297

GEARCASE SERVICE, 40 – 65 HP MODELS

GEARCASE REMOVAL AND INSTALLATION

12

Gearcase Installation

Before installing gearcase, shift rod

adjustment MUST be checked. Refer to SHIFT

ROD ADJUSTMENT on p. 300.

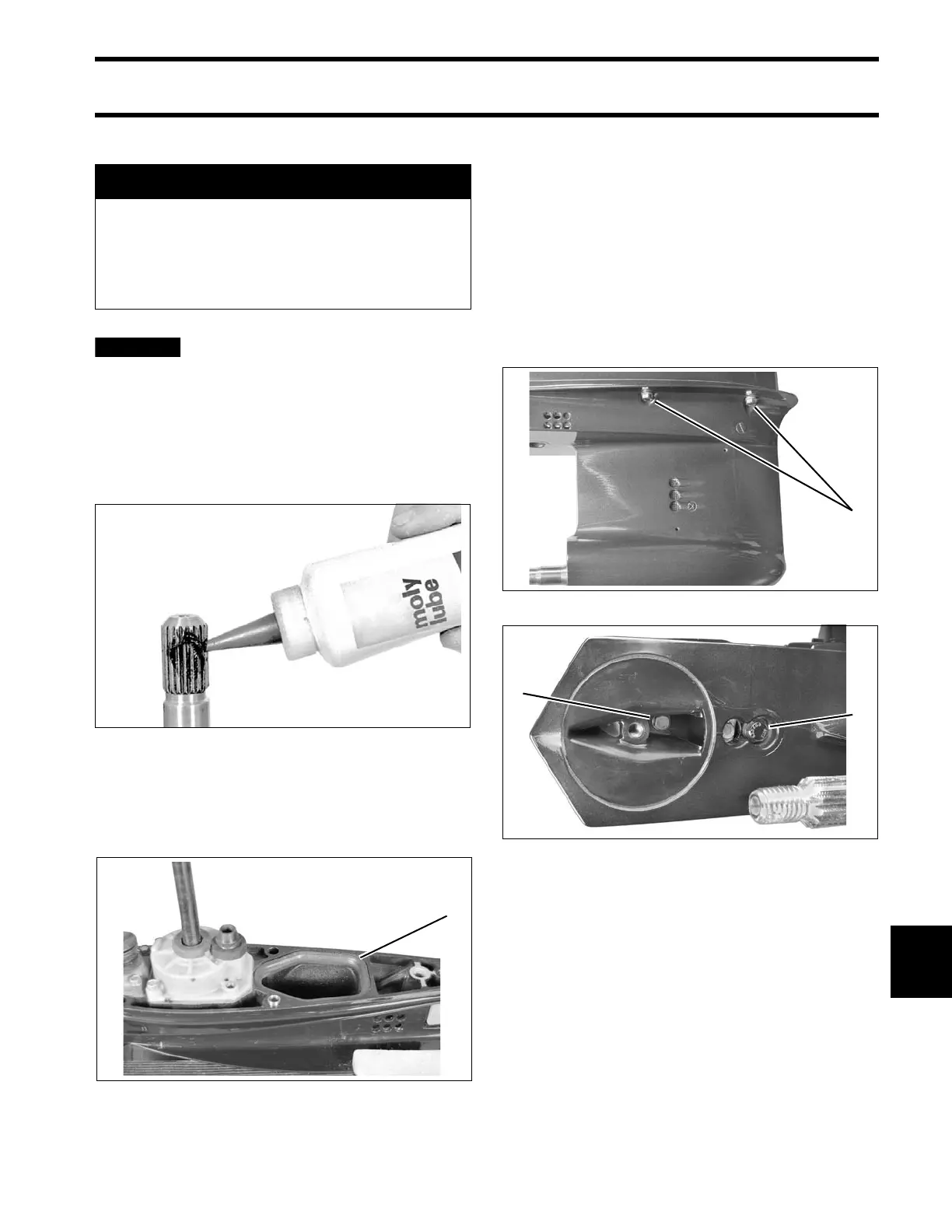

Coat th e drivesh aft splines with Moly Lube. DO

NOT co at top su rface of th e driveshaf t be cause

lubricant may prevent seat ing of the driveshaf t in

the crankshaft.

Apply Adhesive 847 to the exhaust housing seal’s

outer su rface. Place the seal in the ge arcase

exhaust cavity. Apply Triple-Guard grease to the

seal’s inner surfaces.

Slide the gearcase into place, making sure:

• Driveshaft engages the crankshaft.

• Inner exhaust housing installs correctly.

• Shift ro d does not turn an d is positio ned prop-

erly in the shift rod lever below the crankcase.

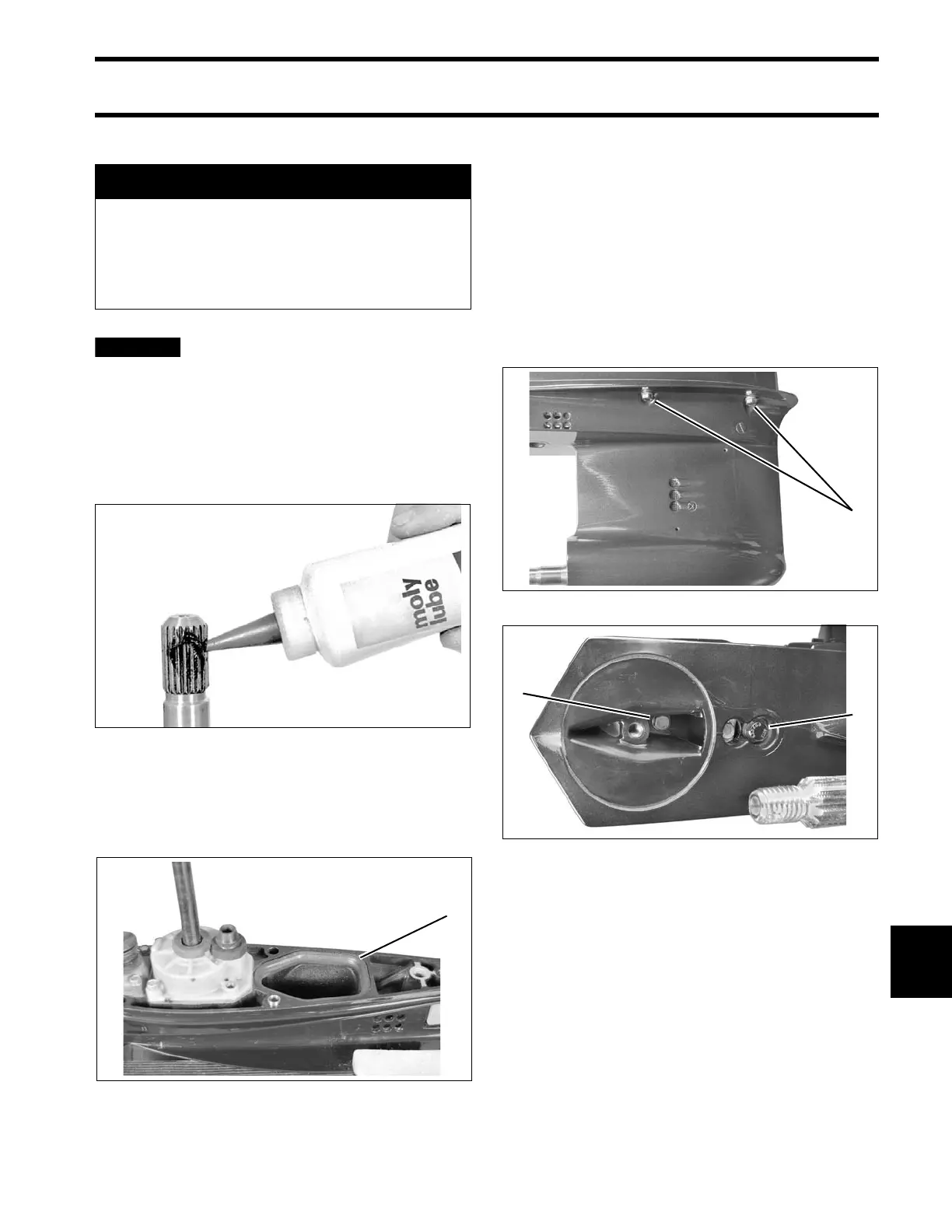

Apply Triple-Guard g rease to th reads o f th e

gearcase retaining screws. T ighten the screws to

a torque of:

• 3/8 in. screws – 18 to 20 ft. lbs. (24 to 27 N·m)

• 7/16 in. screw – 28 to 30 ft. lbs. (38 to 40 N·m)

• 5/16 in. screw – 10 to 12 ft. lbs. (13.5 to 16 N·m)

Apply Triple-Guard grea se to threads of the trim

tab screw. Inst all a nd align th e trim t ab with th e

index ma rks noted prior to disassembly . T ighten

the trim t ab screw to a to rque of 35 to 4 0 ft. lbs.

A WARNING

During service, the outboard may drop

unexpectedly. Avoid personal injury;

always support the outboard’s weight with

a suitable hoist or the tilt support bracket

during service.

30385

1. Exhaust housing seal 008354

1. 3/8 in. screws 001994

1. 7/16 in. screw

2. 5/16 in screw

001995

Loading...

Loading...