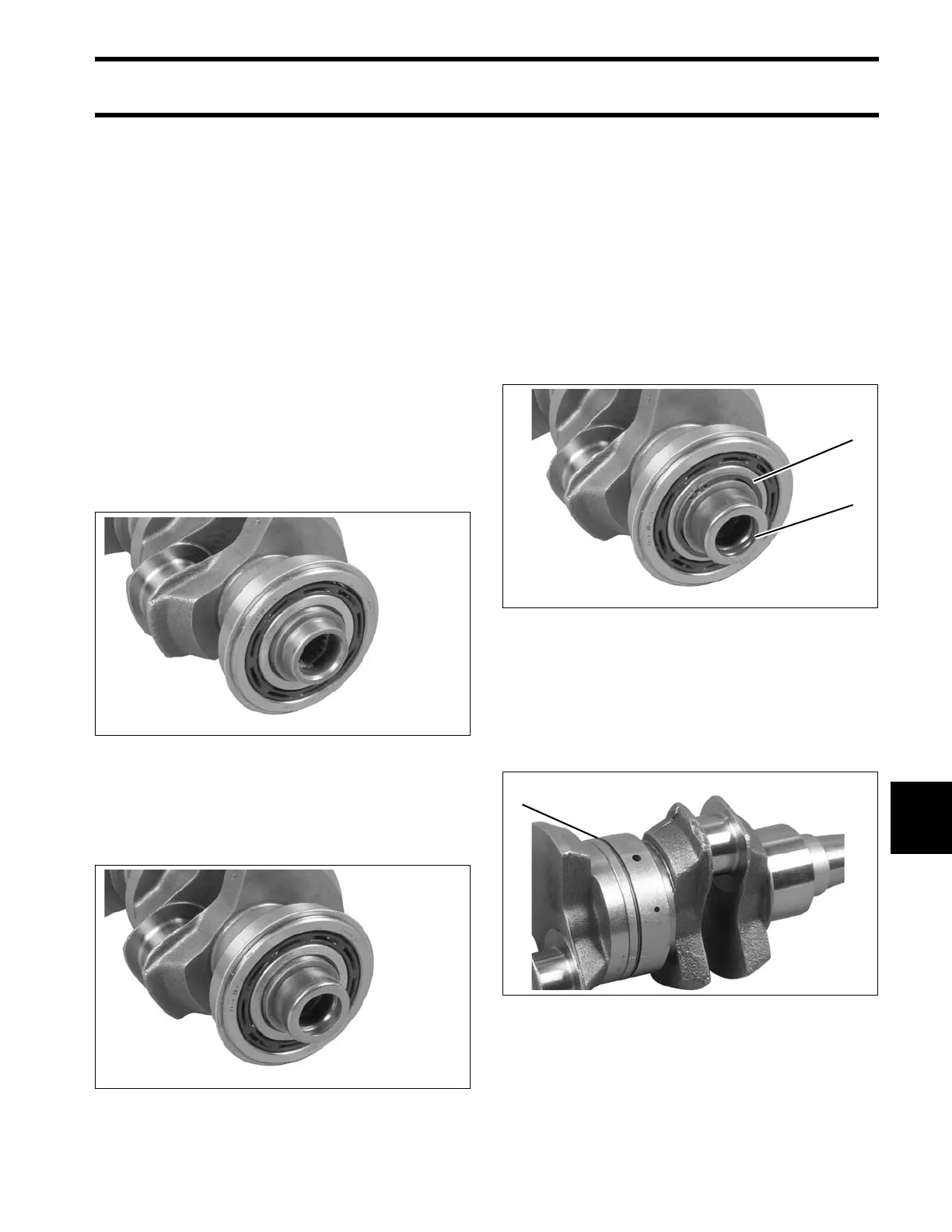

Crankshaft Assembly

Oil the end of the cra nkshaft. Use Crankshaf t

Bearing/Sleeve Installer, P/N 338647, and place a

new lower main bearing onto crankshaft with let-

tered side facing th e tool. Inst all bearing un til it

seats on the crankshaft.

Oil the end of the cra nkshaft. Use Crankshaf t

Bearing/Sleeve Inst aller, P/N 338647, to drive a

new sleeve o nto the crankshaft until the installer

contacts the lower main bearing.

If the inst aller sticks on the sleeve af ter installa-

tion, thread Slide Hamme r, P/N 391008, in to

installer and pull it off.

IMPORTANT: Inspect sleeve af ter inst allation.

Sleeve must not be used if surface is damaged.

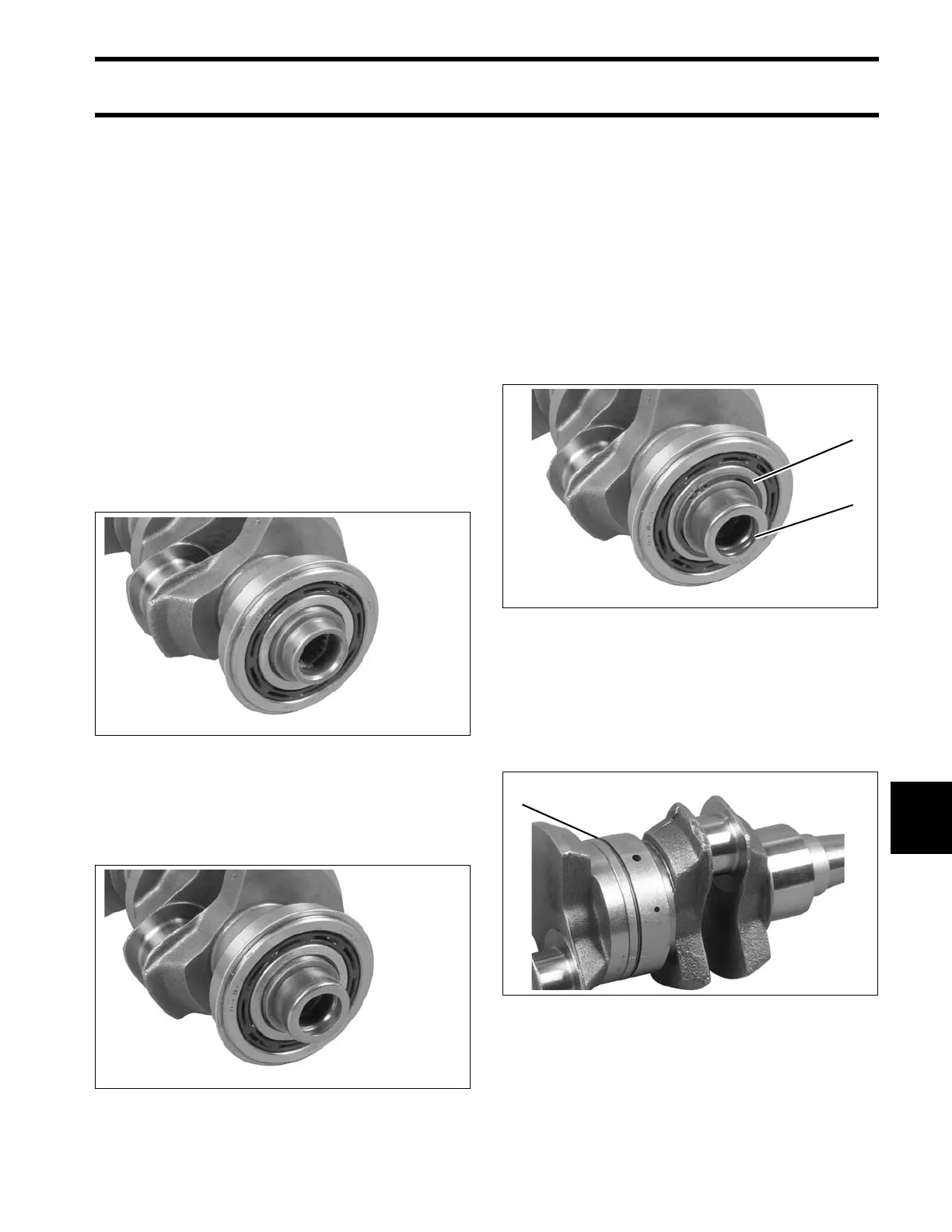

Use retaining ring pliers to install bearing retaining

ring with sharp edge facing away from bearing.

Lubricate a new driveshaft O-ring and lightly lubri-

cate crankshaf t splines with Moly Lube. Inst all

O-ring in sleeve.

Lubricate the center main bea rings and split

sleeves with outboard lubricant and install them in

their original positio ns. The split sleeve ring

grooves must face toward driveshaf t (lower) en d

of crankshaft when installed.

Lightly coat the outside edge of a new lower hous-

ing se al with Gasket Sealing Compound. Press

against outer case of the seal to install seal in the

002029

002030

1. Bearing retaining ring

2. O-ring

002031

1. Groove toward driveshaft end 002032

Loading...

Loading...